Elevator guide rail suitable for high-speed operation

An elevator guide rail, high-speed technology, applied in the field of elevators, can solve the problems of inability to splicing and fix the guide rails, unable to lubricate the elevator guide rails, etc., and achieve the effects of improving convenience, stability and firmness, and facilitating disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

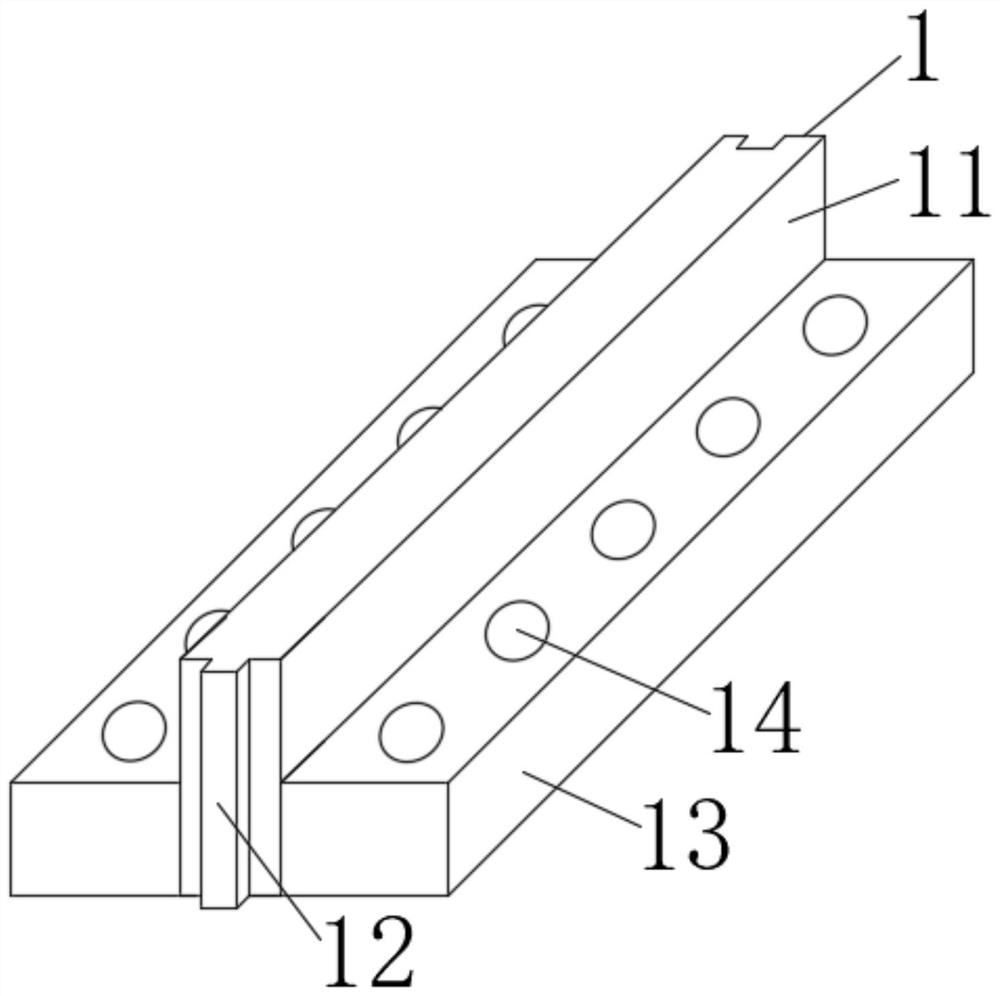

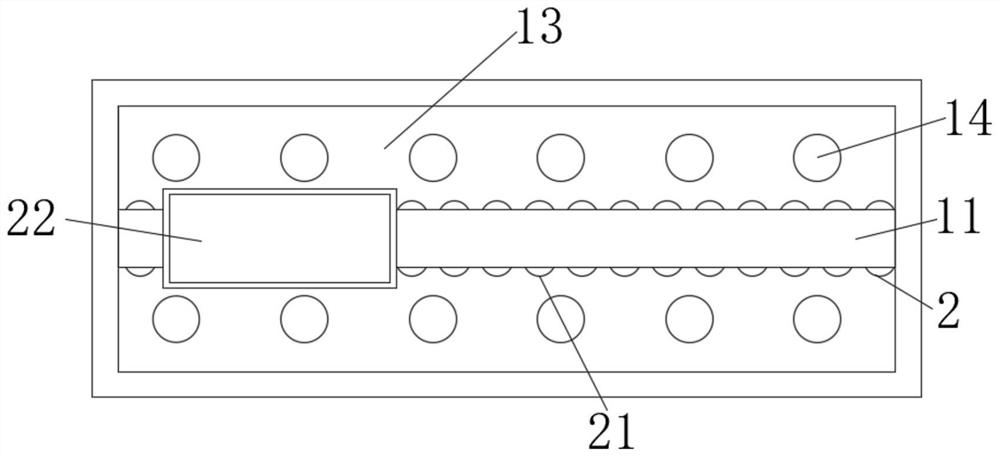

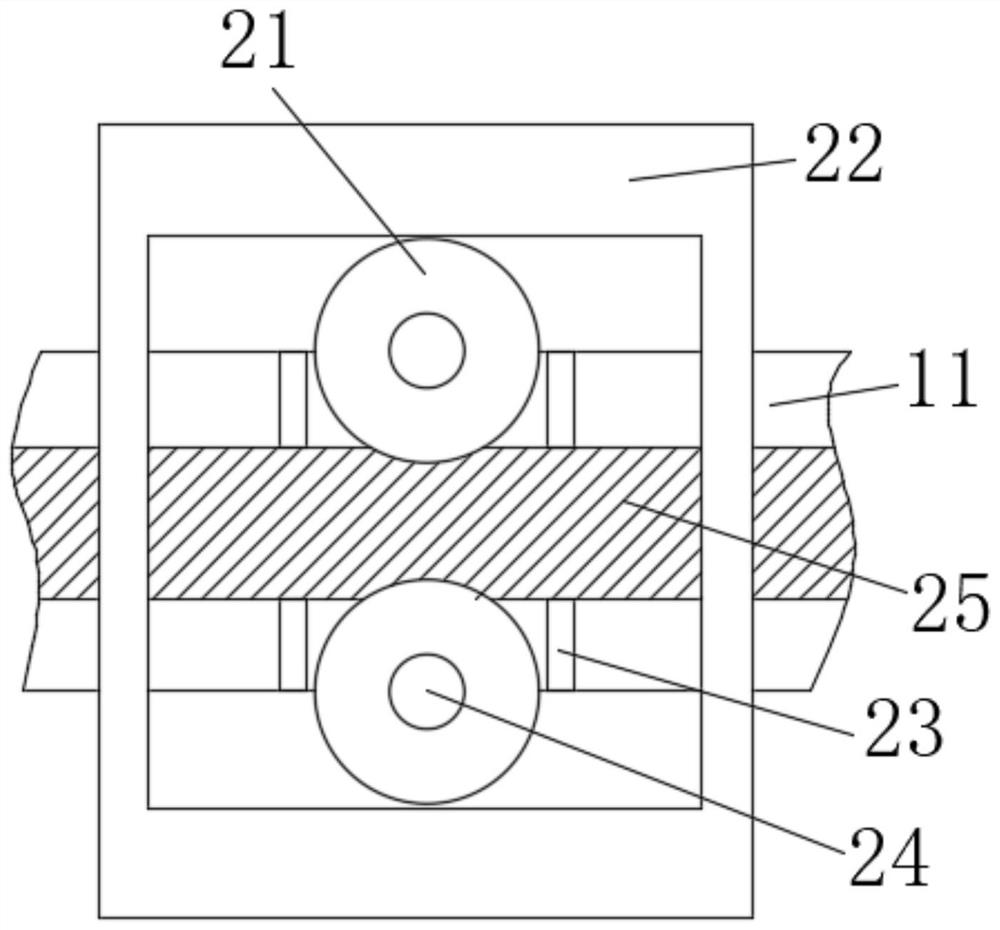

[0021] see Figure 1-4 , an embodiment provided by the present invention:

[0022] An elevator guide rail suitable for high-speed operation, including a device body 1, the device body 1 includes a first connecting block 11, two ends of the first connecting block 11 are connected with splicing blocks 12, and the outer surface of the first connecting block 11 is fixedly connected with The second connecting block 13, the inside of the second connecting block 13 is provided with a through hole 14, the inside of the first connecting block 11 is connected with a lubricating mechanism 2, and the lubricating mechanism 2 includes a lubricating wheel 21, and the inside of the first connecting block 11 is connected with a lubricating mechanism 2. Wheel 21, the outer surface of the first connecting block 11 is movably connected with a slide rail 22, the inside of the first connecting block 11 is connected with a lubricating oil pipe 25, the outer surface of the lubricating oil pipe 25 is ...

Embodiment 2

[0025] On the basis of embodiment one, a kind of embodiment that the present invention further provides:

[0026] An elevator guide rail suitable for high-speed operation, including a device body 1, the device body 1 includes a first connecting block 11, two ends of the first connecting block 11 are connected with splicing blocks 12, and the outer surface of the first connecting block 11 is fixedly connected with The second connecting block 13, the inside of the second connecting block 13 is provided with a through hole 14, the inside of the first connecting block 11 is connected with a lubricating mechanism 2, and the lubricating mechanism 2 includes a lubricating wheel 21, and the inside of the first connecting block 11 is connected with a lubricating mechanism 2. Wheel 21, the outer surface of the first connecting block 11 is movably connected with a slide rail 22, the inside of the first connecting block 11 is connected with a lubricating oil pipe 25, the outer surface of t...

Embodiment 3

[0031] On the basis of embodiment two, another kind of embodiment that the present invention further provides:

[0032] An elevator guide rail suitable for high-speed operation, including a device body 1, the device body 1 includes a first connecting block 11, two ends of the first connecting block 11 are connected with splicing blocks 12, and the outer surface of the first connecting block 11 is fixedly connected with The second connecting block 13, the inside of the second connecting block 13 is provided with a through hole 14, the inside of the first connecting block 11 is connected with a lubricating mechanism 2, and the lubricating mechanism 2 includes a lubricating wheel 21, and the inside of the first connecting block 11 is connected with a lubricating mechanism 2. Wheel 21, the outer surface of the first connecting block 11 is movably connected with a slide rail 22, the inside of the first connecting block 11 is connected with a lubricating oil pipe 25, the outer surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com