A prefabricated steel formwork for prefabricated stairs

A prefabricated, steel formwork technology, which is applied to the preparation of building components on site, construction, building construction, etc., can solve the problems of increasing the difficulty of formwork removal, cumbersome installation costs, and nail sinking, so as to facilitate transportation and reduce shaking , Easy to install and disassemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

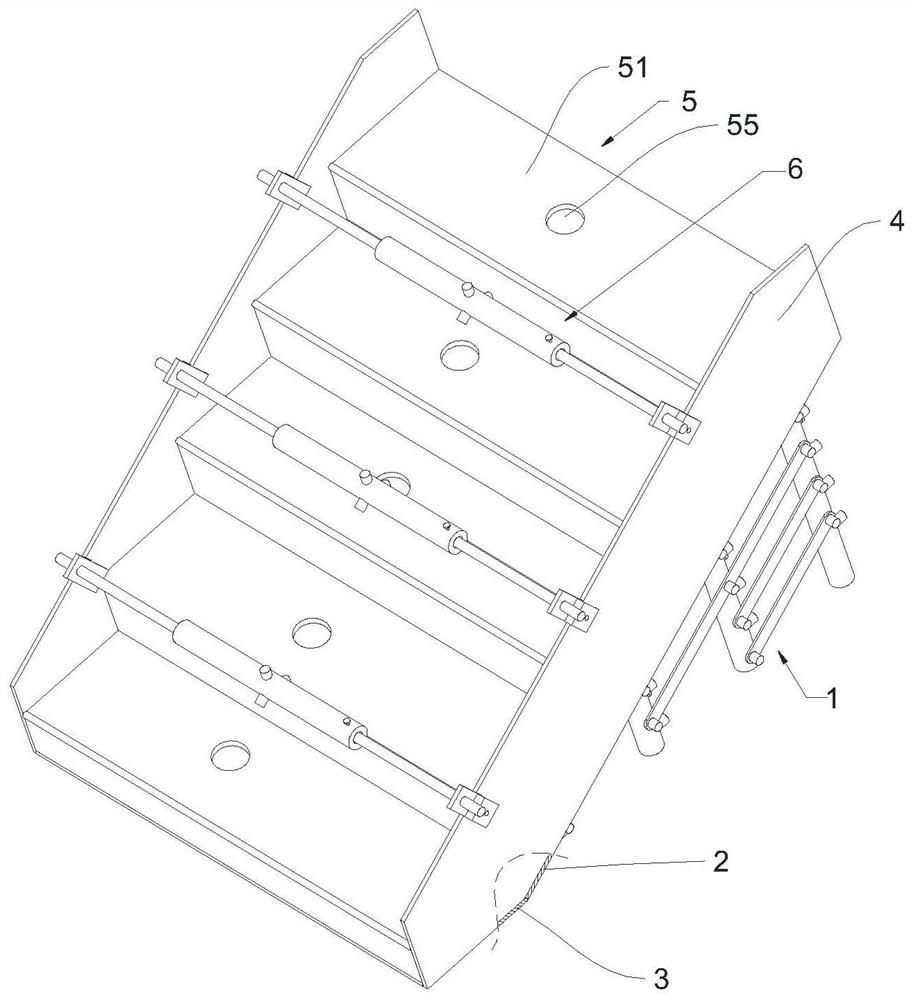

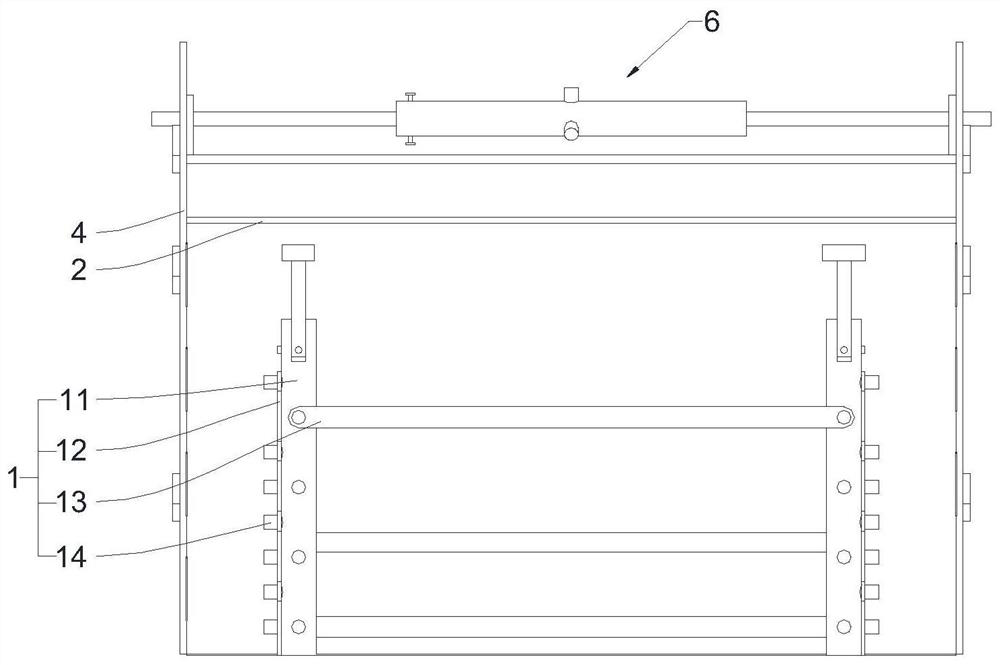

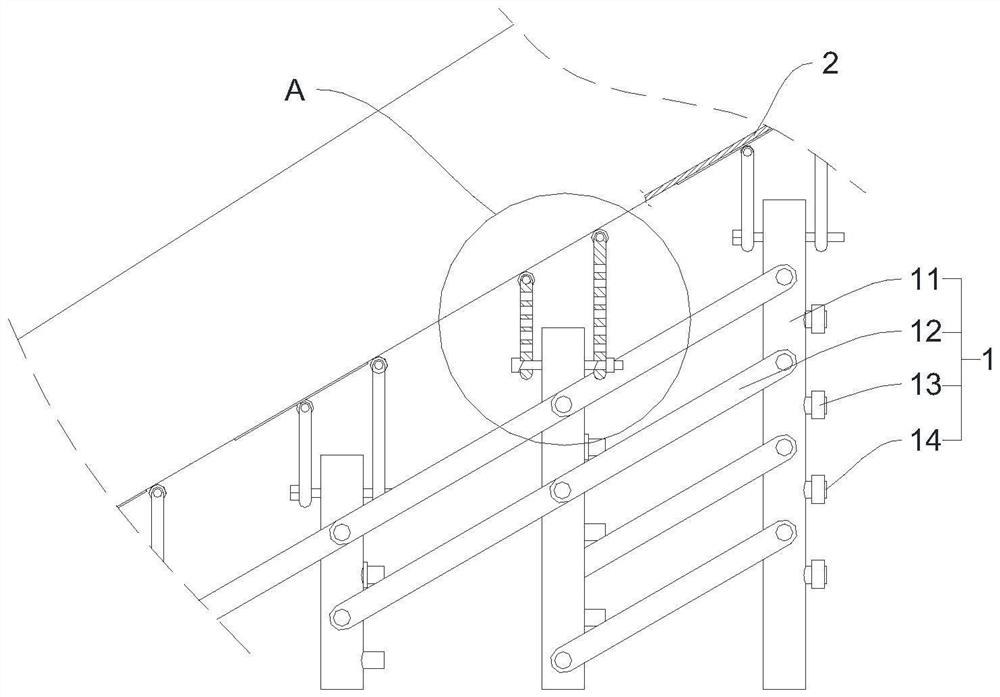

[0036] refer to figure 1 As shown, it is a prefabricated steel formwork for prefabricated buildings disclosed by the present invention, including a support frame 1 on the ground, a first support plate 2 is provided on the support frame 1, and one end of the first support plate 2 is close to the ground A second support plate 3 that is attached to the ground is rotated, and stair side plates 4 are vertically provided on both sides of the first support plate 2, and a stair board module that is rotatably connected to the second support plate 3 is provided between the stair side plates 4 5. A pressing device 6 is provided between the two staircase side panels 4 to drive the two staircase side panels 4 close to each other so as to compress the staircase module 5 . In the actual operation process, first place the second support board 3 on the ground, adjust the prede...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com