Rotary vane type vacuum pump eliminating harmful space

A technology of rotary vane vacuum pump and harmful space, which is applied in the direction of rotary piston pump, rotary piston/swing piston pump components, rotary piston machinery, etc., and can solve the problems such as the decline of the vacuum pumping effect of the vacuum pump and the inability to remove the gas. , to achieve the effect of improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

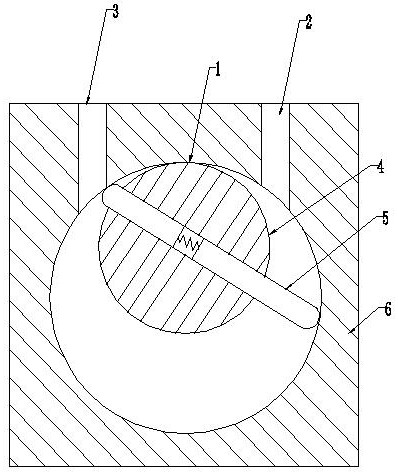

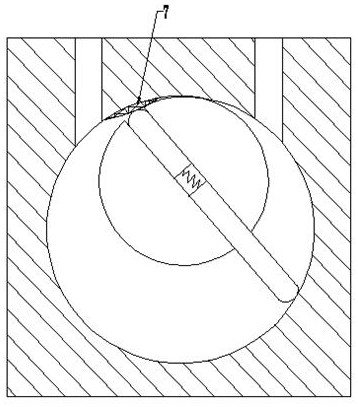

[0030] Such as figure 2 and Figure 5 A protrusion 7 is set between the apex 1 and the mouth of the exhaust pipe 3, the protrusion 7 is a strip along the axial direction of the pump chamber, the protrusion 7 is equal to the rotor 4, and the protrusion 7 The outer edge of the cross section of 7 is a section of arc, the radius of the circle where the arc is located is equal to the section radius of the pump cavity, and the corresponding central angle of the arc is 25 degrees.

Embodiment 2

[0032] One continuous protrusion 7 in Embodiment 1 is changed into several discontinuous protrusions 7 on one axis, and other conditions remain unchanged.

Embodiment 3

[0034] Change the central angle in Example 1 to 20 degrees, and other conditions remain unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com