Method for estimating transient soot emission of engine

An emission and engine technology, applied in the direction of engine testing, measuring devices, machine/structural component testing, etc., can solve the difficulties of transient soot flow estimation, no load correction coefficient type, exhaust transient soot flow error and other problems, to achieve the effect of comprehensive calibration quantitative factors, clear correction factors, and high relative accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following specific implementation methods are used to explain the technical solutions of the claims of the present invention, so that those skilled in the art can understand the claims. The protection scope of the present invention is not limited to the following specific implementation structures. The protection scope of the present invention includes the technical solution of the claims of the present invention made by those skilled in the art and is different from the following specific embodiments.

[0025] In the calibration process of the present invention, corrections under different operating conditions can be considered.

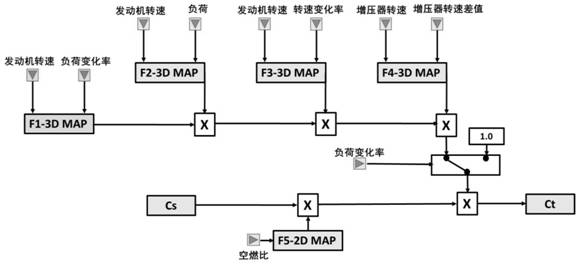

[0026] The load change rate correction factor F1 takes into account the impact of different load change rates on transient soot emissions. Because the load change will affect the actual air-fuel ratio, the uniformity of the mixture, and the uniformity of the intake air of each cylinder, which will greatly affect the adequacy of combustio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com