Short fiber reinforced composite material mechanical property prediction method based on CT scanning

A short fiber reinforced, composite material technology, applied in the field of materials, can solve the problems of mechanical properties prediction, no establishment of reactive composite materials, etc., to achieve the effects of improving mechanical properties, computing efficiency and computing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

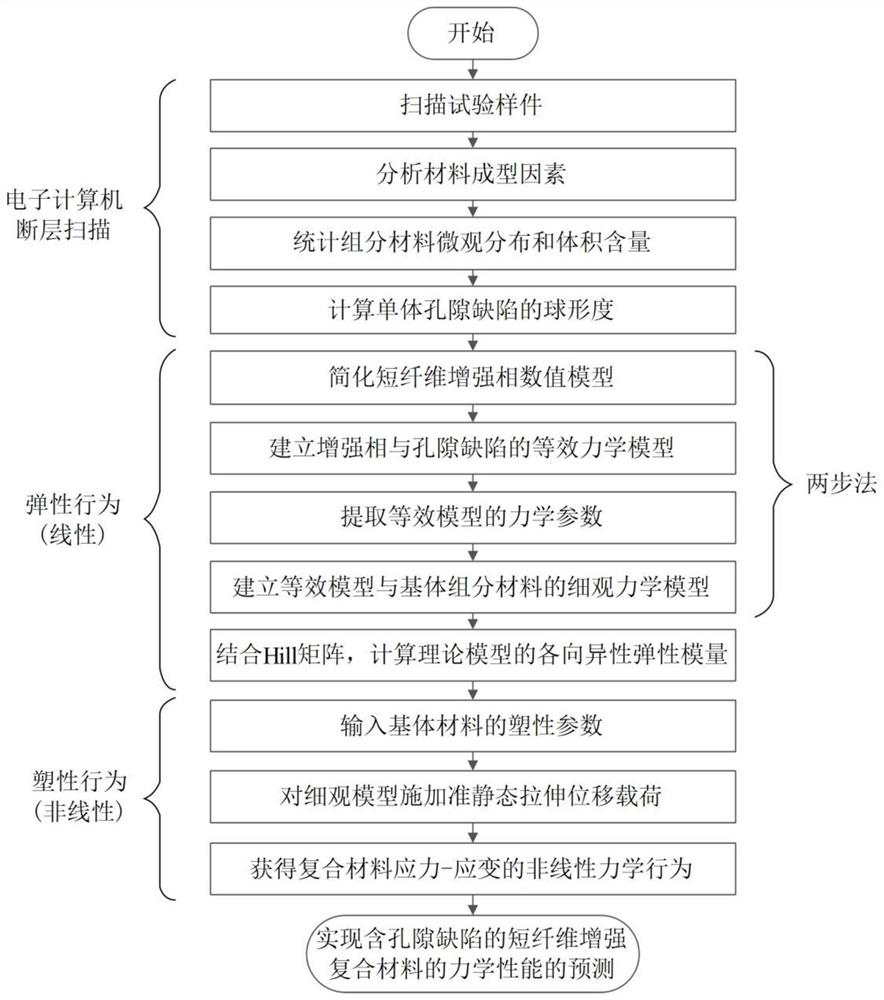

[0033] Below in conjunction with accompanying drawing, implementation process of the present invention is described in further detail:

[0034] refer to figure 1 , the implementation steps of the present invention are as follows:

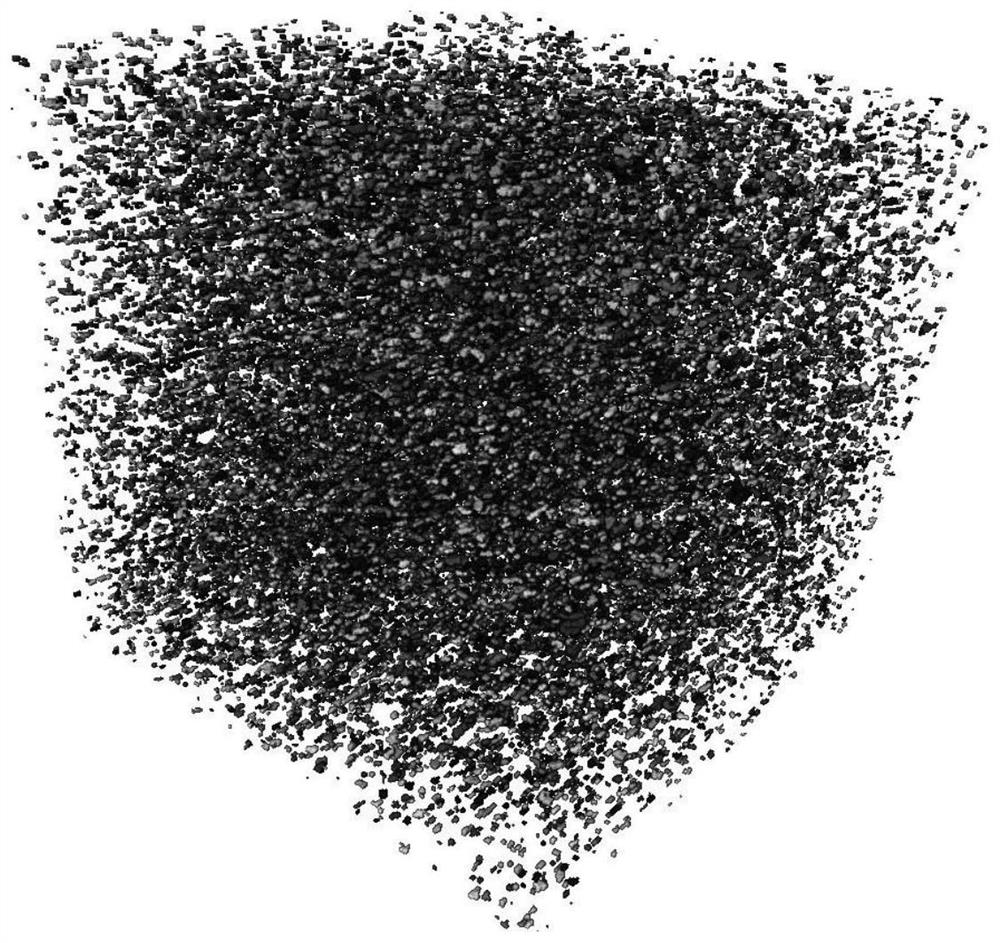

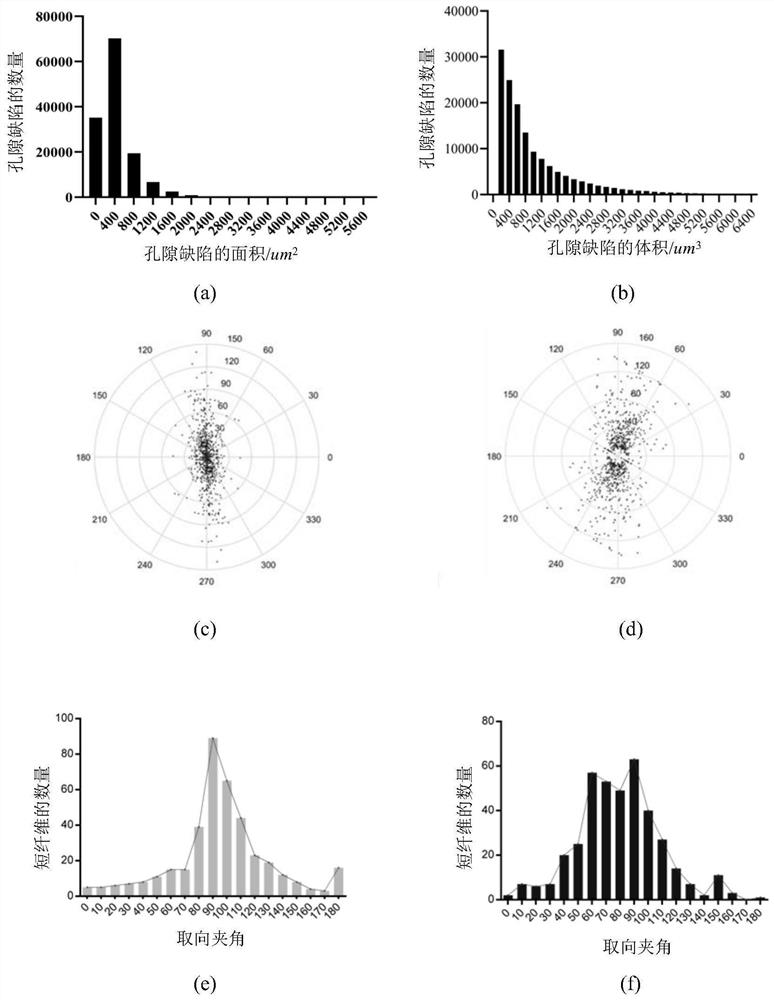

[0035] Step 1: Obtain the geometric characteristics of each component phase of the composite material through CT scanning technology, and perform segmentation and statistical processing to obtain the three-dimensional microscopic distribution and volume content of each component material.

[0036] 1.1) Based on the micron-level CT scanning technology, a 2mm*2mm*2mm CT scanning sample is cut from a 500mm*500mm*2.5mm custom board. The sample material used in this example is a short glass fiber-reinforced polyether ether ketone composite material PEEK / GL30 with a micron-sized mass content of 30%, and the material contains pore defects;

[0037] 1.2) Use Zeiss Xradia 520versa equipment to conduct CT scanning experiments on the sample materials, set th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com