Method and device for determining well cementation quality

A method and quality determination technology, applied in the field of determination of cementing quality, can solve the problem of low accuracy of cementing quality, achieve the effect of increasing reference factors and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0098] In order to make the purpose, technical solution and advantages of the present application clearer, the implementation manners of the present application will be further described in detail below in conjunction with the accompanying drawings.

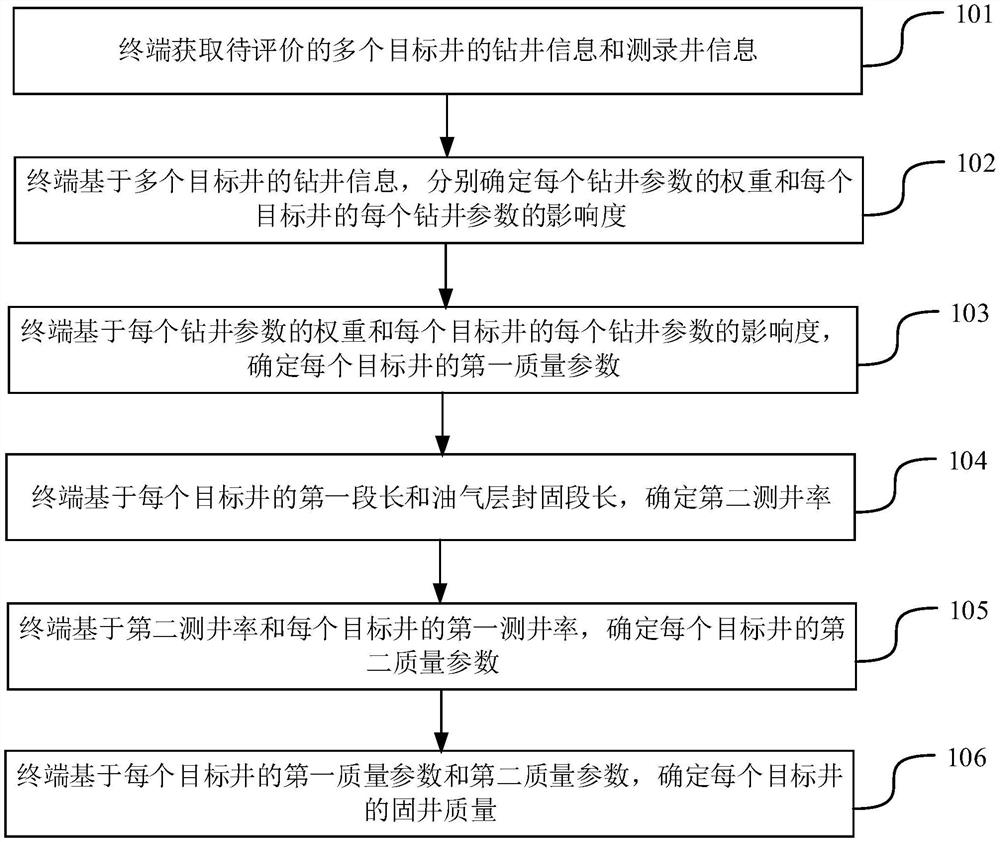

[0099] This embodiment provides a method for determining the cementing quality, see figure 1 , the method includes:

[0100] Step 101: The terminal acquires drilling information and logging information of multiple target wells to be evaluated.

[0101] Among them, the drilling information includes multiple drilling parameters. The multiple drilling parameters include the completion depth, the length of the oil and gas layer sealing section, the maximum inclination angle, the expansion rate of the well diameter, and the return height ratio. Deep proportions. The logging information includes the length of the first section and the first logging rate. The first section length is the section length of the target well section whose ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com