Anti-static heat dissipation device for electronic components

A technology for electronic components and heat sinks, applied in the field of electronic component protection, can solve problems such as easy damage, electronic components do not have heat dissipation and anti-static properties, etc., to avoid damage and eliminate electrostatic charges.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further explained below in conjunction with specific embodiments.

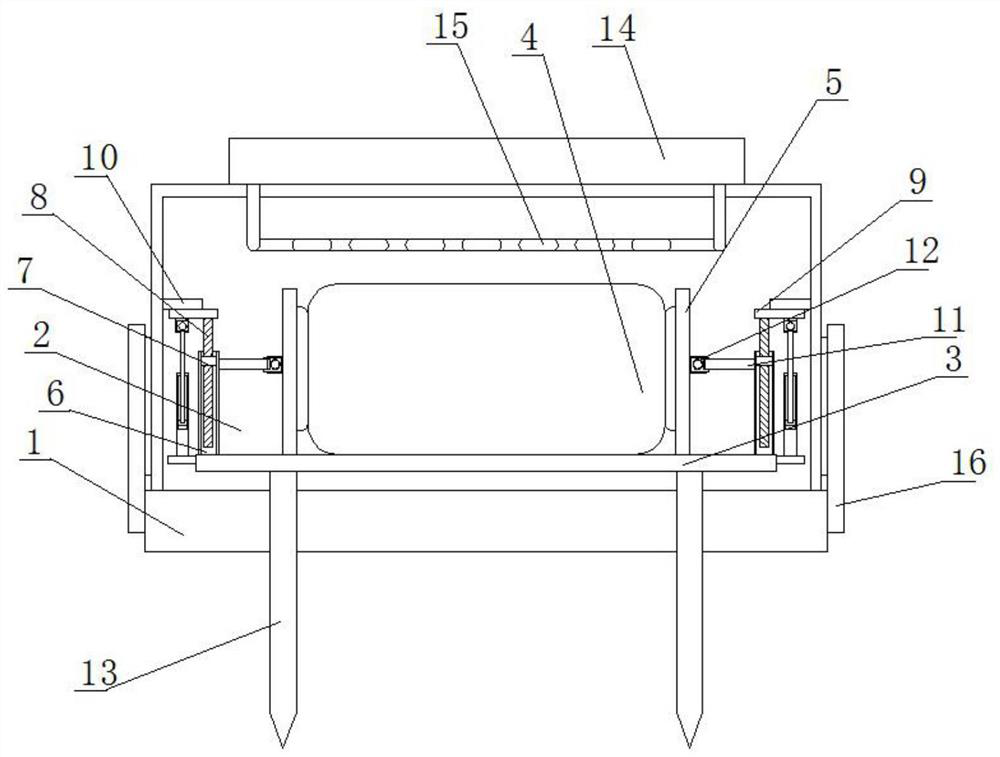

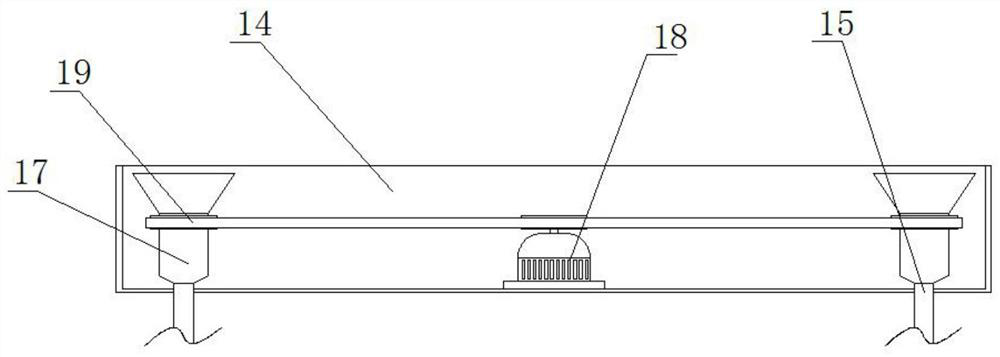

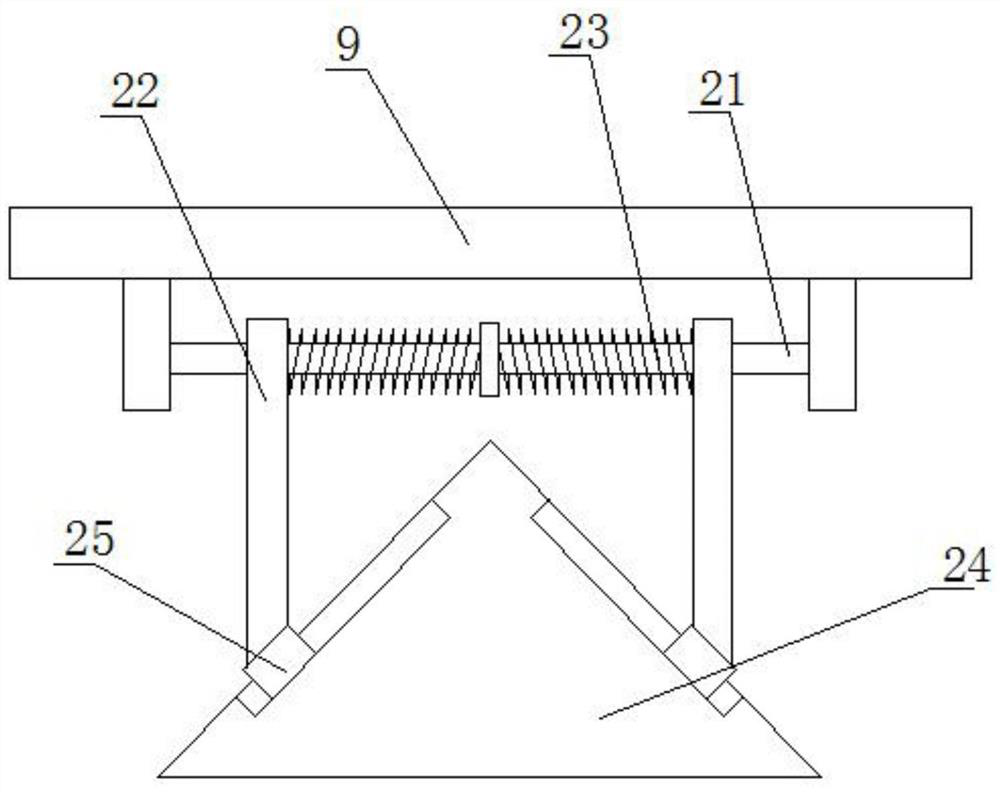

[0024] refer to Figure 1-5 In this embodiment, an anti-static cooling device for electronic components is proposed, which includes a base 1, a protective cover 2 is clamped on the top of the base 1, and two grounding rods 13 are symmetrically and fixedly installed on the base 1, and the two grounding rods The top of 13 is fixed and electrically installed with a grounding plate 3 located in the protective cover 2, and the top of the grounding plate 3 is provided with an electronic component 4, and the electronic component 4 is in electrical contact with the grounding plate 3, and the top of the grounding plate 3 slides symmetrically Two splints 5 are connected, and the two splints 5 are clamped with the electronic components 4, and the top of the ground plate 3 is connected with two rotating tubes 6 symmetrically and rotationally, and the two rotating tubes 6 are respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com