Cover plate, storage device with cover plate and kitchen equipment applying cover plate

A technology of kitchen equipment and cover plate, which is applied in the field of kitchen utensils, can solve the problems of inconvenient cleaning of the countertop, dust, debris falling under the countertop, etc., and achieve the effect of improving neatness and aesthetics, good sealing, and neat and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0056] The difference between Embodiment 2 and Embodiment 1 is that: a first sealing ring 21 is provided on the cover body 2 .

[0057] Such as Figure 8 As shown, the periphery of the cover body 2 is formed with a circle of downwardly extending steps 22, and the step surface 221 of the steps 22 is provided with a first sealing ring 21. When the cover body 2 is embedded in the through hole 51, The first sealing ring 21 abuts against the lower end surface of the table top 5 and surrounds the outer periphery of the through hole 51 to prevent water, oil, etc. 2 and the gap between the platform 5 drops into the first accommodating tank 1 .

[0058] In addition, the step 22 can also play a positioning role. For example, for the sake of appearance, when the cover body 2 is moved into the through hole 51, the upper end surface of the cover body 2 is flush with the upper end surface of the table 5, so the step is designed. The height of 22 can play the role of limiting the moving st...

Embodiment 3

[0060] Such as Figure 9 , 10 As shown, the difference between embodiment 3 and embodiment 2 is that the first accommodation groove 1 is not provided, and at this time the cover body 2 can still be embedded in the through hole 51 under the action of the drive assembly 4 (see Figure 9 ), or the cover plate body 2 is located below the table top 5 and at least partially deviates from the direct position of the through hole 51 (see Figure 10 ). This embodiment is more suitable for the following scenarios: in order to make full use of the space below the table top 5, some items, such as grain, oil, etc., will be placed under the table top 5, and the items will be picked and placed from the through hole 51 of the table top 5, but the through hole 51 will make Dust, debris, etc. fall into the bottom of the table top 5 from here, and the bottom of the table top 5 is not easy to clean, so a cover plate is set to solve this problem. Objects fall from the through hole 51 below the t...

Embodiment 4

[0062] Embodiment 4 is to protect a storage device with a cover plate without a table top 5. The storage device includes a second accommodating tank 7 with an open top. The structure of the cover plate is except for the arrangement of the second guide section and the sealing ring. Different, other structures of the cover plate can refer to embodiment 2, specifically as follows:

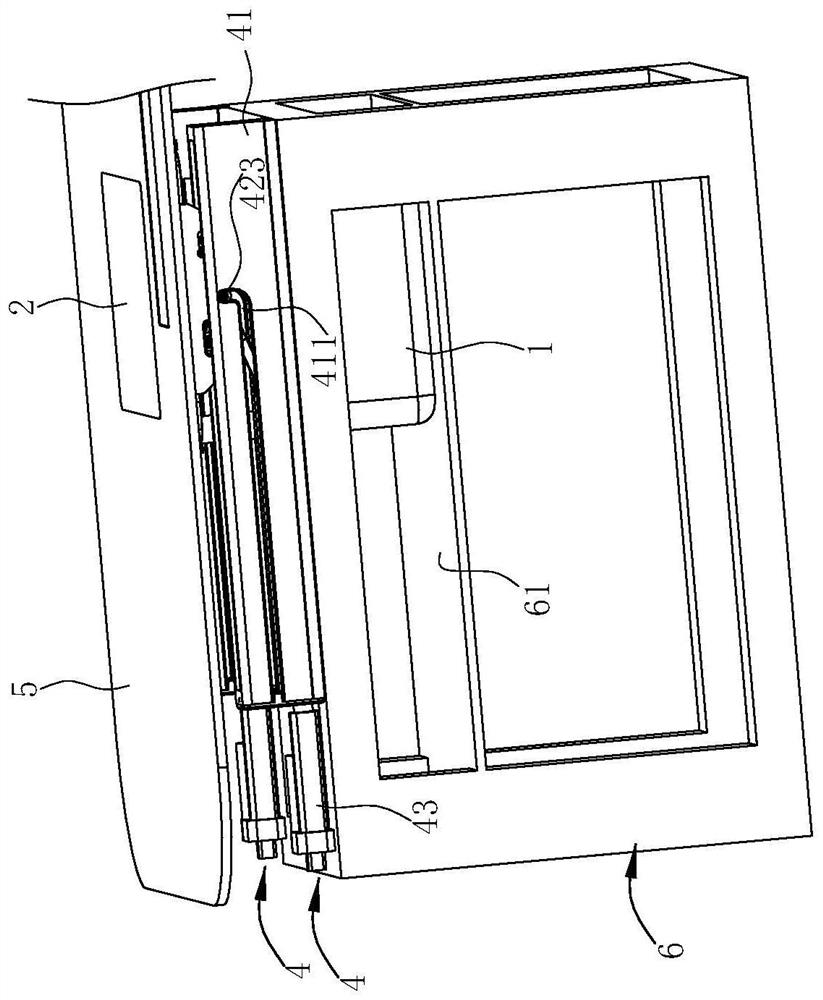

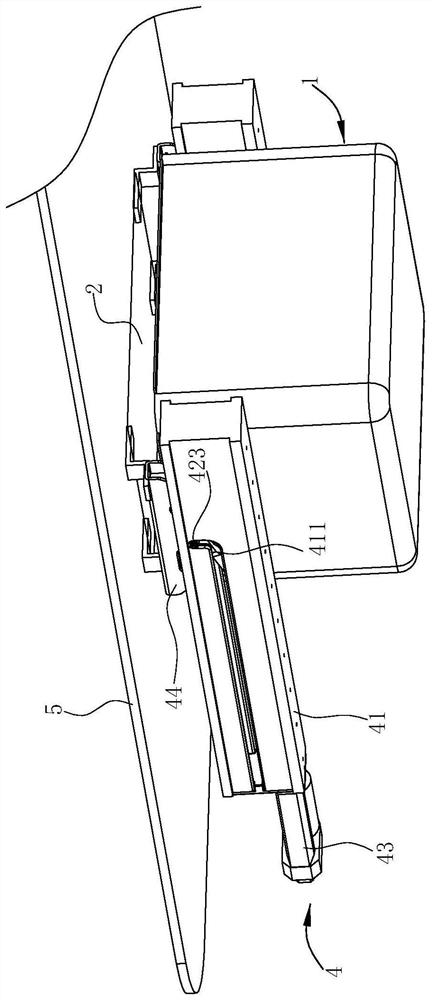

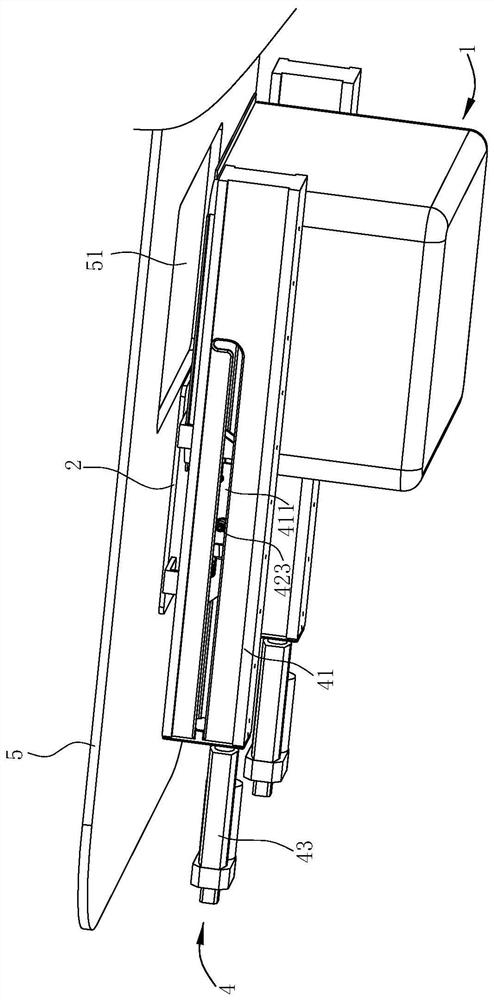

[0063] Such as Figures 11 to 14 As shown, the top of the second accommodating groove 7 is open, and the cover body 2 can close the notch of the second accommodating groove 7 or at least partially deviate from the position facing the notch of the second accommodating groove 7 . The slide rail 3 is located on one side of the second receiving slot 7 and extends along the horizontal direction, and the driving assembly 4 is used to drive the cover body 2 to translate or lift relative to the second receiving slot 7 .

[0064] Such as Figure 12 , 13 As shown, the driving assembly 4 includes a guide fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com