Multi-point clamping positioning device for constructional engineering material detection

A technology for construction engineering and positioning devices, which is applied in the direction of workpiece clamping devices and manufacturing tools, can solve the problems of inability to obtain effective positioning and reduced detection efficiency, and achieve the effects of being suitable for popularization and use, avoiding material waste, and improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

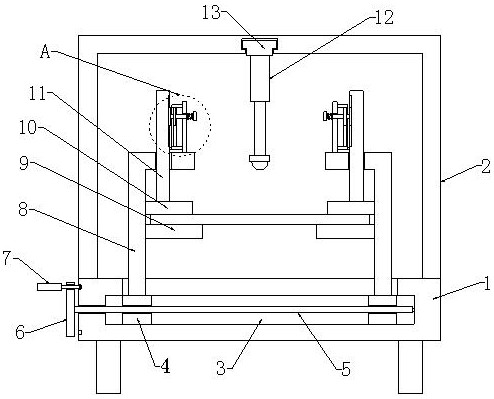

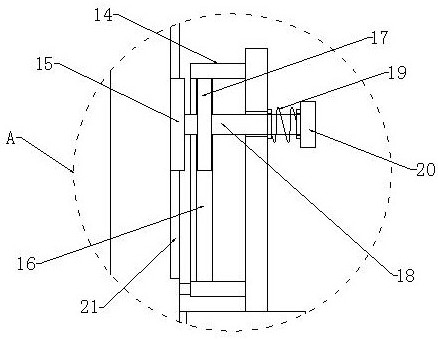

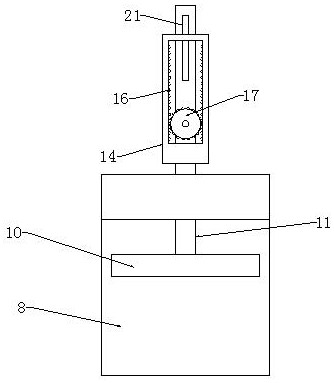

[0028] refer to Figure 1-5 , a multi-point clamping positioning device for construction materials detection, including a console 1, an inverted U-shaped bracket 2 is fixedly installed on the top of the console 1, and a chute is arranged on the bracket 2, and the chute slides inside A slide block 13 is installed, and the bottom end of the slide block 13 is fixedly connected with a cylinder 12, and the inside of the console 1 is slidably installed with a movable block 4, and the top of the movable block 4 is fixedly connected with a mounting frame 8, and the top end of the mounting frame 8 extends To the top of the operating table 1, and the mounting frame 8 is arranged in an L-shaped structure, the horizontal section of the mounting frame 8 slides through and is provided with a positioning plate 11, and the bottom end of the positioning plate 11 is fixedly connected with a pressing plate 10, and the mounting frame 8 The top of the horizontal section is fixedly connected with a...

Embodiment 2

[0033] refer to Figure 6 and 7, the present embodiment makes a change in the connection between the placement plate 9 and the mounting frame 8, so that the vertical section of the placement plate 9 and the mounting frame 8 is in a hinged form, the placement plate 9 is provided with a moving groove 28, and the inside of the moving groove 28 slides A clamping rod 25 is installed, and a positioning spring 26 is connected between the clamping rod 25 and the inwall of the moving groove 28, and the vertical section of the mounting frame 8 is fixedly connected with a fixed plate 23, and the fixed plate 23 is provided with a frame matching the clamping rod 25. The limit groove 24 of the fixed plate 23 is provided with two clamping grooves 27 with the same structure, the clamping groove 27 is matched with the clamp rod 25, the fixed plate 23 and the limiting groove 24 are all arranged in an arc structure, and the two clamping grooves 27 is located on the same side of the limiting gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com