A piston pin marking production line

A production line and piston pin technology, used in typewriters, printing devices, printing and other directions, can solve the problems of low work efficiency, occupying a lot of personnel and equipment, and occupying a large space, and achieve the effect of reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

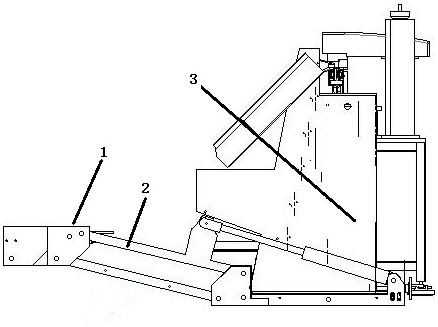

[0027] A piston pin marking production line, characterized in that the production line includes a feeding device, a lifting device, a vertical transfer device, a marking device, and a storage box, and the feeding device is arranged on the side of the lifting device, The feeding device includes a parallel arm and a flap controlled by an oil cylinder. The lower part of the parallel arm is fixed on the side of the lifting device. Under the control of the oil cylinder, it moves around the lifting device in a circular motion. plate, the flap makes a circular motion around the upper part of the parallel arm under the control of the oil cylinder;

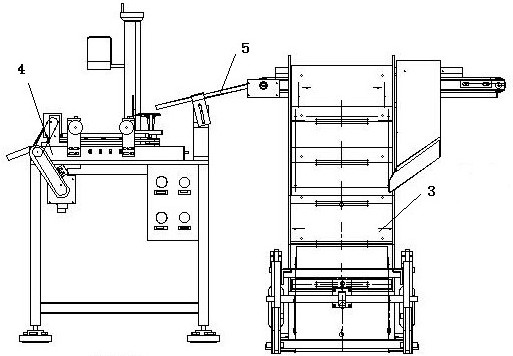

[0028] The hoisting device is configured as an entire row hoist, and a rubber band conveyor belt is arranged at the rear of the row hoist, and the end of the rubber band conveyor belt is connected to the erecting transfer device through a V-shaped slideway.

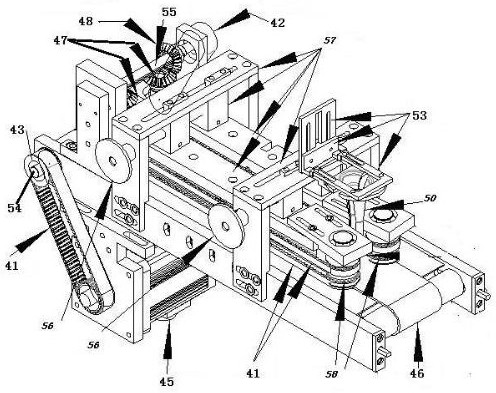

[0029] The vertical transfer device includes a funnel, a belt and a synchronous b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com