Automatic storing and taking system and storing and taking method

An access system and item technology, applied in the field of logistics and warehousing, can solve the problems of high cost of special shelves, limited application range, no automation, etc., and achieve the effect of high versatility, low cost, and firm clamping of items

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to better understand the technical content of the present invention, specific embodiments are given together with the accompanying drawings for description as follows.

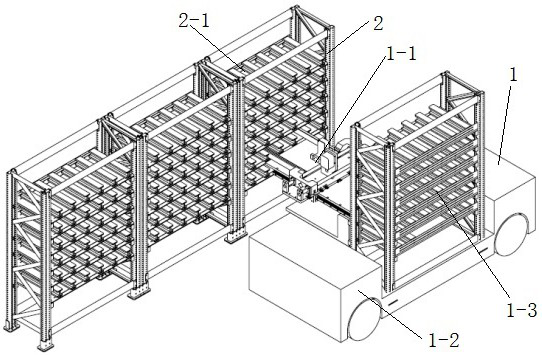

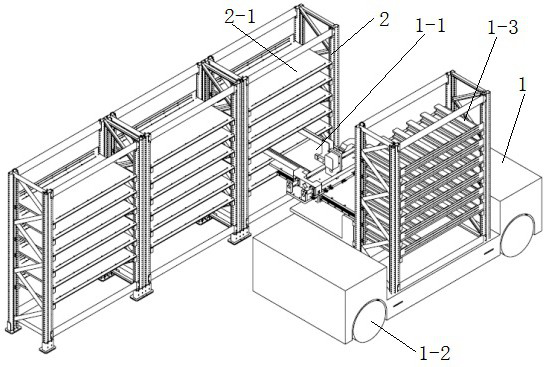

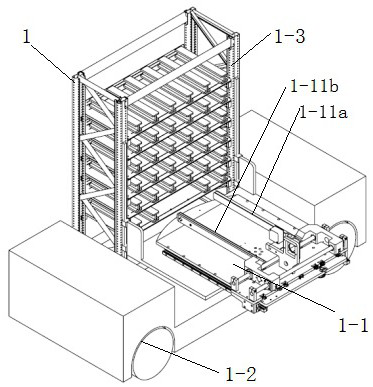

[0051] According to a preferred embodiment of the present invention, an automated access system is proposed, such as Figure 1 to Figure 6As shown, it includes a shelf 2 with multiple cargo lanes 2-1, at least one AGV trolley 1 and a control unit (not shown in the figure). Each cargo lane 2-1 has a unique number, and the control unit is provided with a storage module (not shown in the figure), which is used to record the cargo lane number, the specific location information corresponding to the cargo lane number, and the binding between the two It is also used to record the inventory information of cargo lane 2-1.

[0052] The control unit generates one or more task instructions according to the order requirements (a task instruction can be of the same item type or multiple item types, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com