Isobaric electric control mechanical filling valve

A filling valve and electronic control technology, applied in packaging, bottle filling, liquid bottling, etc., can solve the problems of waste of resources, short service life, easy damage of filling valve, etc., to eliminate liquid level deviation and prolong service life , the effect of avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

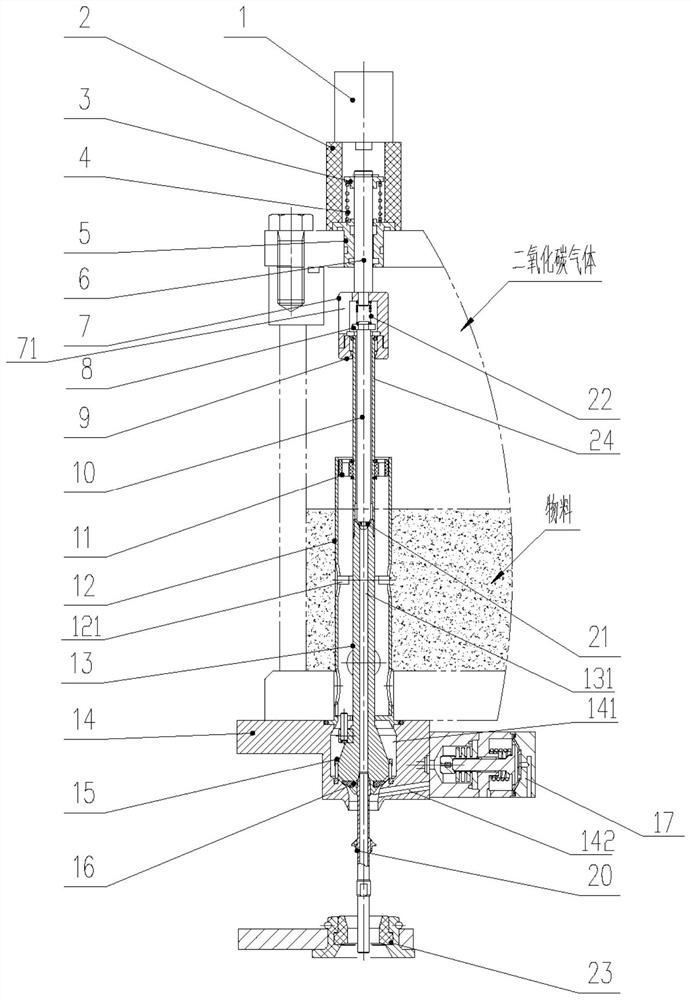

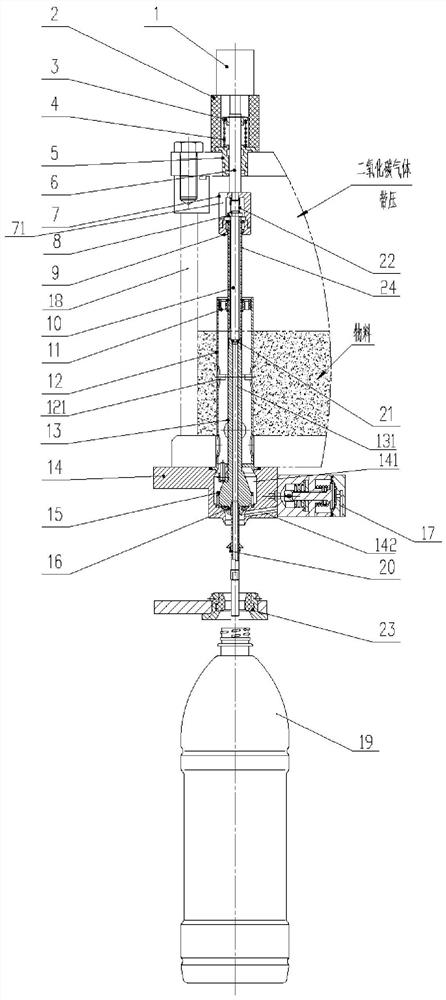

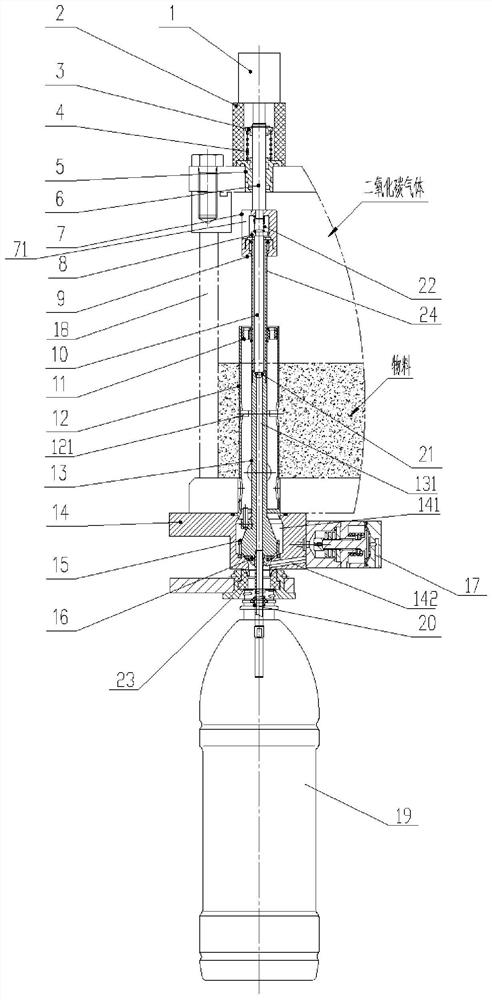

[0019] Such as Figure 1~2 As shown, an isobaric electronically controlled mechanical filling valve includes a valve seat 14, a valve body 12 vertically fixed on the top of the valve seat 14, and a valve core 13 that is vertically interspersed in the valve body 12 and can slide up and down; The top of the valve seat 14 is provided with a valve cavity 141, and a comb-shaped sleeve 15 is embedded in the valve cavity 141. The lower end of the valve core 13 is movably inserted in the comb-shaped sleeve 15 and cooperates with the lower opening of the valve cavity 141. There are vent holes 131 vertically distributed in 13, and a plurality of liquid inlet holes 121 are opened on the outer wall of the valve body 12; it also includes a guide block 11, a sleeve 24, a gasket 16, a gas return pipe 20 and a diaphragm valve 17; The sleeve 24 is vertically and concentrically fixed on the upper end of the valve core 13, the guide block 11 is sheathed and fixed on the upper end of the valve co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com