A kind of solvent-free temperature-resistant epoxy phenolic anticorrosion coating and preparation method thereof

A technology of epoxy phenolic and anti-corrosion coatings, which is applied in the field of coatings and can solve problems such as low coating efficiency, high VOC, and large environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

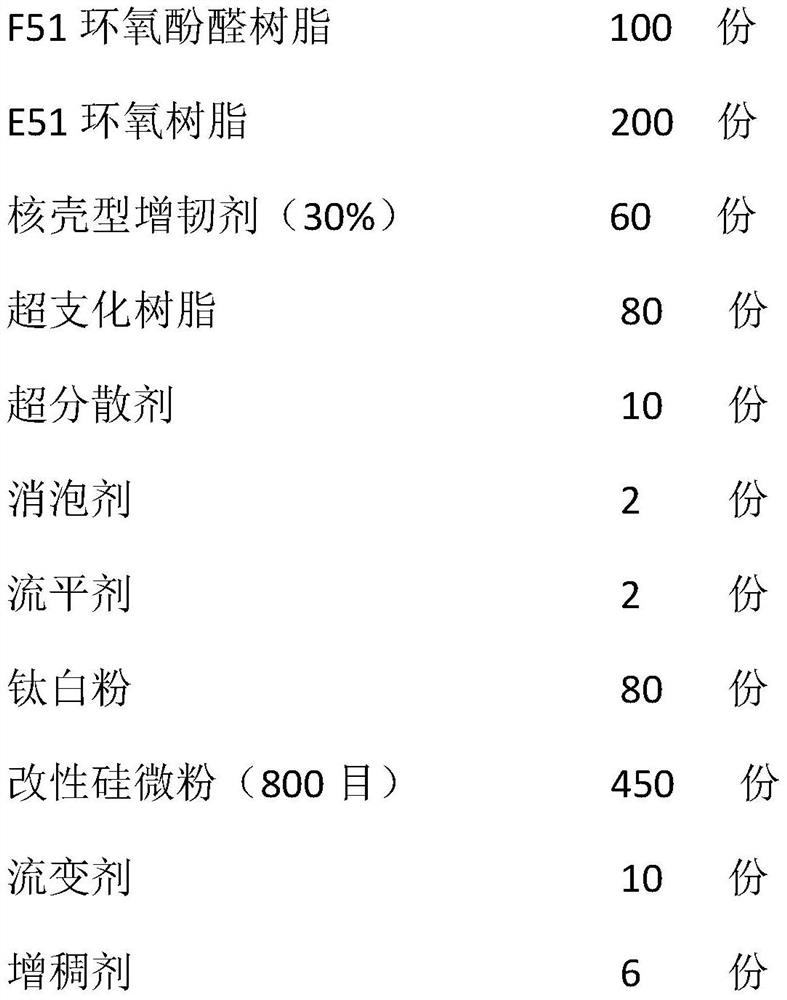

Embodiment 1

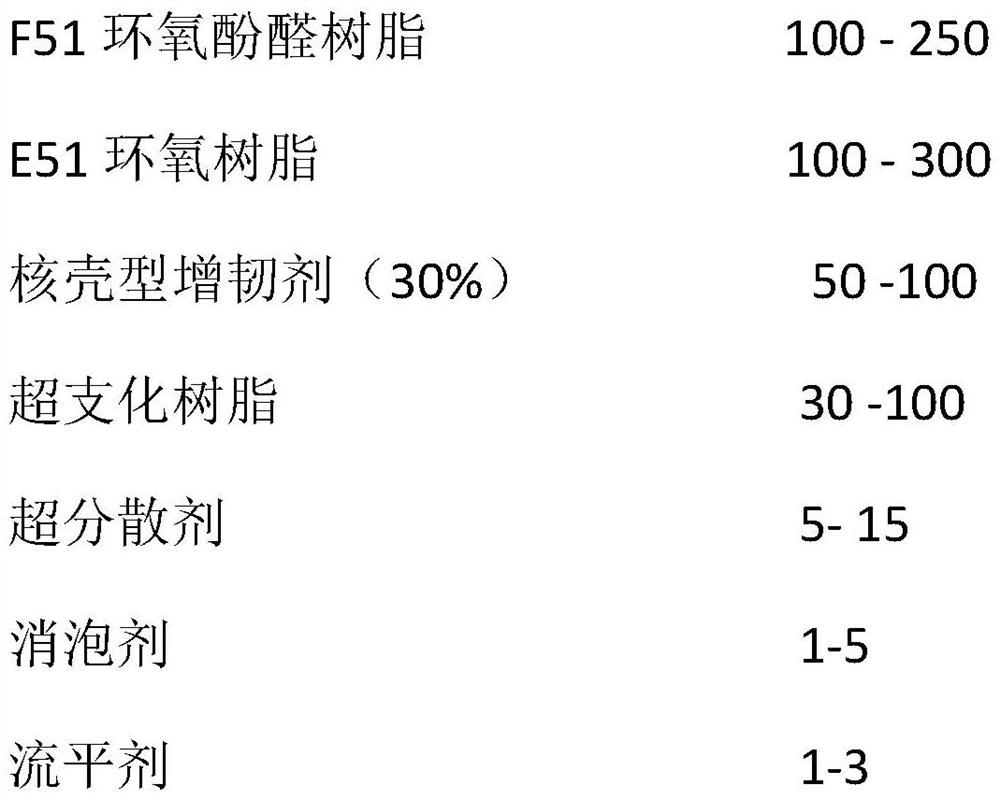

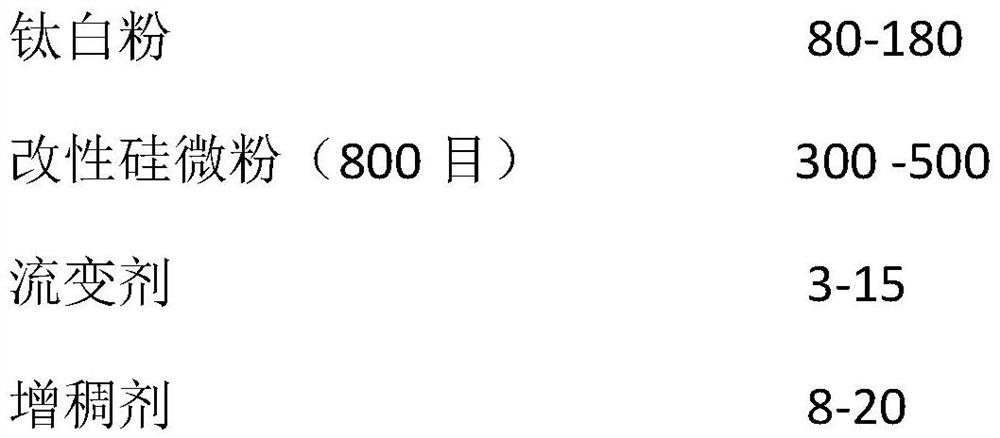

[0040] The composition of component A according to the mass fraction is:

[0041]

[0042] The preparation method of modified silica micropowder:

[0043] After diluting propyltrimethoxysilane with ethanol to a mass concentration of 30%, spray it into the 800-mesh silicon micropowder that has been in the high-speed stirring device (the amount of silane is 1.0% of the silicon micropowder), and stir for 20 minutes. Drying at 110°C to remove solvent and moisture to obtain modified silicon micropowder with oil absorption ≤18g / 100g.

[0044] Preparation of Component A

[0045] F51 epoxy phenolic resin needs to be baked and heated to 50 ℃ in advance. Add E51 epoxy resin, core-shell toughening agent (30%), hyperbranched resin, hyperdispersant, defoamer, and leveling agent into the paint mixing kettle. After stirring evenly, add titanium dioxide and modified silicon powder. Stir at high speed for 30 minutes, fineness ≤ 75um, add preheated F51 epoxy phenolic resin, then add rheol...

Embodiment 2

[0058]The composition of component A according to the mass fraction is:

[0059]

[0060] The preparation methods of the modified silicon micropowder and the A component are the same as those in Example 1.

[0061] The composition of component B according to the mass fraction is:

[0062] Modified aromatic amine 350 parts

[0063] Modified fatty amine Ancamide 2766 650 parts

[0064] The modified aromatic amine is composed of:

[0065] E51 100 servings

[0066] DDM 35 servings

[0067] Ruetasolv DI 10 servings

[0068] The preparation methods of DDM-modified aromatic amine prepolymer and component B are the same as those in Example 1.

[0069] A:B=4:1.

Embodiment 3

[0071] The composition of component A according to the mass fraction is:

[0072]

[0073] The preparation methods of the modified silicon micropowder and the A component are the same as those in Example 1.

[0074] The composition of component B according to the mass fraction is:

[0075] Modified aromatic amine 250 parts

[0076] Modified fatty amine Ancamide 2766 750 parts

[0077] The modified aromatic amine is composed of:

[0078] E51 100 servings

[0079] 40 servings of DDM

[0080] Ruetasolv DI 20 copies

[0081] The preparation methods of DDM-modified aromatic amine prepolymer and component B are the same as those in Example 1.

[0082] A:B=4:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com