Solvent-free temperature-resistant epoxy phenolic aldehyde anticorrosive coating and preparation method thereof

An epoxy phenolic and anti-corrosion coating technology, applied in the coating field, can solve the problems of low volume solid content, low coating efficiency, large environmental pollution, etc., and achieve enhanced temperature resistance, convenient coating construction, temperature resistance and chemical resistance. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

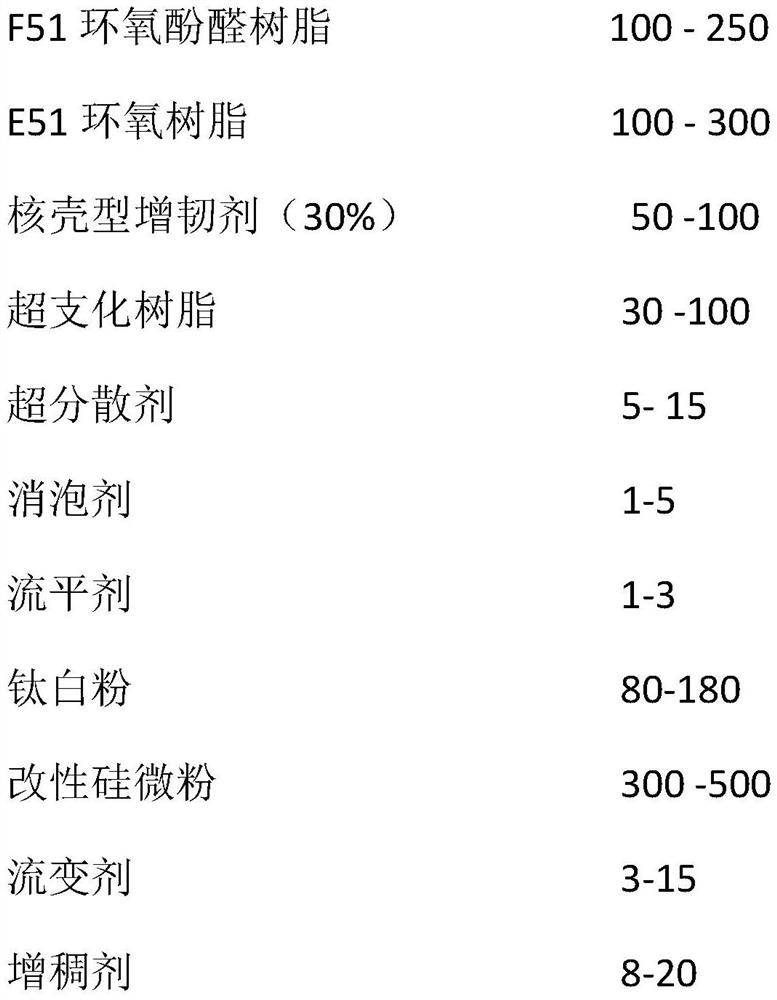

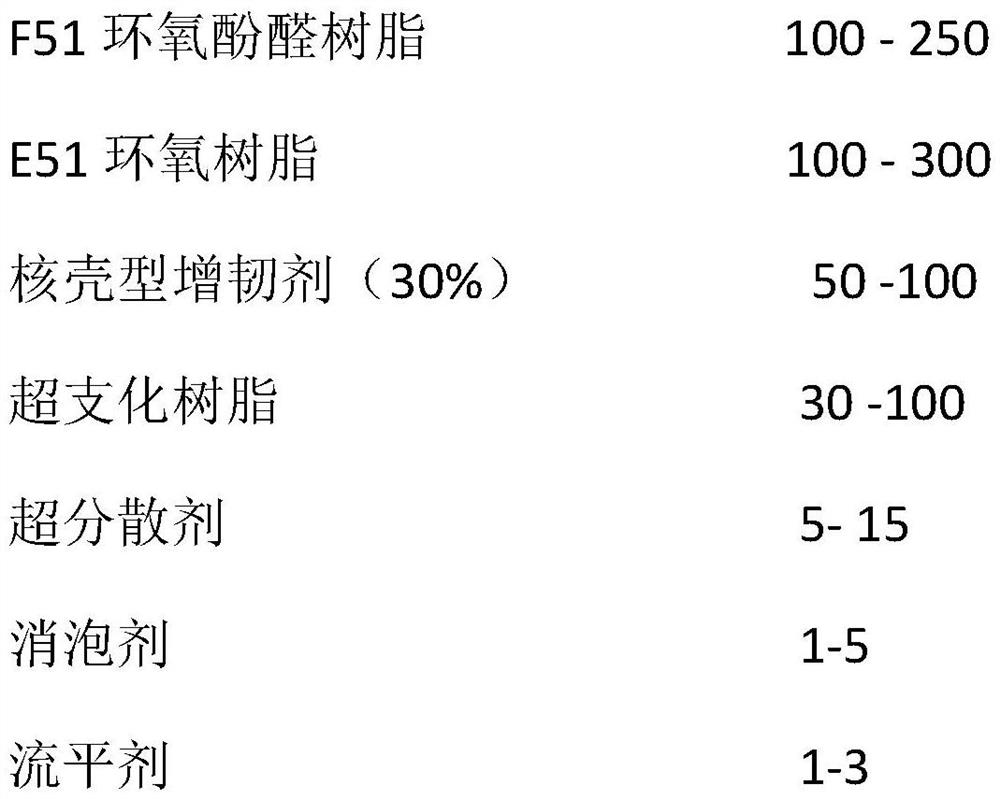

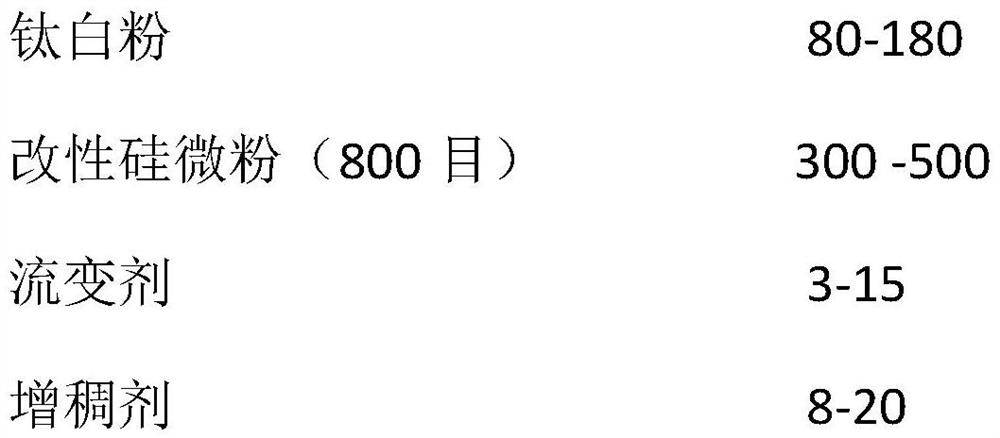

[0040] The composition of A component according to the mass parts is:

[0041]

[0042] The preparation method of modified silica powder:

[0043] Propyltrimethoxysilane is diluted to mass concentration 30% with ethanol, sprays and joins in the 800 order silicon micropowder body (silane consumption is 1.0% of silicon micropowder) in the high-speed stirring equipment, after stirring for 20 minutes, in Dry at 110°C to remove the solvent and moisture to obtain modified silicon micropowder with oil absorption ≤ 18g / 100g.

[0044] Preparation of A component

[0045] F51 epoxy phenolic resin needs to be baked and heated to 50°C in advance for use. Add E51 epoxy resin, core-shell toughening agent (30%), hyperbranched resin, hyperdispersant, defoamer, leveling agent into the paint kettle, stir evenly, add titanium dioxide and modified silica powder, Stir at high speed for 30 minutes, fineness ≤ 75um, add preheated F51 epoxy phenolic resin, then add rheological agent and thickene...

Embodiment 2

[0058]The composition of A component according to the mass parts is:

[0059]

[0060] The preparation method of modified silica powder and component A is the same as in Example 1.

[0061] The composition of B component according to the mass parts is:

[0062] Modified aromatic amine 350 parts

[0063] Modified fatty amine Ancamide 2766 650 parts

[0064] Modified aromatic amine is composed of according to the mass parts:

[0065] E51 100 copies

[0066] DDM 35 copies

[0067] Ruetasolv DI 10 servings

[0068] The preparation method of DDM modified aromatic amine prepolymer and component B is the same as in Example 1.

[0069] A:B=4:1.

Embodiment 3

[0071] The composition of A component according to the mass parts is:

[0072]

[0073] The preparation method of modified silica powder and component A is the same as in Example 1.

[0074] The composition of B component according to the mass parts is:

[0075] Modified aromatic amine 250 parts

[0076] Modified fatty amine Ancamide 2766 750 parts

[0077] Modified aromatic amine is composed of according to the mass parts:

[0078] E51 100 copies

[0079] DDM 40 copies

[0080] Ruetasolv DI 20 servings

[0081] The preparation method of DDM modified aromatic amine prepolymer and component B is the same as in Example 1.

[0082] A:B=4:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com