Low-viscosity high-solid acrylic polyurethane coating and preparation method thereof

An acrylic polyurethane, high-solid technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve problems such as high VOC emissions, coating anti-corrosion failure, topcoat orange streaks, etc., to reduce VOC emissions, protect the environment, and reduce The effect of viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Embodiments of the present invention are as follows:

[0011] 1. Preparation of acrylic modified resin: take 45 parts of methyl acrylate and 50 parts of methacrylate by weight and heat them to 130°C for copolymerization, then add 3 parts of 2,4 dimethoxysilane and 0.7 parts of dibutyl potassium to promote agent, stirred at low speed for 20 minutes, cooled to 120 degrees, distilled and dehydrated, and cooled for later use.

[0012] 2. Coating preparation. Physically mix 69 parts of acrylic modified resin, 30 parts of rutile titanium dioxide (R902) and 0.2 part of dispersant (BYK-110) by weight, and disperse to 15 microns after grinding, and stir at a low speed. , Slowly add 1 part of leveling agent (EFKH-3777), 0.2 parts of defoamer (BYK052), 1 part of surfactant (3M), 1 part of anti-settling agent (Bontong27), 10 parts of curing agent (3390), and complete Then continue to stir for 30 minutes and cool to obtain the finished product.

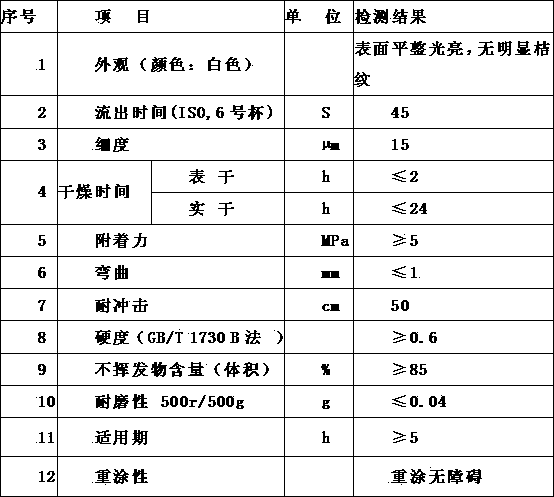

[0013] 3. Performance testing:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com