Tubular connecting piece, heat-preservation outer formwork cast-in-place concrete wall and wall construction method

A technology for concrete walls and connectors, which is applied in the direction of walls, building components, buildings, etc., can solve the problems of lack of thermal insulation external formwork support and positioning functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

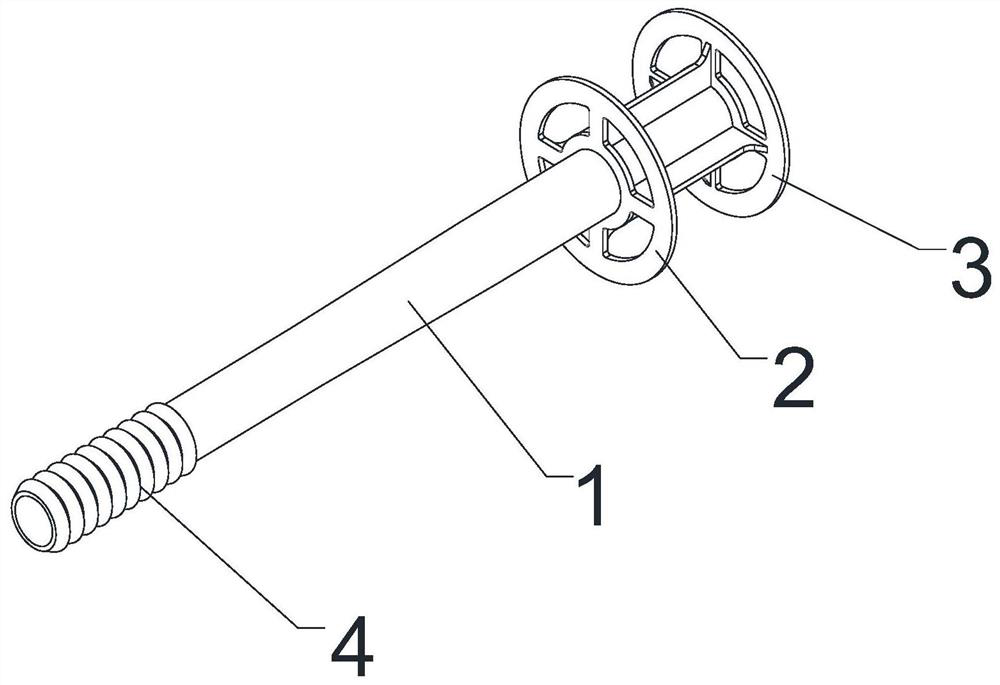

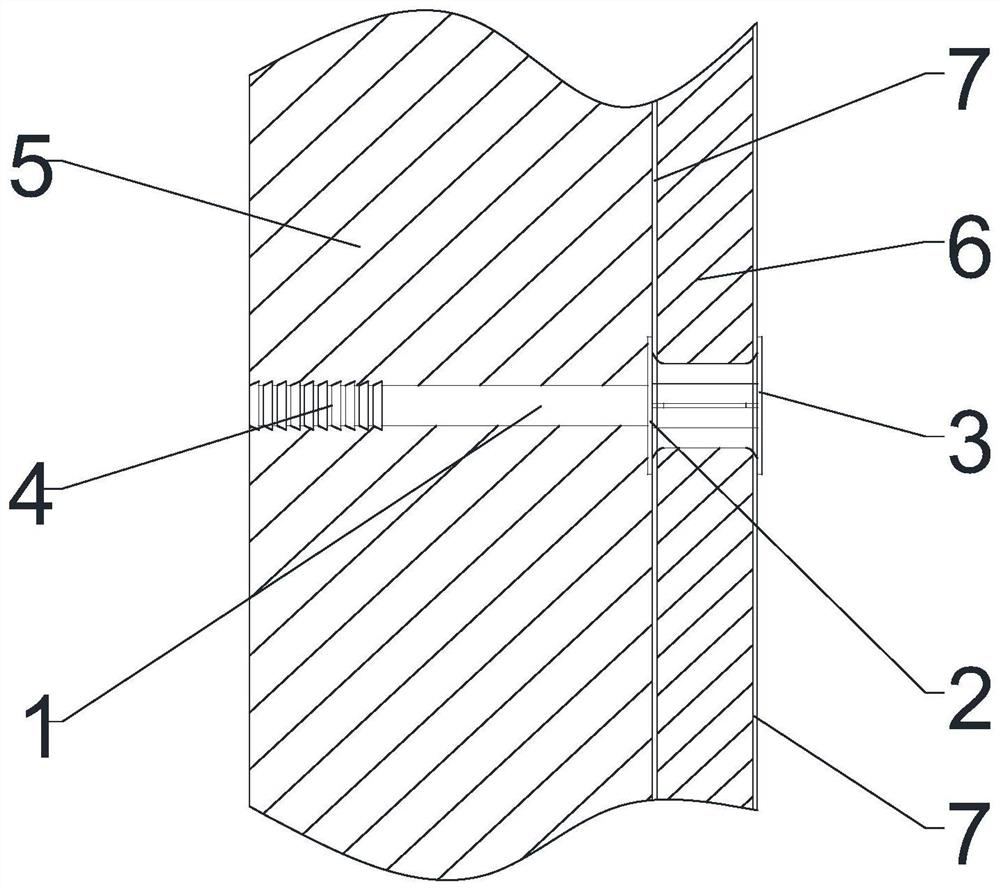

[0036] Such as figure 1 As shown, the tubular connector includes a tube body 1, the axial channel of the tube body 1 runs through the tube body 1 to form openings at both ends of the tube body 1, and the outer wall of the tube body 1 is provided with a first limiting piece 2 and a second limiting piece. The positioning piece 3 and the second limiting piece 3 are located at one end of the tube body 1 . When the tubular connector of the present invention is in use, the first limiting piece 2 and the second limiting piece 3 are located on both sides of the thermal insulation outer formwork 6 to realize the positioning of the thermal insulation outer formwork 6, and one end of the pipe body 1 abuts against the inner formwork , to realize the support of the inner formwork, and after tightening the inner formwork and the heat preservation outer formwork 6 by the pulling bolts, the fixing of the inner formwork and the heat preservation outer formwork 6 is realized. The second limiti...

Embodiment 2

[0046] The difference between this embodiment and embodiment 1 is that the first limiting piece 2 is fixedly connected or integrally formed with the tube body 1 , and the second limiting piece 3 is detachably connected with the tube body 1 . After the pipe body 1 passes through the thermal insulation outer formwork 6, the second limiting piece 3 is installed on the pipe body 1, and the second limiting piece 3 and the tubular body 1 are detachably connected to facilitate the assembly of the tubular connector and the thermal insulation outer formwork 6. Threads are provided on the outer wall of the pipe body 1, and the first limiting piece 2 is threadedly connected with the pipe body 1; The body 1 is detachably connected; or the outer wall of the tube body 1 is provided with a barb structure, and the first limiting piece 2 is connected with the tube body 1 through the barb structure.

[0047] The wall construction method comprises the following steps:

[0048] Step 1, opening a...

Embodiment 3

[0054] The difference between this embodiment and embodiment 1 is that both the first limiting piece 2 and the second limiting piece 3 are detachably connected to the tube body 1 .

[0055] The wall construction method comprises the following steps:

[0056] Step 1, opening a through hole on the heat preservation outer formwork 6, and then standing the heat preservation outer formwork 6 on the outside of the reinforcement frame;

[0057] Step 2, remove the first limiting piece 2 / second limiting piece 3, pass the tube body 1 through the through hole, and then install the first limiting piece 2 / second limiting piece 3 on the tube body 1, Make the first spacer 2 and the second spacer 3 lean against the thermal insulation outer template 6;

[0058] Step 3, supporting the inner formwork, passing the tension bolts through the inner formwork and the pipe body 1, and tightening the tension bolts;

[0059] Step 4, pouring concrete between the inner formwork and the thermal insulation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com