Test platform for simulating uniformly distributed load of pipeline in deepwater environment

A test platform and uniform load technology, which is applied in the testing of mechanical components, testing of machine/structural components, and the use of stable tension/compression to test the strength of materials. Guarantee, size effect and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific structure and implementation process of this solution will be described in detail below through specific embodiments and accompanying drawings.

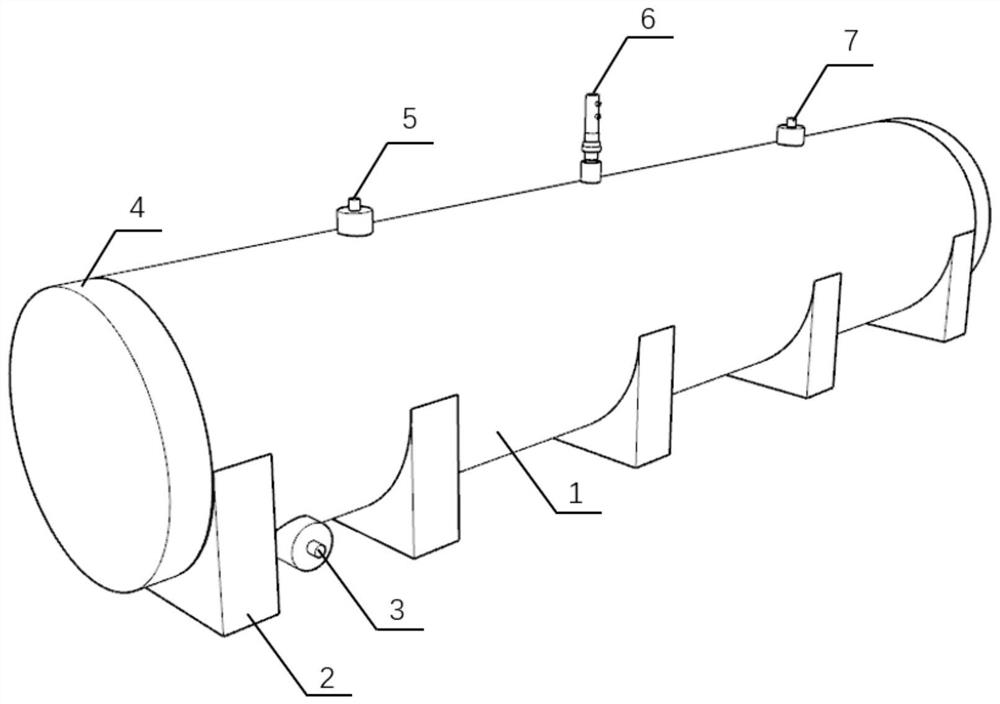

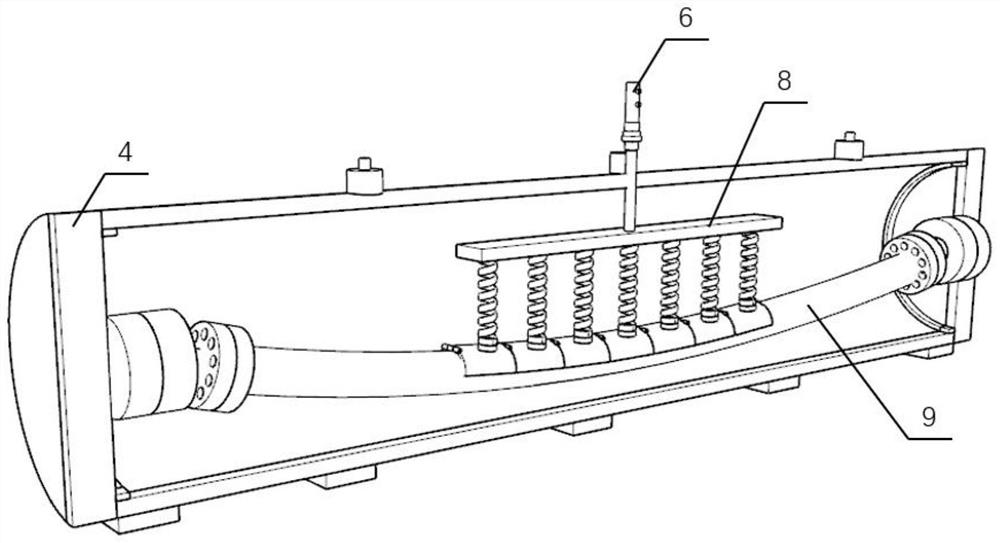

[0019] Such as figure 1 , 2 As shown, in one embodiment of the present invention, a test platform for simulating the uniform load of pipelines in a deep-water environment is disclosed, including a hollow hyperbaric cabin 1, which can be cylindrical and placed horizontally. The two ends of the hyperbaric cabin 1 are equipped with sealed movable hatches 4, through which the interior of the hyperbaric cabin 1 can be maintained and the test pipe fittings 9 can be installed, and the upper part of the hyperbaric cabin 1 is provided with a water inlet valve 5 and Exhaust valve 7, drain valve 3 is installed at the bottom.

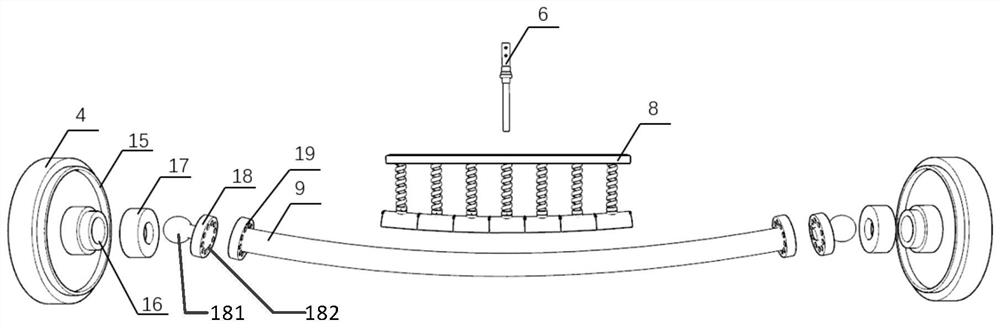

[0020] A test pipe fitting 9 and a load loading device 8 are installed in the hyperbaric cabin 1 .

[0021] The test pipe fitting 9 is a cutout section of the actual pipeline, and its two ends are f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com