Forming method for asymmetric pentagonal thin-wall cold-bent steel pipe with sharp corner

A forming method and asymmetric technology, applied in the field of cold forming, can solve the problems of high defective rate, difficult finishing forming, unstable welding quality, etc., and achieve the effect of easy export, stable extrusion welding, and ensuring smoothness and smoothness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to better understand the present invention, the invention will be described in detail below in conjunction with specific examples.

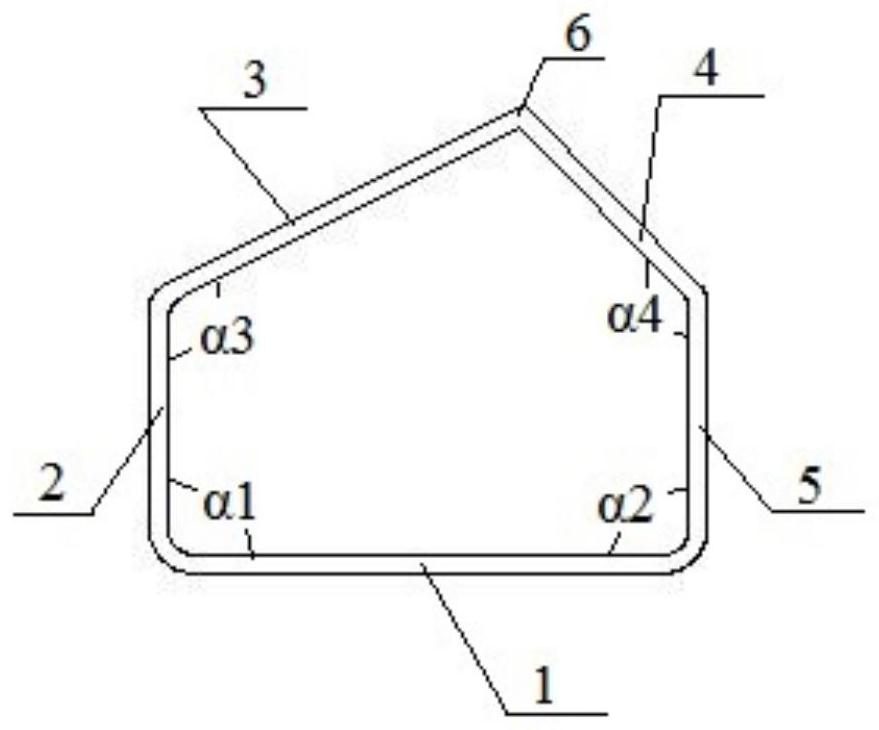

[0034] In this embodiment, the formed pipe (asymmetrical pentagonal thin-walled cold-formed steel pipe with sharp corners) is surrounded by a bottom edge 1, an outer waist edge 2, an outer welding edge 3, an inner welding edge 4, and an inner waist edge 5. Symmetrical pentagon shape, and the angle α1 between the bottom edge 1 and the outer waist edge 2 is 90°, the angle α2 between the bottom edge 1 and the inner waist edge 5 is 90°, and the angle between the outer waist edge 2 and the outer welding edge 3 α3 is 116.7° and the angle α4 between the inner waist edge 5 and the inner welding edge 4 is 135.7°, the outer welding edge 3 and the inner welding edge 4 are welded to form a sharp angle 6, and the center line O-O of the formed tube passes through the sharp angle 6 And the line segment perpendicular to the bottom edge 1 of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com