A mold slider release mechanism

A technology of mold sliders and sliders, which is applied in the field of injection molds, can solve the problems of not being able to meet production needs and low mold opening efficiency, and achieve the effect of improving mold opening efficiency and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described below in conjunction with accompanying drawing.

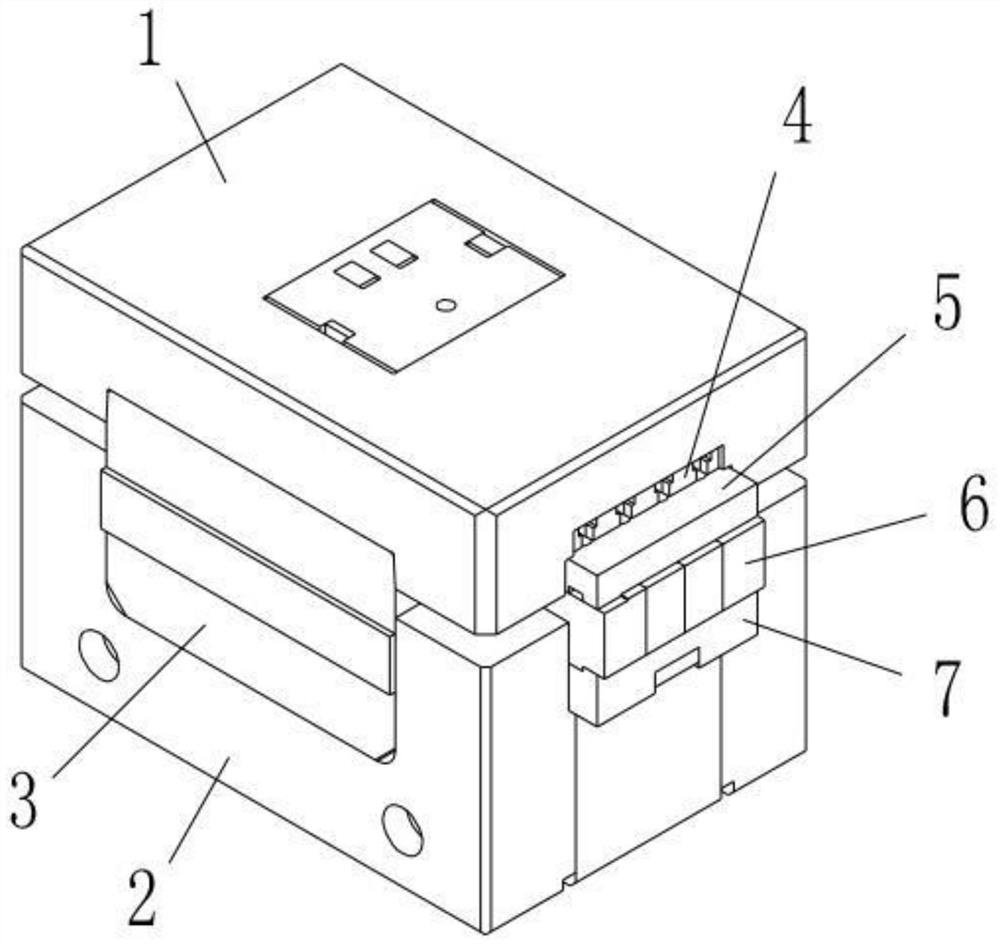

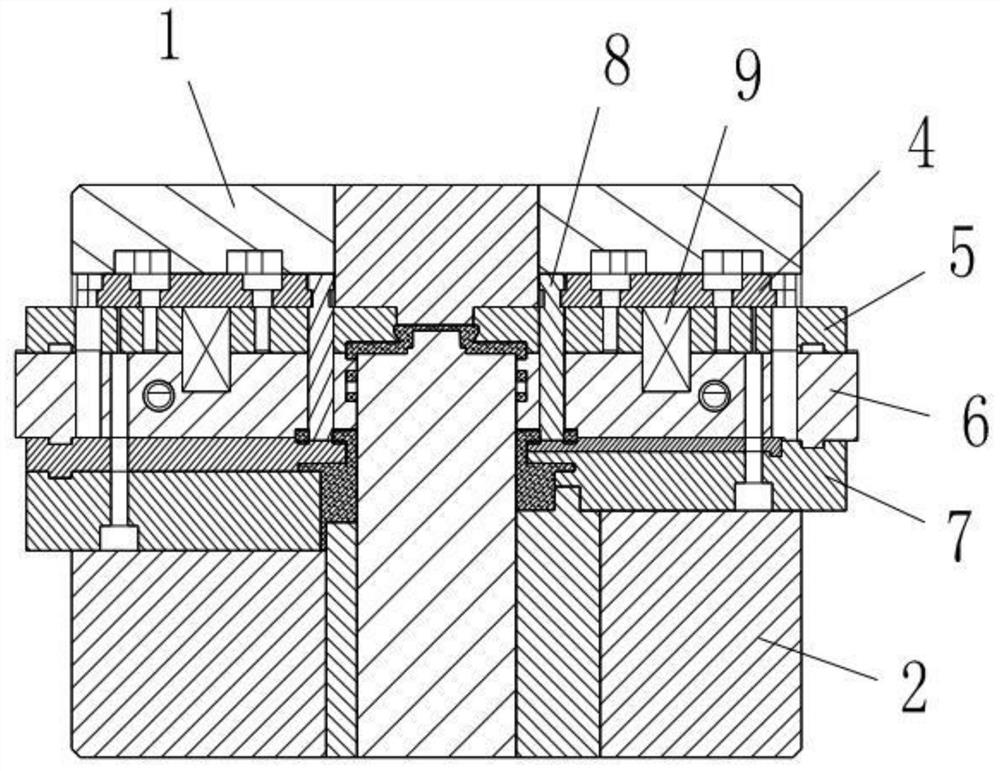

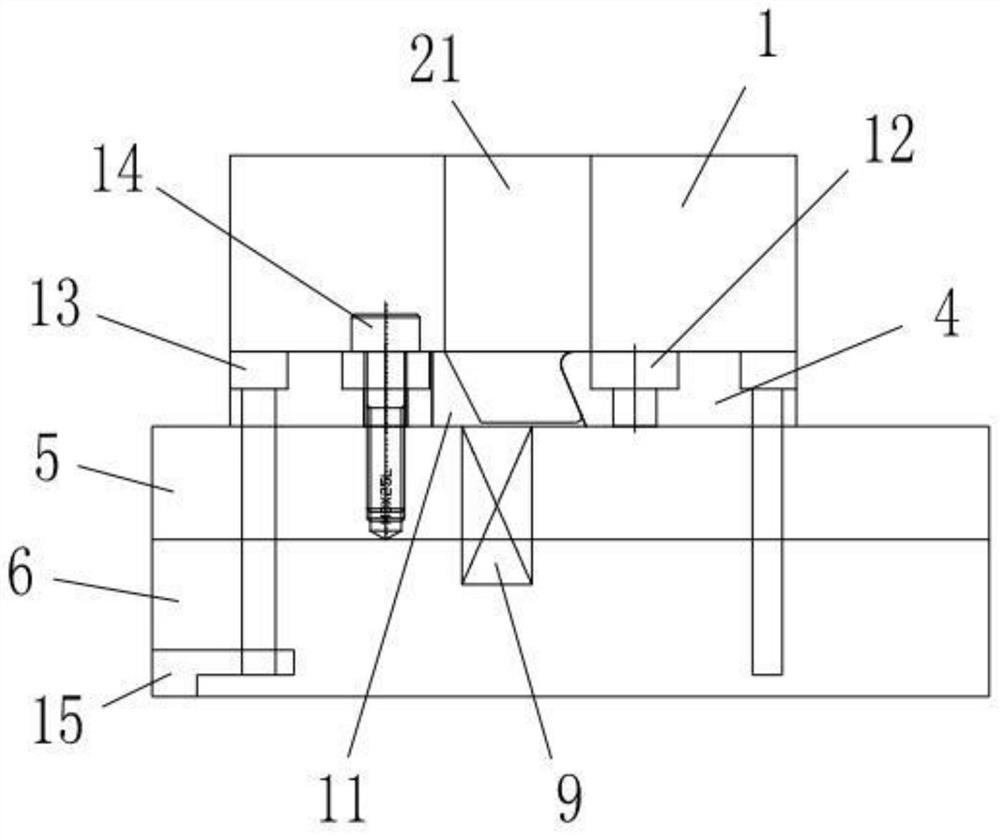

[0019] as attached Figure 1-4 As shown, a mold slider unlocking mechanism described in the present invention includes an upper mold core 1, a lower mold core 2 and a slider demoulding assembly, and an injection molding mold is arranged between the upper mold core 1 and the lower mold core 2. Cavity, the slide block demoulding assembly is set between the upper mold core 1 and the lower mold core 2; a set of slide block demoulding components are respectively arranged on the left and right sides of the upper mold core 1 and the lower mold core 2, and the upper mold core Side mold cores 3 are also arranged on the front and rear sides of core 1 and lower mold core 2 .

[0020] Each set of slider demoulding assembly includes a movable plate 4, a backing plate 5, a slider 6, an insertion rod 8 and an elastic ejection part 9, and the movable plate 4 and the slider 6 are respectively arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com