Maintainable tensioning device for engineering machinery crawler belt

A technology for construction machinery and tensioning devices, which is applied to tracked vehicles, motor vehicles, transportation and packaging, etc., can solve problems such as sealing failure of tensioning devices, corrosion of internal tie rods, damage to bushings, etc., and achieves good maintainability and guaranteed reliability. Excellent detachability and friction resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

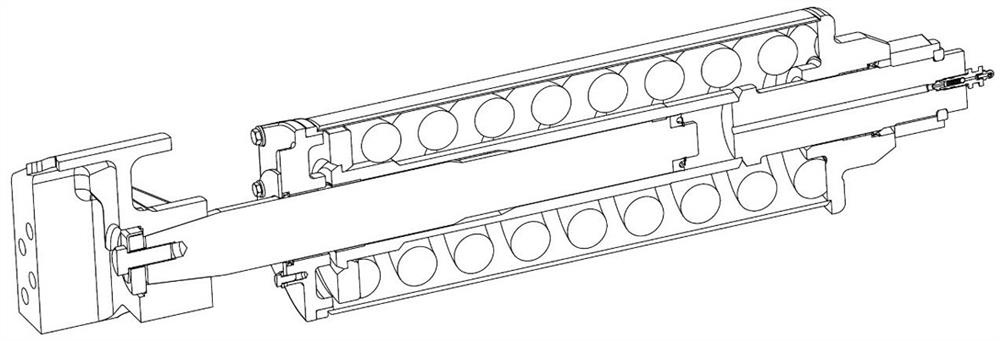

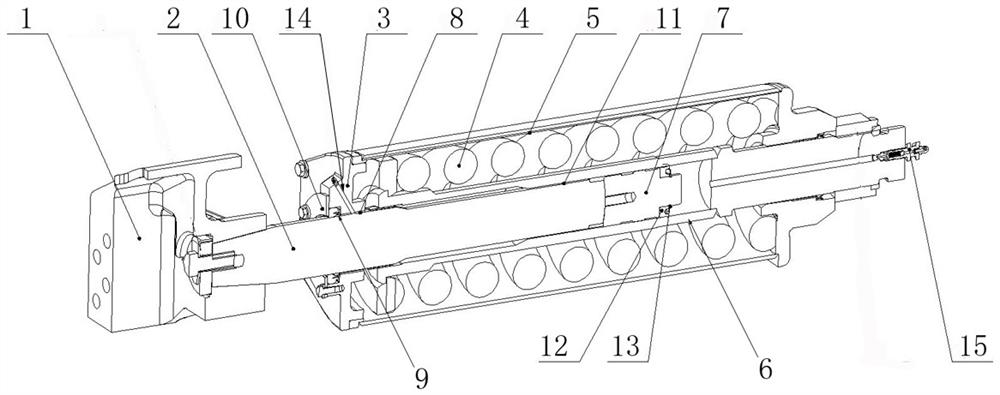

[0022] In order to enable those skilled in the art to better understand the technical solution of the present invention, the following in conjunction with the attached figure 2 - attached Figure 7 And the specific embodiment will further illustrate the present invention.

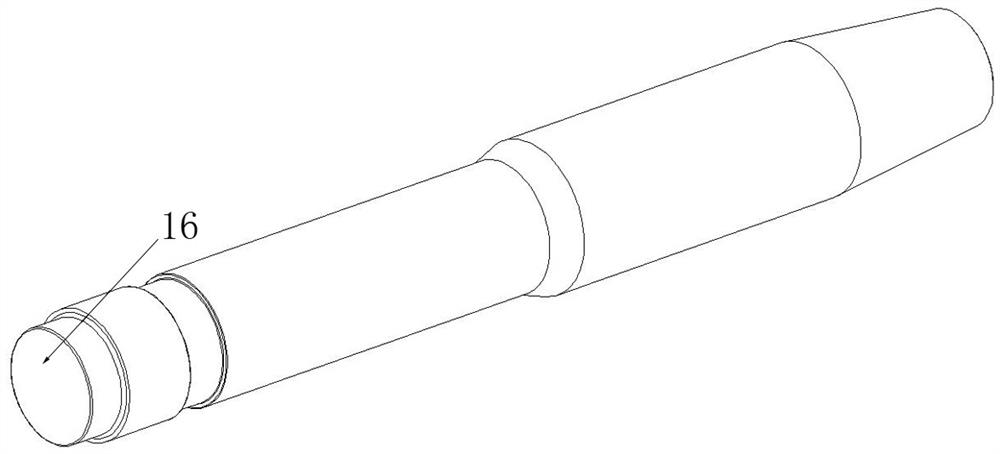

[0023] as attached figure 2 As shown, a maintainable tensioning device for engineering machinery crawlers includes a bracket 1, a connecting rod 2, an end cover 3, a spring 4, a spring box 5, an oil cylinder 6 and a piston 7, and the spring 4 is arranged on In the spring box 5, the oil cylinder 6 is arranged inside the spring 4, an oil injector 15 is arranged at one end of the oil cylinder 6, the piston 7 is arranged in the oil cylinder 6, and one end of the connecting rod 2 is connected to the piston 7. connection, the other end of the connecting rod 2 is connected to the bracket 1 through bolts, the end cover 3 is set at the outlet where the connecting rod 2 protrudes from the spring box 5, and the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com