Inspection door assembly of circular silo

A technology for inspecting doors and silos, applied in packaging, construction, underwater structures, etc., can solve the problems of limiting the opening angle of the door panel, inconvenient operation, time-consuming and laborious, etc., and achieve the effect of tight closing and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the drawings and embodiments, but it is not used as a basis for any limitation on the invention.

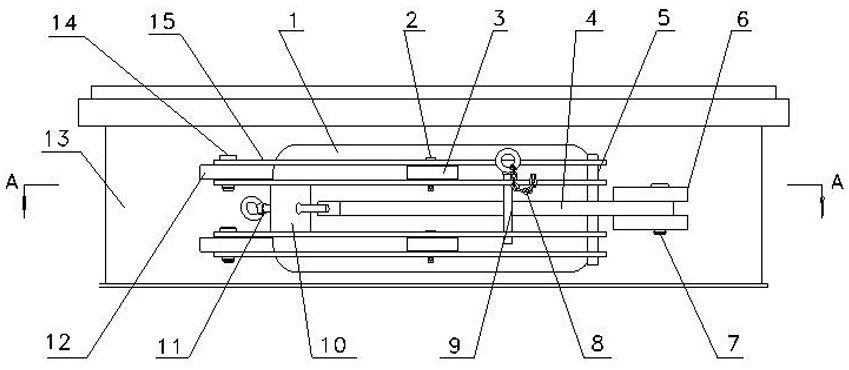

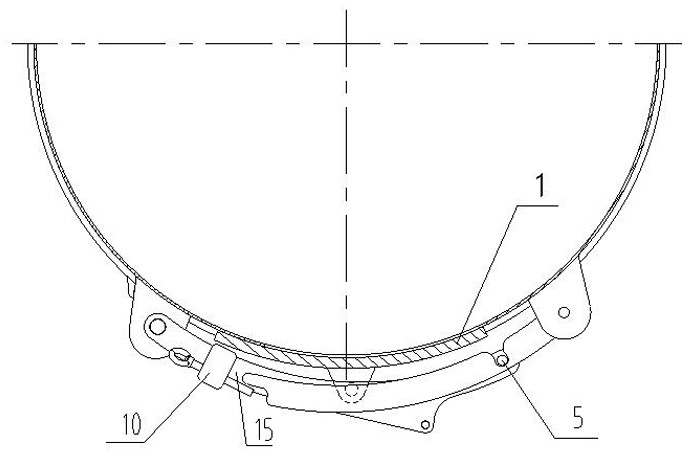

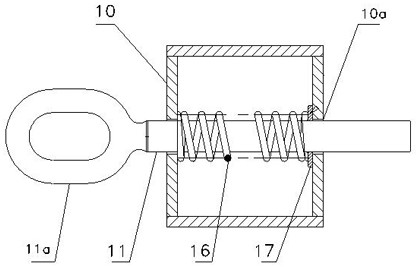

[0026] As shown in the figure, an inspection door assembly for a circular silo includes an arc-shaped door panel 1, an arc-shaped rotating bracket for installing the door panel 1, and an arc for pressing the door panel 1 against the inspection port 13a of the silo. shaped compression rod 4, and a locking pin for compressing and locking the compression rod 4.

[0027] The arc of the door panel 1 is consistent with the arc around the silo inspection port 13a. One end of the rotating bracket is hinged on the silo 13 at the side of the silo inspection port 13a. The arc-shaped convex surface is correspondingly installed, and the pressing rod 4 is opposite to the rotating bracket, hinged on the silo 13 at the position on the other side of the silo inspection port 13a, and the locking pin is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com