A detection system for wire rope broken strands and job hopping

A detection system and steel wire rope technology, applied in the field of elevators, can solve problems such as the collision between the trigger and the emergency stop switch, and achieve the effects of avoiding collisions, prolonging the service life, and accurate detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, creative features, goals and functions achieved by the present invention clearer and easier to understand, the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments:

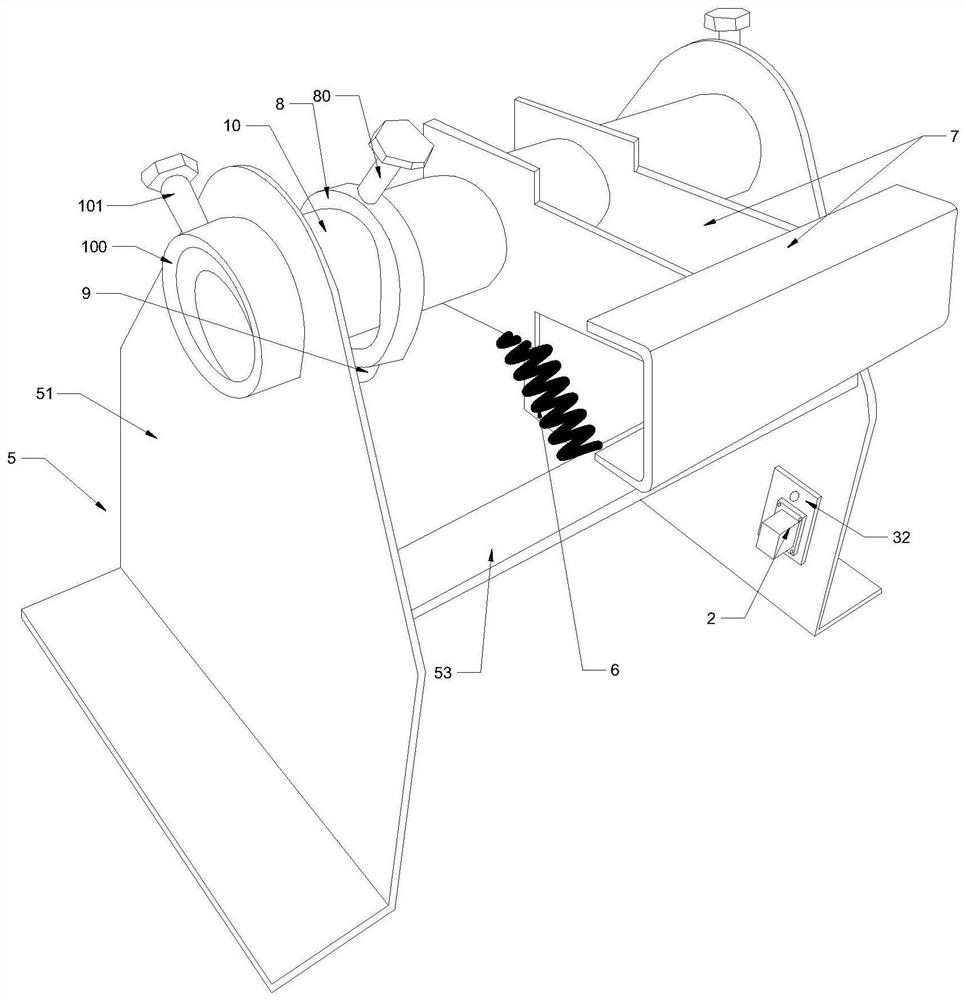

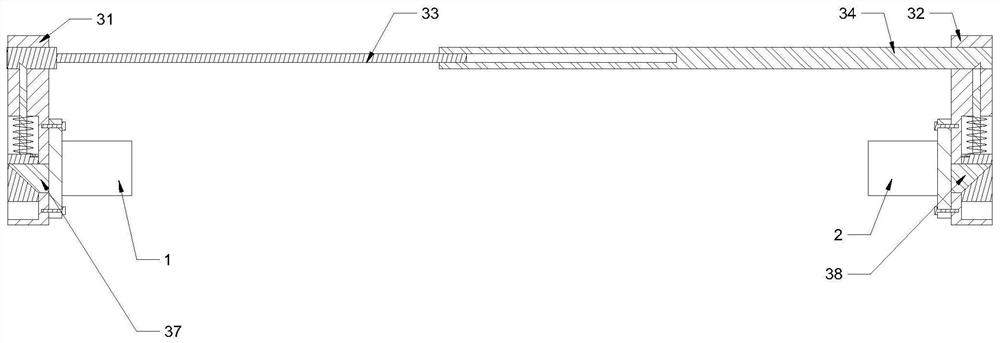

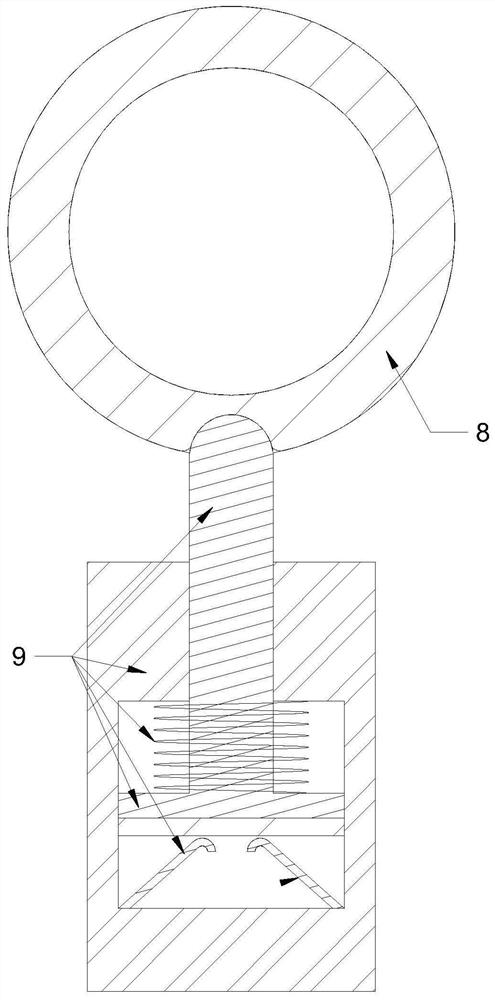

[0023] Such as Figure 1 to Figure 4 As shown, the present invention proposes a steel wire rope 4 broken strand detection system, including: a mechanical detection device and an optical detection device, and the mechanical detection device includes: a mounting base 5, an elastic member 6, a detection arm 7, and a detection ring 8 And the self-resetting switch 9, the mounting seat 5 is used to be installed on the vertical beam of the elevator and is positioned beside the wire rope 4 guide wheels, the mounting seat 5 is equipped with a rotatable detection arm 7, and the detection arm 7 is used as a steel wire rope at one end away from the mounting seat 5. 4 When a strand is broken or job hopping is in c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com