Deep hole grinding and cleaning device

A cleaning device and deep hole technology, applied in the direction of grinding drive device, cleaning method and tools, cleaning method using tools, etc., can solve the problem that deep holes cannot be ground and cleaned, and achieve simple structure, good cleaning effect, adaptable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

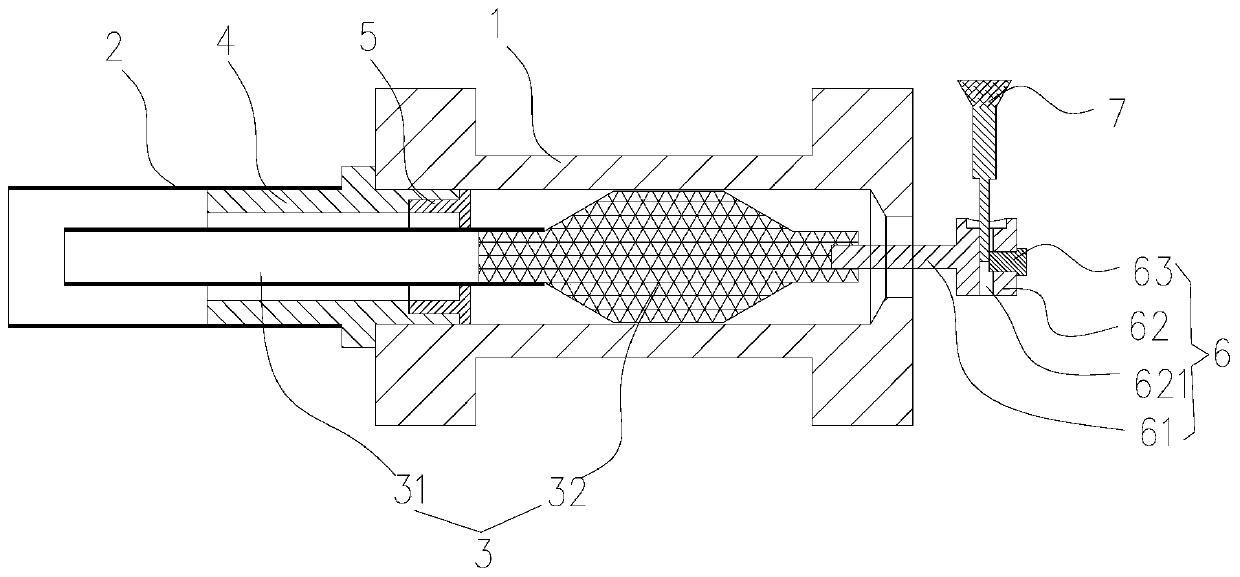

[0034] like figure 1 As shown, in the present embodiment, the deep hole grinding and cleaning device includes a power rotating part, a support body 1, a hand-held part 2, a grinding part or a cleaning part, and the support body 1 is fixedly connected with one end of the hand-held part 2, and the inside of the support body 1 It is a cavity, one end of the power rotating part is installed in the cavity, and the other end drives and connects the grinding or cleaning part. When grinding or cleaning, the grinding or cleaning part rotates with the length of the grinding or cleaning part as the radius.

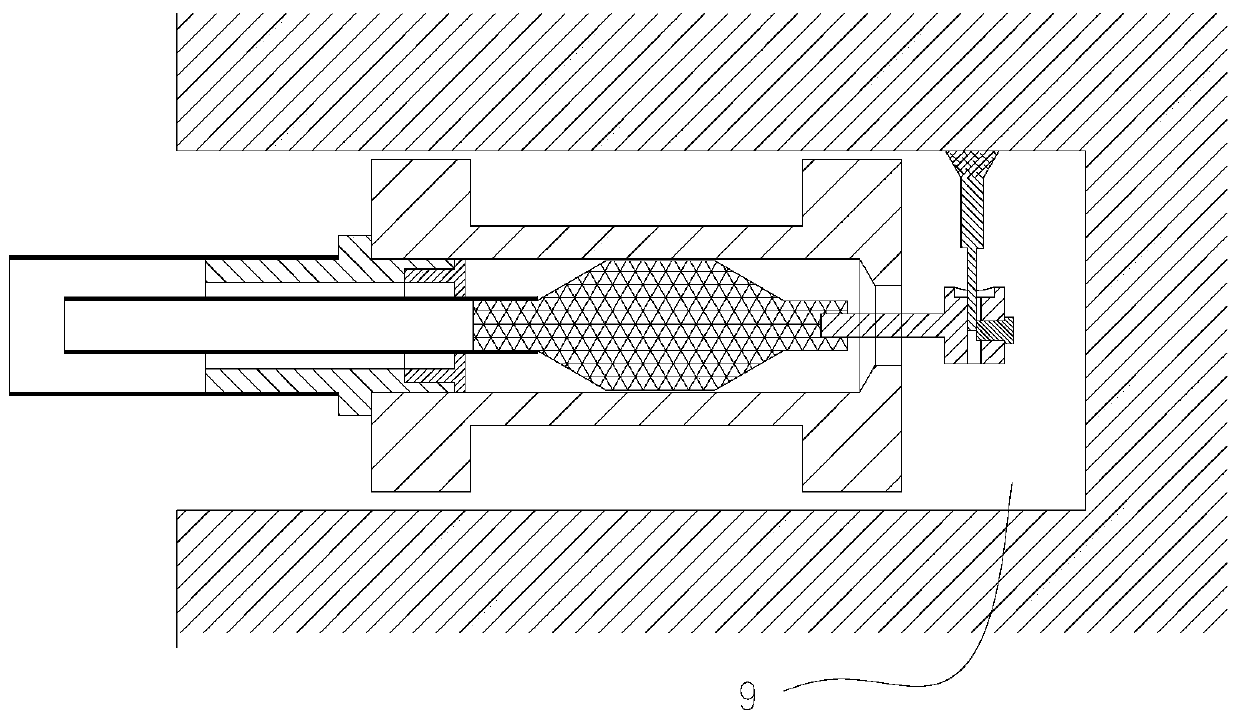

[0035] The stent body 1 is a hollow cylindrical structure, and the outer diameter of the stent body 1 is smaller than the inner diameter of the deep hole 9. Specifically, the outer diameter of the stent body is generally less than about 3mm of the cleaning hole, which can ensure the entire device to a certain extent. The stability in the deep hole 9 can ensure that the movement of th...

Embodiment 2

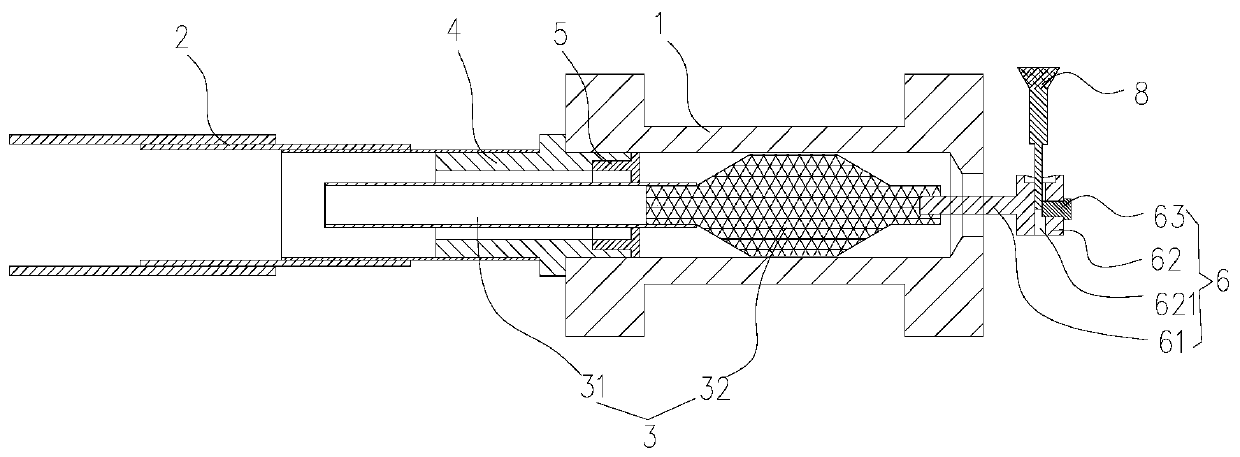

[0045] like figure 2 As shown, the handle 2 is a plurality of telescopically connected hollow steel pipes. The outer diameters of the multiple hollow steel pipes increase sequentially. connected to the outside. The means to achieve shrinkage can be: setting a slider in one of the two relatively interacting hollow steel pipes, and setting a chute in the other, so that relative sliding can be achieved, and expansion and contraction can be achieved; other structures that can achieve expansion and contraction can also be used. can be referenced.

[0046] The telescopic structure realized by a plurality of hollow steel pipe parts meets the needs of different deep holes 9 and has stronger adaptability.

[0047] It should be noted that: if figure 1 , 2 As shown, the cleaning member 7 in the first embodiment and the second embodiment is a brush. One end of the brush is a round rod for easy insertion into the through hole, and the other end is a cleaning head. The grinding piece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com