Mortar spraying, scraping and plastering device

A mortar and scraper technology, applied in construction, building structure, etc., can solve the problems of low scraping efficiency, great influence of spraying work, and excessive use of raw materials, so as to reduce the requirements of technical skills, improve production efficiency and quality, The effect of improving the scraping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

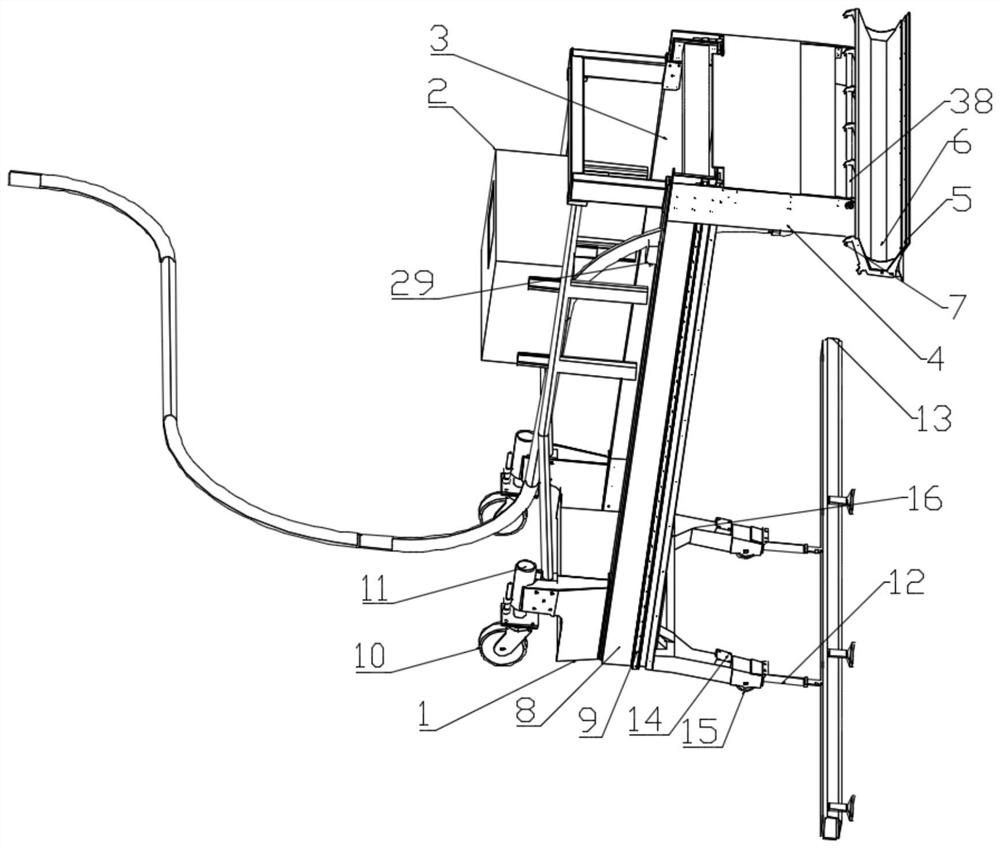

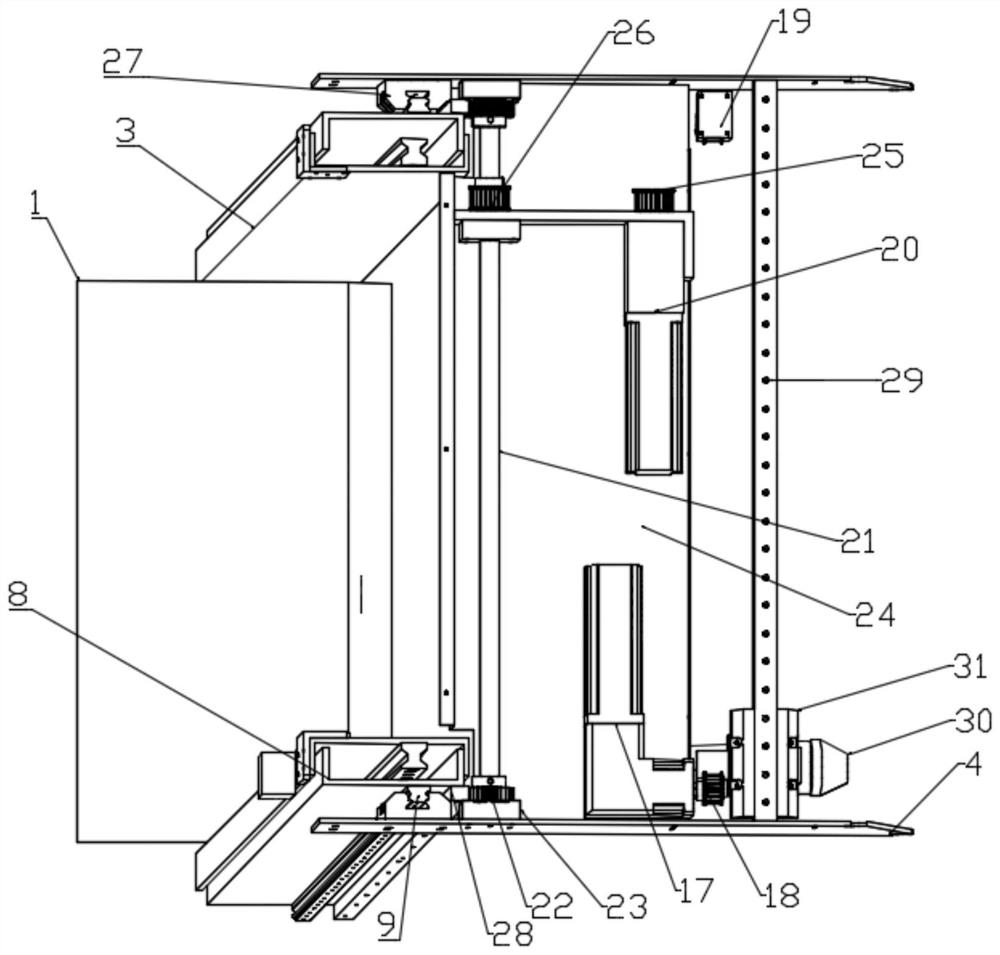

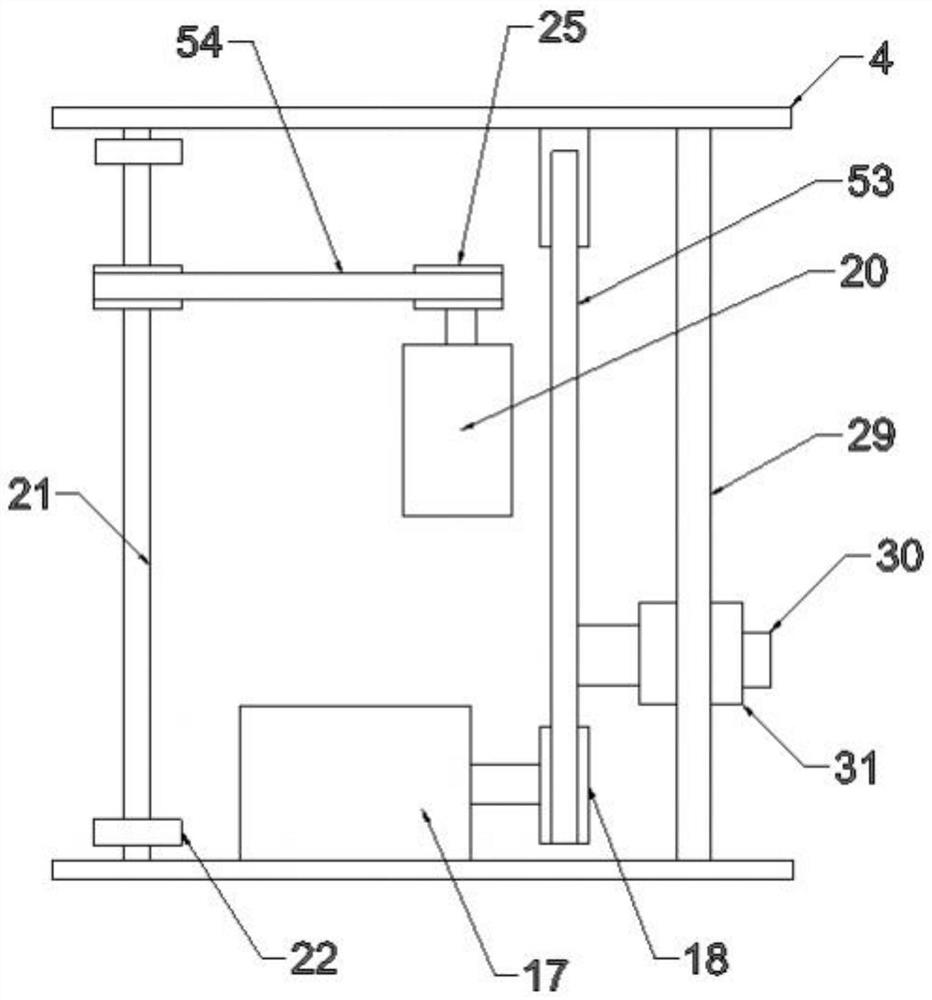

[0037] refer to Figure 1-5 , the present invention provides a mortar spraying and scraping device, comprising a frame 1, a column 3 is symmetrically arranged on the frame 1, a spraying assembly is slidably connected to the column 3, and a scraper is detachably connected to the end of the spraying assembly away from the column 3 components;

[0038] The bottom of the frame 1 is provided with a reference line adjustment part and a verticality adjustment part; the side of the frame 1 is provided with a controller 2, and the spraying assembly, the reference line adjustment part, and the verticality adjustment part are all electrically connected to the controller 2.

[0039] In a further preferred solution, the spraying assembly includes a nozzle head, a horizontal moving part and a vertical moving part, and the horizontal moving part includes symmetrically arranged side plates 4, and a slide bar 29 and a support plate 24 are fixedly connected between the two side plates 4, and th...

Embodiment 2

[0049] refer to Figure 6-9 , the scraper assembly in this embodiment is a double scraper, the double scraper includes an upper scraper 42, a lower scraper 45, and a push rod, the upper scraper 42 includes an upper scraper 42, an upper scraper 43, and the upper scraper The plate 42 is fixedly connected with the upper scraper bar 43, and the upper scraper bar 43 is an arc-shaped bar. The end of the upper scraper bar 43 away from the upper scraper plate 42 is provided with an arc-shaped groove 52. Adaptation, the lower scraper 45 includes a lower scraper 45, a lower scraper 46, the lower scraper 45 is fixedly connected to the lower scraper 46, and a connecting rod 48 is arranged between the upper scraper 43 and the lower scraper 46, and the connecting rod One end of 48 is hinged with the upper scraping rod 43, the other end of the connecting rod 48 is hinged with the lower scraping rod 46, and the ends of the two side plates 4 away from the column 3 are detachably connected with...

Embodiment 3

[0054] refer to Figure 10 The only difference between this embodiment and Embodiment 2 is that the reference line adjustment part in this embodiment is a manual adjustment part, and the manual adjustment part includes two channel steels 56, and the two channel steels 56 are arranged symmetrically. The bottom surface of the channel steel 56 is fixedly connected with a screw mandrel 57, and the two screw mandrels 57 are provided with reverse threads, and the two screw mandrels 57 are externally threaded with a sleeve 58, and one of the channel steels 56 is far away from the The end of the screw mandrel 57 is fixedly connected with a fixed rod 59, and the fixed rod 59 is fixedly connected on the support beam 16. In this implementation, before adjusting the reference line, the channel steel 56 away from the fixed rod 59 is close to the On the wall, by manually rotating the sleeve 58, the two screw rods 57 move away from each other until the end surface of the channel steel 56 clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com