Novel RTV (Room Temperature Vulcanization) device for spraying 110kV GIS (Gas Insulated Switchgear)outgoing line bushing insulator

An outlet bushing and insulator technology is applied in the field of the new 110kV GIS outlet bushing insulator spraying RTV device, which can solve the problems of error, uneven coating adhesion, affecting the spraying effect, etc., and achieve the effect of ensuring the spraying effect and the uniform spraying effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

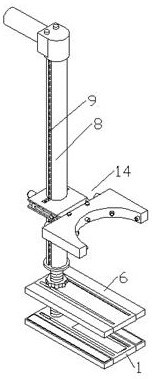

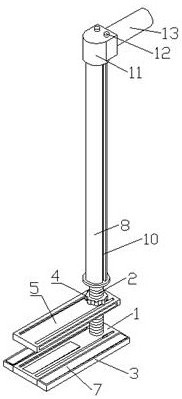

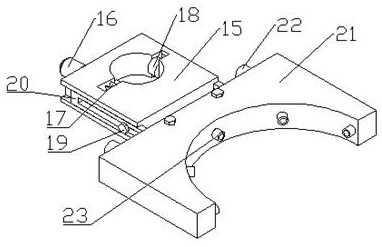

[0014] Such as Figure 1-3 As shown, a new 110kV GIS outlet bushing insulator spraying RTV device, including the lower splint 1, the screw 2, the lower splint 3, the screw barrel 4, the upper splint 5, the upper splint 6, the anti-slip rubber strip 7, the guide rod 8, Rack 9, guide groove 10, controller 11, button switch 12, handle 13, spraying part 14, screw rod 2 is fixed on the top left part of the lower splint 1, and the front and rear parts of the lower splint 1 are slidingly connected with lower extensions Splint 3, the upper part of the screw rod 2 is threadedly connected with a screw barrel 4, and the outer wall of the screw barrel 4 is rotatably connected with an upper splint 5 through a bearing, and the position of the upper splint 5 on the screw rod 2 can be adjusted by manually rotating the screw barrel 4 , so as to realize the cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com