Percussion safety mechanism of cutting anastomat, percussion device and anastomat thereof

A firing safety and firing device technology, which is applied in the field of medical staplers, can solve the problems of rapid cutting and suturing of unfavorable tissues, poor suturing, and inability to lock inductively, so as to avoid poor suturing, prevent tissue damage, and improve the efficiency of suturing and cutting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

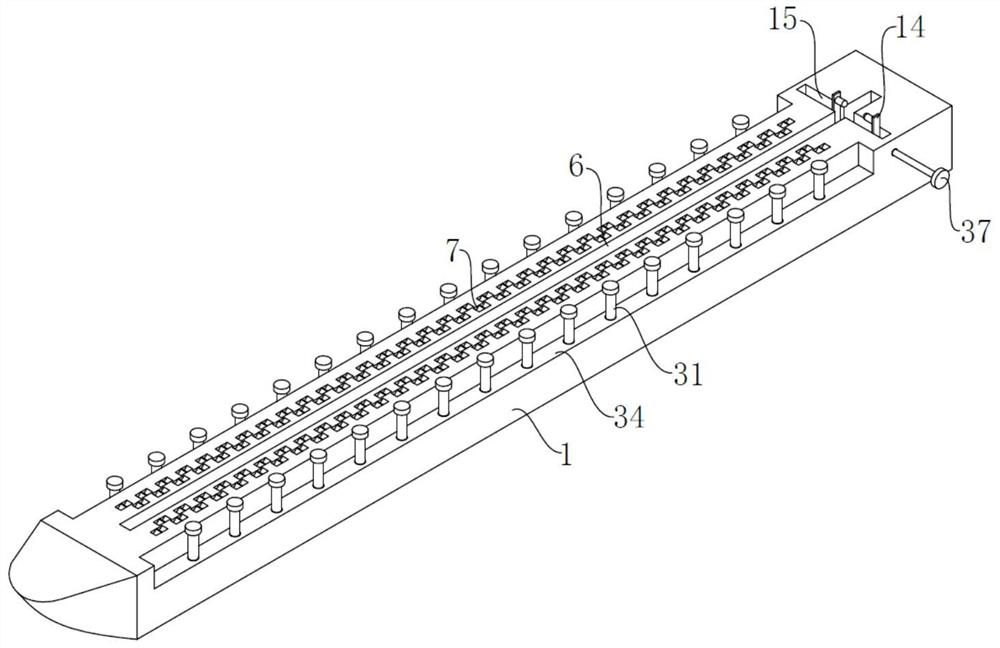

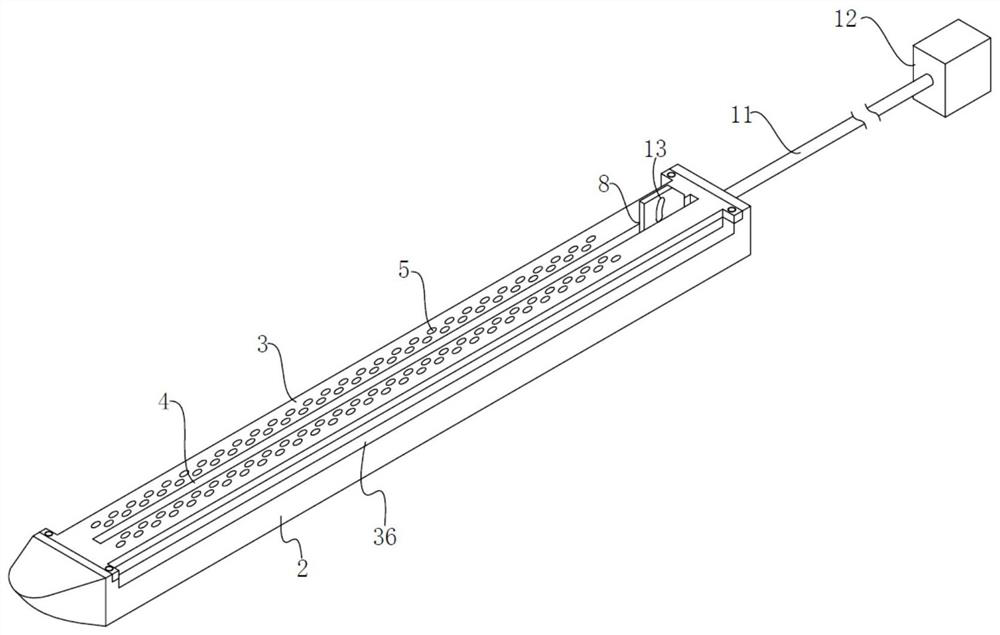

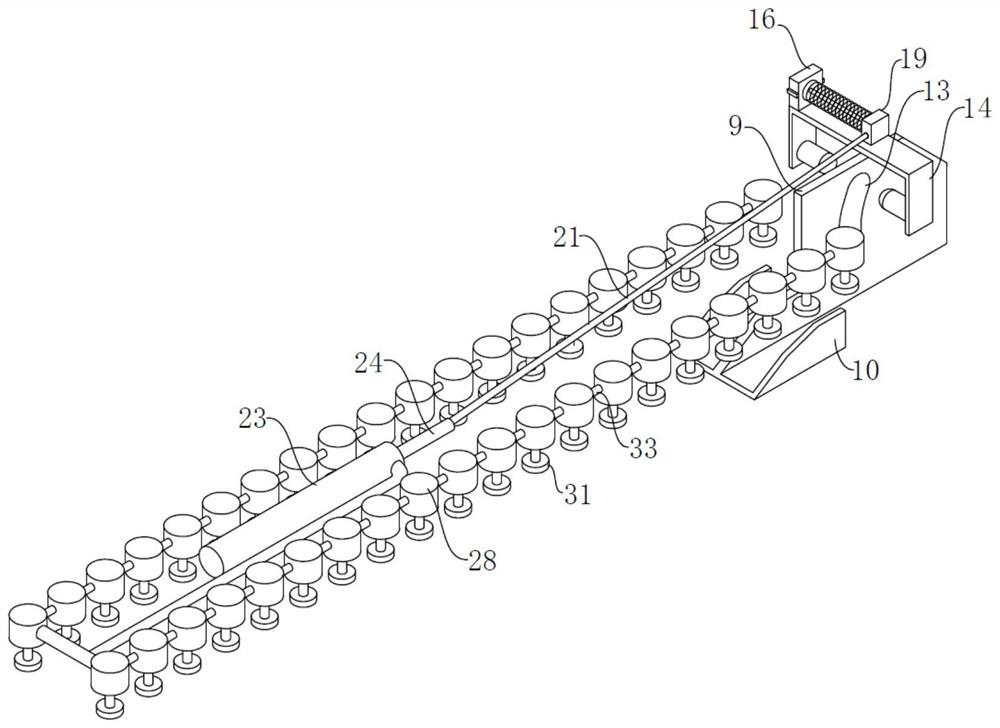

[0031] see Figure 1-10 , the present invention provides a technical solution:

[0032] A firing safety mechanism for a cutting stapler, comprising a nail abutment seat 1 and a nail capsule seat 2, the nail abutment seat 1 and the nail capsule seat 2 are set up and down correspondingly, a nail capsule 3 is fixedly installed on the nail capsule seat 2, and the middle part of the nail capsule 3 Cutting slots 4 are provided, nail outlet holes 5 are arranged in an array on the nail bays 3 on both sides of the cutting slots 4, and the middle part of the anvil seat 1 is provided with cutting matching slots 6 corresponding to the cutting slots 4, and the cutting matching slots 6 are arrayed on both sides. There are nail abutting grooves 7 corresponding to the nail outlet holes 5 one by one;

[0033] The tissue to be cut and sutured is clamped by the upper and lower closure of the nail anvil 1 and the nail cabin 2, and then it is sutured and cut. The used nail cabin 3 can be removed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com