Rotary double-spindle edge trimmer

A trimming machine and dual-spindle technology, which is applied in metal processing and other directions, can solve the problems of unstable turning operation, difficult cleaning of waste, and low flash separation rate, so as to ensure flash separation rate, improve trimming efficiency, avoid unstable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

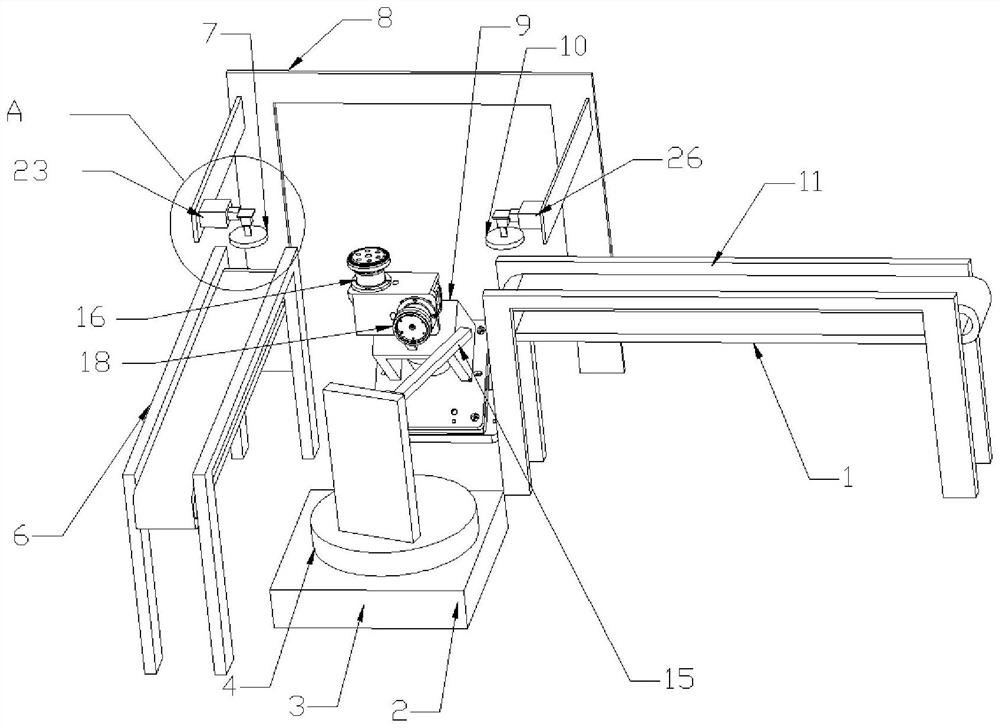

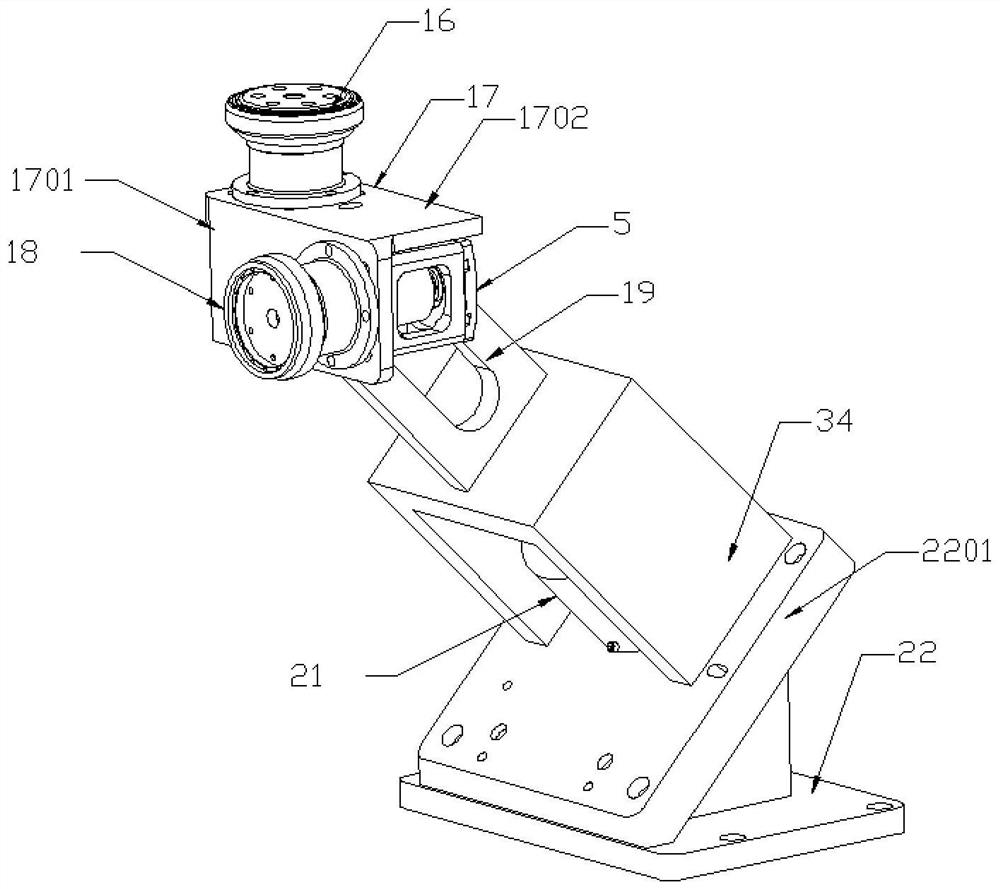

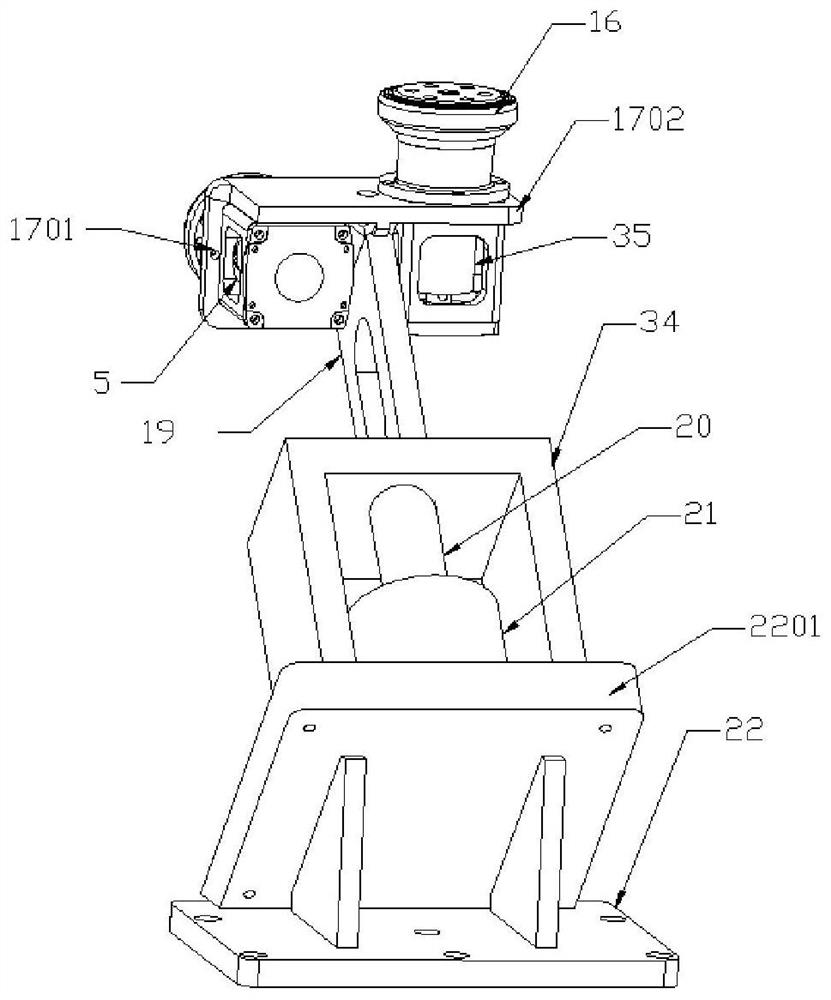

[0025] to combine Figures 1 to 6 Shown, a kind of rotary dual-spindle trimming machine, trimming machine includes feeding conveying line 6, unloading conveying line 11, support 8, car side mechanism 3, conversion mechanism, first clamp 18, second clamp 16; The mechanism includes a support 22, a conversion frame 17, and a main shaft system 9; the support 22 is located at one side of the support 8; the conversion frame 17 is rotatably arranged on the support 22 through the main shaft system 9; the first clamp 18, the second The clamp 16 is rotatably arranged on the conversion frame 17; the car side mechanism 3 is located at a position close to the conversion frame 17; The clamping claw I7 and the clamping claw II10 for blanking that can move horizontally along the feeding conveyor line 11 and the conversion frame 17; the conversion frame 17 can be driven by the spindle system to rotate to the first state or the second state; when the conversion frame 17 When in the first state...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com