Down feather processing system and process

A processing system and down technology, which is applied in the field of down processing, can solve the problems of not being able to record the test results of down bulkiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

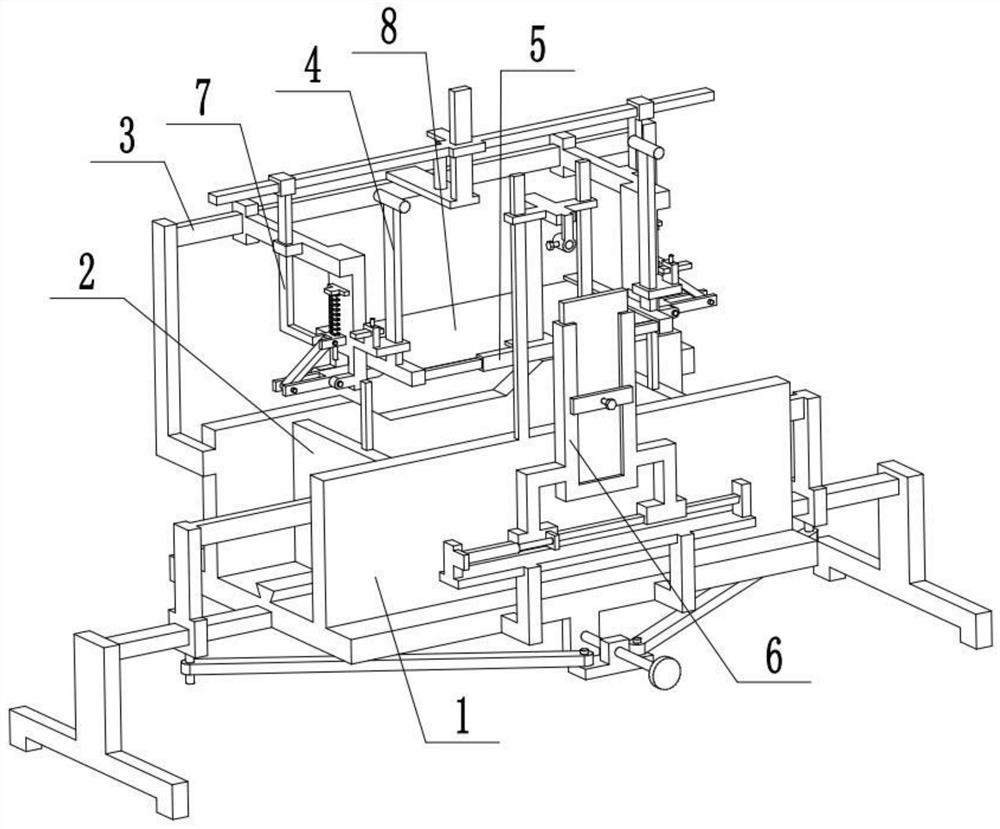

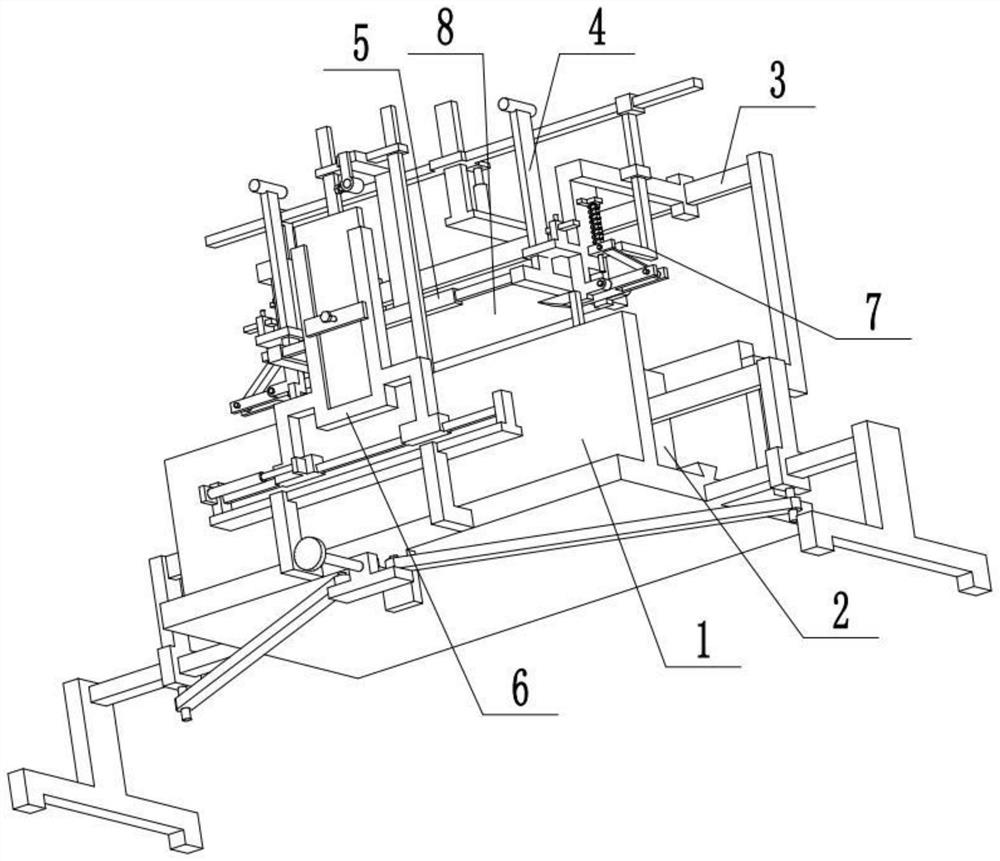

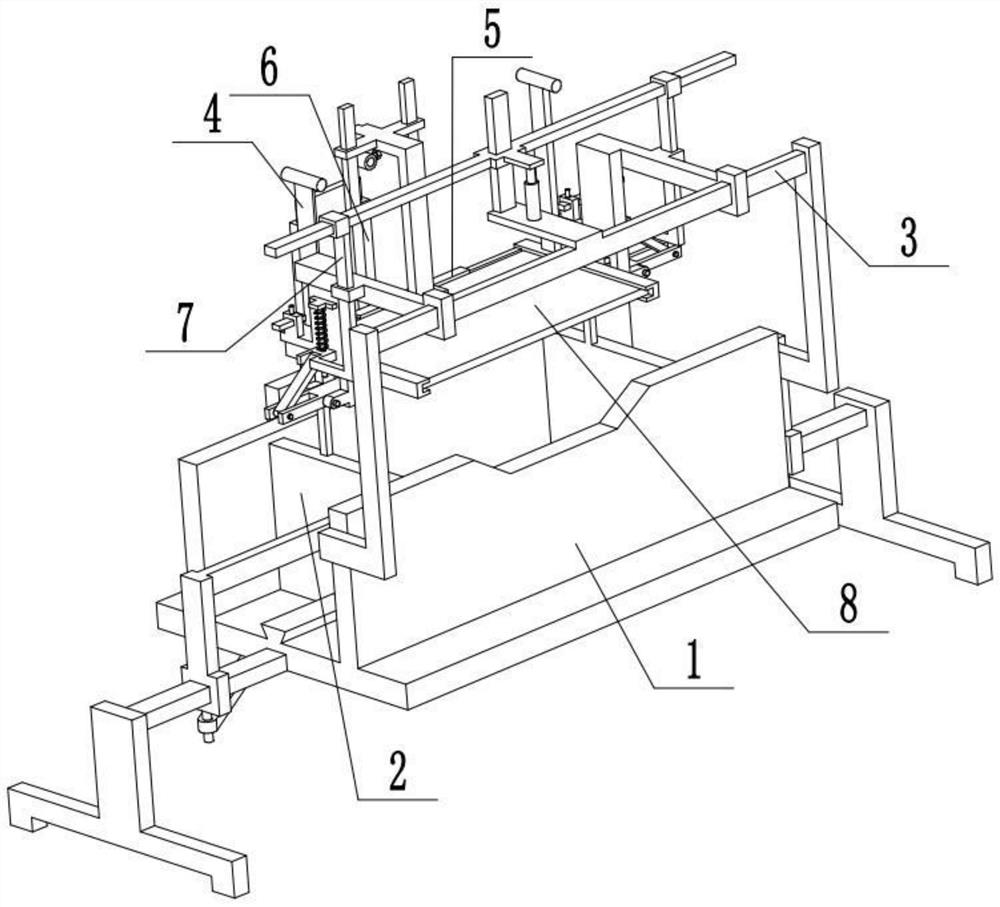

[0035] Combine below Figure 1-9Describe this embodiment, a down processing system, including a down box 1, a side plate 2, a horizontal frame 3, a slide bar 4, a U-shaped frame 4-1, a sleeve bar 5, a fixing frame 5-1, and a sleeve 5-2 , U-shaped cover plate 6, drawing board 6-1 and aluminum plate 8, two side panels 2 are arranged in the inside of the described velvet box 1, the horizontal frame 3 is arranged on the velvet box 1, and the two ends of the horizontal frame 3 are movable respectively A slide bar 4 is connected, and the lower ends of the two slide bars 4 are fixedly connected to a U-shaped frame 4-1, and the two U-shaped frames 4-1 are respectively connected to the two ends of the sleeve rod 5, and the sleeve rod 5 is fixedly connected and fixed. The frame 5-1, the front end of the fixed frame 5-1 is fixedly connected to the sleeve 5-2, the sleeve 5-2 is threaded to connect the locking screw, and the drawing board 6-1 is connected by clearance fit and slidingly con...

specific Embodiment approach 2

[0037] Combine below Figure 1-9 To illustrate this embodiment, the described down processing system also includes a base foot 6-3, a trapezoidal rod 6-4, a fixing seat 6-5, a first electric push rod 6-6, and two ends of a U-shaped cover plate 6 One foot 6-3 is fixedly connected respectively, and the two feet 6-3 are all slidably connected to the trapezoidal rod 6-4, the trapezoidal rod 6-4 is fixedly connected to the fixing seat 6-5, and the fixing seat 6-5 is fixedly connected At the front end of the cashmere box 1, the first electric push rod 6-6 is fixedly connected to the fixing seat 6-5, and the telescopic end of the first electric push rod 6-6 is fixedly connected to a foot 6-3. When in use, the down and down of different qualities or batches are put into the down box 1 for testing. Whenever a batch of down is replaced, the first electric push rod 6-6 starts to drive the U-shaped sleeve through the foot 6-3. The plate 6 moves left and right on the trapezoidal rod 6-4, ...

specific Embodiment approach 3

[0039] Combine below Figure 1-9 Describe this embodiment, described a kind of eider down treatment system also comprises vertical frame 1-3, L-shaped board 3-1, L-shaped seat 3-2, rod seat 3-4, sleeve rod 3-5, hinge block 3 -6, hinge rod 3-7 and baffle plate 3-8, the rear end of cashmere box 1 is fixedly connected with two vertical frames 1-3, horizontal frame 3 is fixedly connected between two vertical frames 1-3, horizontal frame 3 Two L-shaped plates 3-1 are arranged on the top, and the inner ends of the two L-shaped plates 3-1 are respectively fixedly connected to an L-shaped seat 3-2, and the two sliding rods 4 are respectively slidably connected to the two L-shaped seats 3-2. Inside, the outer ends of the two L-shaped plates 3-1 are respectively fixedly connected to a rod base 3-4, and the two rod bases 3-4 are respectively fixedly connected to a sleeve rod 3-5, and the two sleeve rods 3-5 are respectively fixedly connected to each other. A articulated block 3-6 is sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com