Supporting platform for mounting of steel structure industrial factory building

A technology for industrial workshops and supporting platforms, which is applied to the preparation of pillars, building structures, and building components on site, and can solve the problems of wasting time for lifting I-beams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

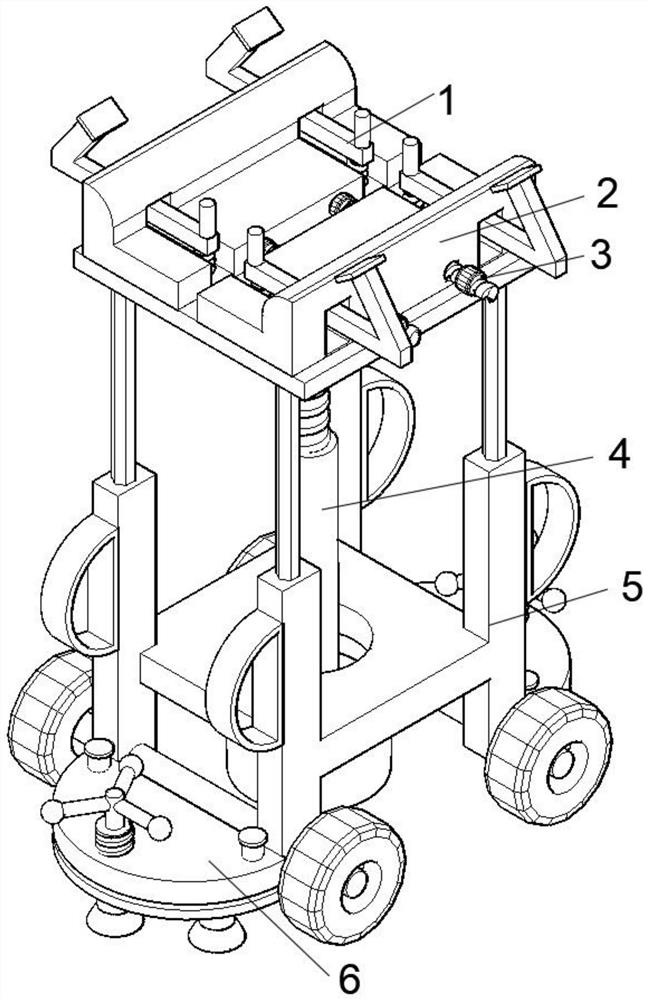

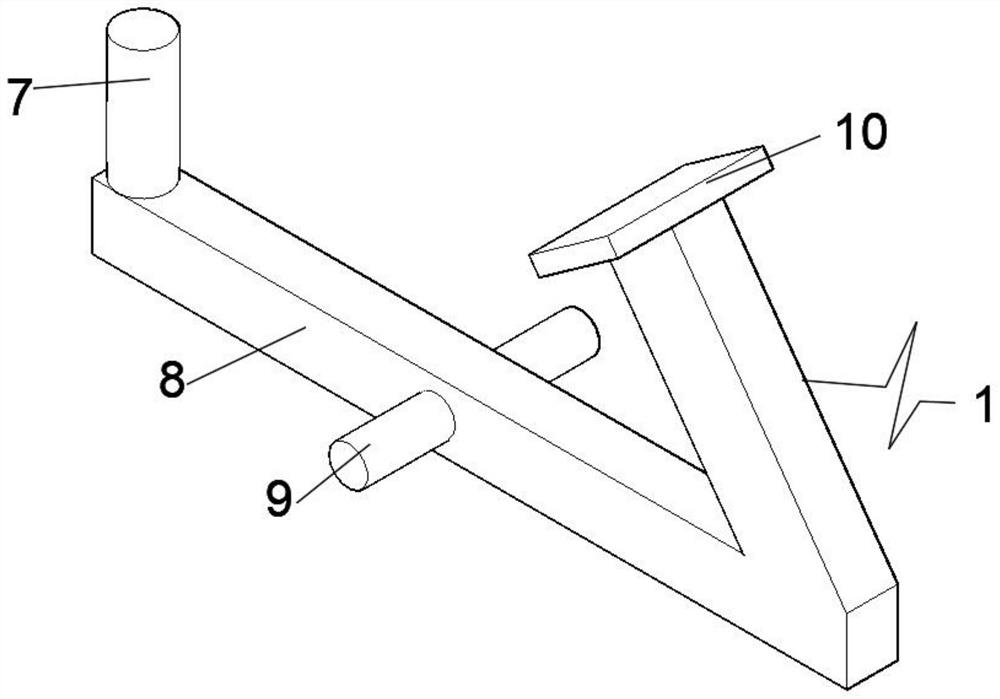

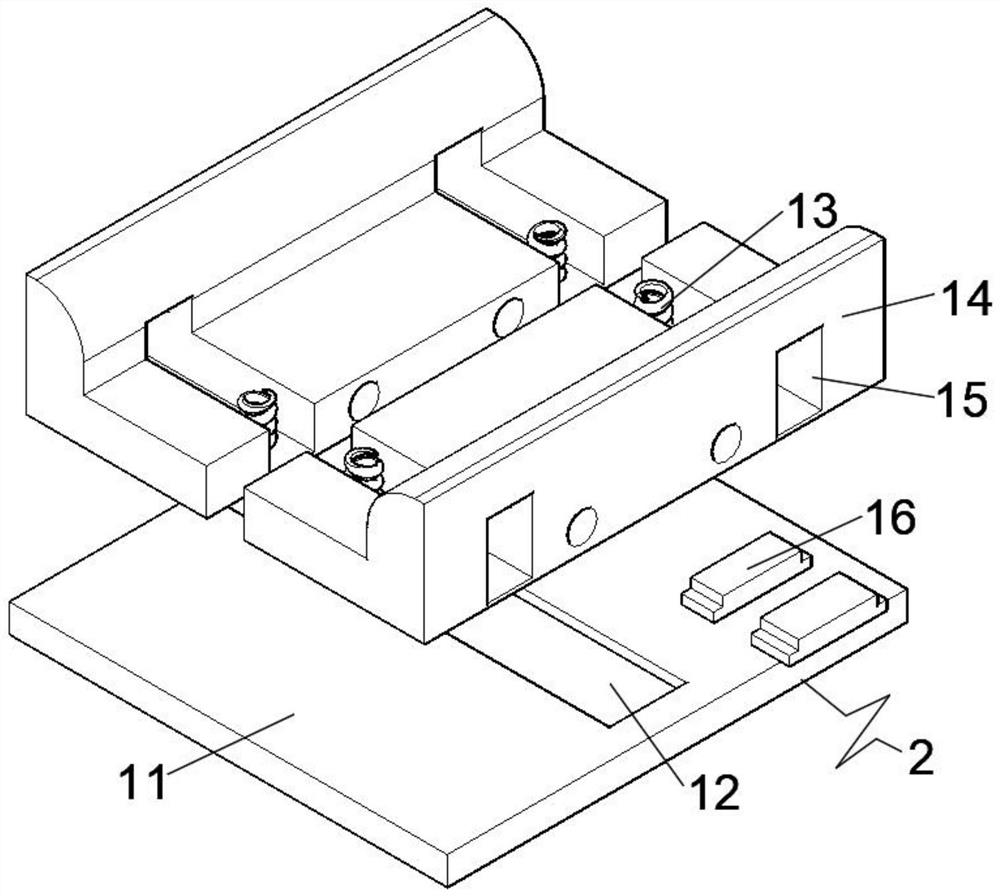

[0029] see Figure 1-7, an embodiment provided by the present invention: a support platform for installation of a steel structure industrial plant, including a mobile chassis 5, the interior of the mobile chassis 5 is fixedly connected with a transmission device 4, and the top of the transmission device 4 is fixedly connected with an adjustment base 2, Both sides of the adjustment base 2 are slidingly inserted into the limit device 3, and the internal symmetrical rotation of the adjustment base 2 is connected with a clamping rod 1, and the two ends of the mobile chassis 5 are fixedly welded with a stable limiter 6. The clamping rod 1 includes the first The supporting column 7, the first limiting rod 8, the first rotating rod 9 and the first extruding plate 10, the first supporting column 7 is fixedly welded on one end of the first limiting rod 8, and the first extruding plate 10 is fixedly welded On the other end of the first limiting rod 8, the first rotating rod 9 is symmetr...

Embodiment 2

[0032] On the basis of Example 1, such as Figure 8 As shown, the clamping rod 1 includes a second extruding plate 32, a second limiting rod 33, a second rotating rod 34, a gasket 35 and a second support column 36, and the second extruding plate 32 is fixedly connected to the second limiting rod. On one end of the position rod 33, the second support column 36 is fixedly connected on the other end of the second position limit rod 33, the gasket 35 is fixedly connected to the top of the second support column 36, and the second rotating rod 34 is symmetrically fixedly connected to the second On the side end of the limiting rod 33 , the material of the gasket 35 is wear-resistant rubber, and the second extruding plate 32 is provided with anti-slip lines.

[0033] In this embodiment, anti-slip lines are provided on the second extrusion plate 32 during implementation, so that the friction force when clamping the I-beam can be improved, and the gasket 35 is fixedly connected to the t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap