PCB for frequency conversion of operating lamp

A PCB board and surgical lamp technology, applied in the field of surgical lamps, can solve the problems of increasing PCB board material use process and installation process, PCB board damage, scrapping, etc., to achieve the effect of convenient and flexible movement, avoiding serious damage, and avoiding drilling operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

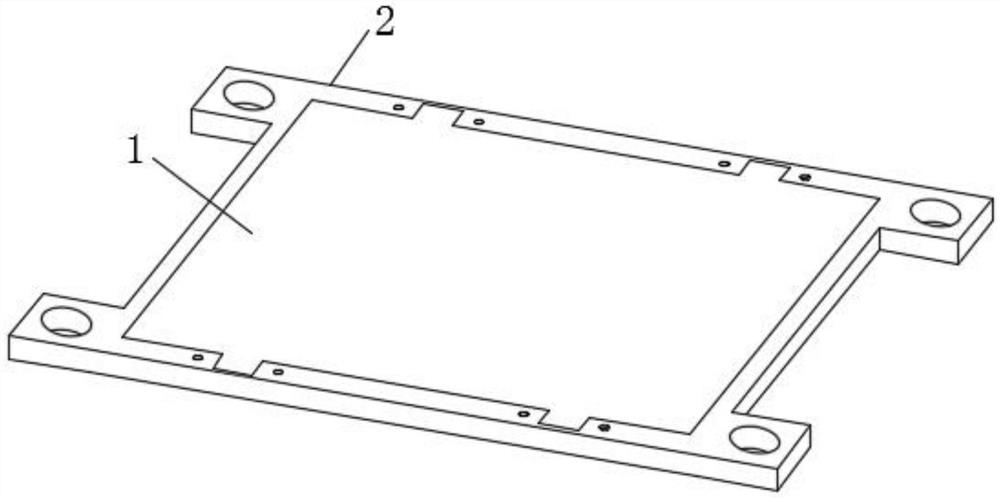

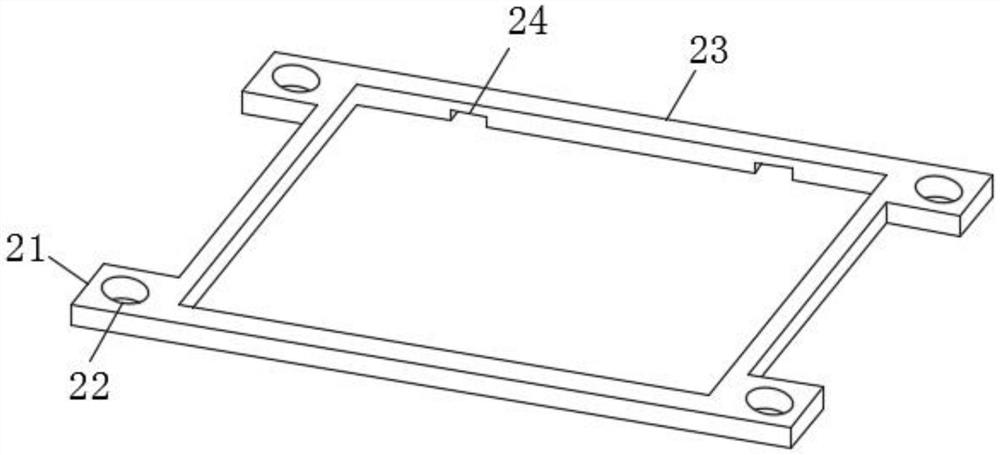

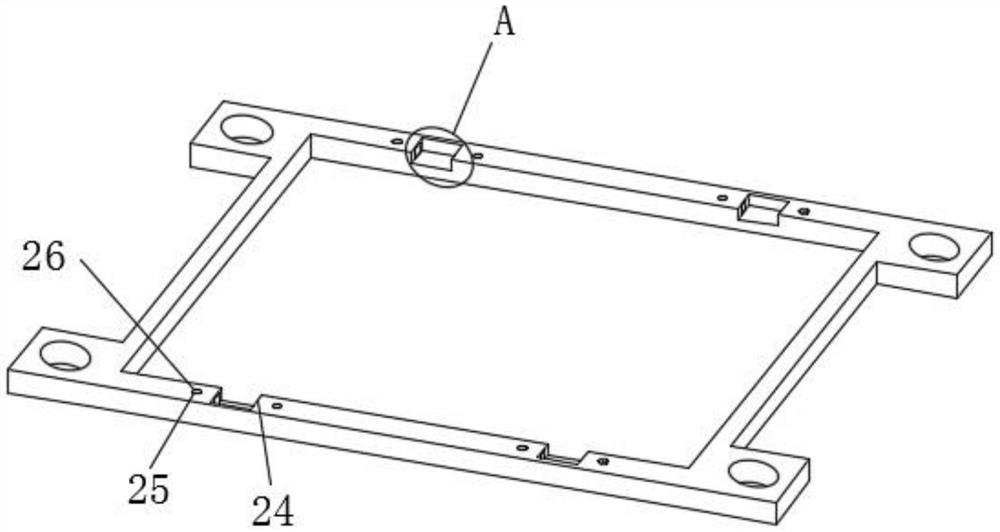

[0035] see Figure 1-7 As shown, a PCB board for frequency conversion of operating lights includes a PCB board body 1 and a disassembly assembly 2, and the disassembly assembly 2 includes a mounting part 21, a mounting hole 22, a mounting frame 23, a clamping groove 24, and a cylindrical hole 25 , rotating rod 26, clamping plate 27, rectangular movable groove 28, rectangular movable rod 29, rectangular threaded groove 291 and threaded mounting ring 292;

[0036] The outside of the PCB board body 1 is provided with a mounting frame 23, and the inner wall of the mounting frame 23 is provided with four sets of clamping grooves 24, and the two side walls of the four sets of clamping grooves 24 are symmetrically installed with clamping plates 27. The inside of the installation frame 23 is provided with a rectangular movable groove 28, which is located on both sides of the clamping groove 24, and a rectangular movable rod 29 is installed inside the rectangular movable groove 28, and...

Embodiment 2

[0042] A PCB board for frequency conversion of an operating light, and the working steps of the PCB board for frequency conversion of the operating light are as follows:

[0043] Step 1: Open installation holes 22 in the installation part 21 on the installation frame 23, four sets of clamping slots 24 are provided on the inner side of the installation frame 23, rectangular movable slots 28 are opened symmetrically on both sides of the clamping slots 24, and then the rectangular movable slots 28 are opened in the rectangular movable slots. A rectangular threaded groove 291 is provided inside the rod 29, the threaded fixing ring is assembled in the rectangular threaded groove 291, the rectangular movable rod 29 is fixedly connected with the clamping plate 27, and finally the rectangular movable rod 29 is embedded in the rectangular movable groove 28, and the installation frame 23 is preliminary complete assembly;

[0044] Step 2, the staff screw the lower end of the rotating rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com