Multifunctional grounding assembly

A multi-functional, component technology, applied in the direction of connecting contact material, clamping/spring connection, etc., can solve the problems of difficult to connect the ground wire, use a lot of tools, increase the workload of arranging safety measures, etc., to reduce the number and operation. convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

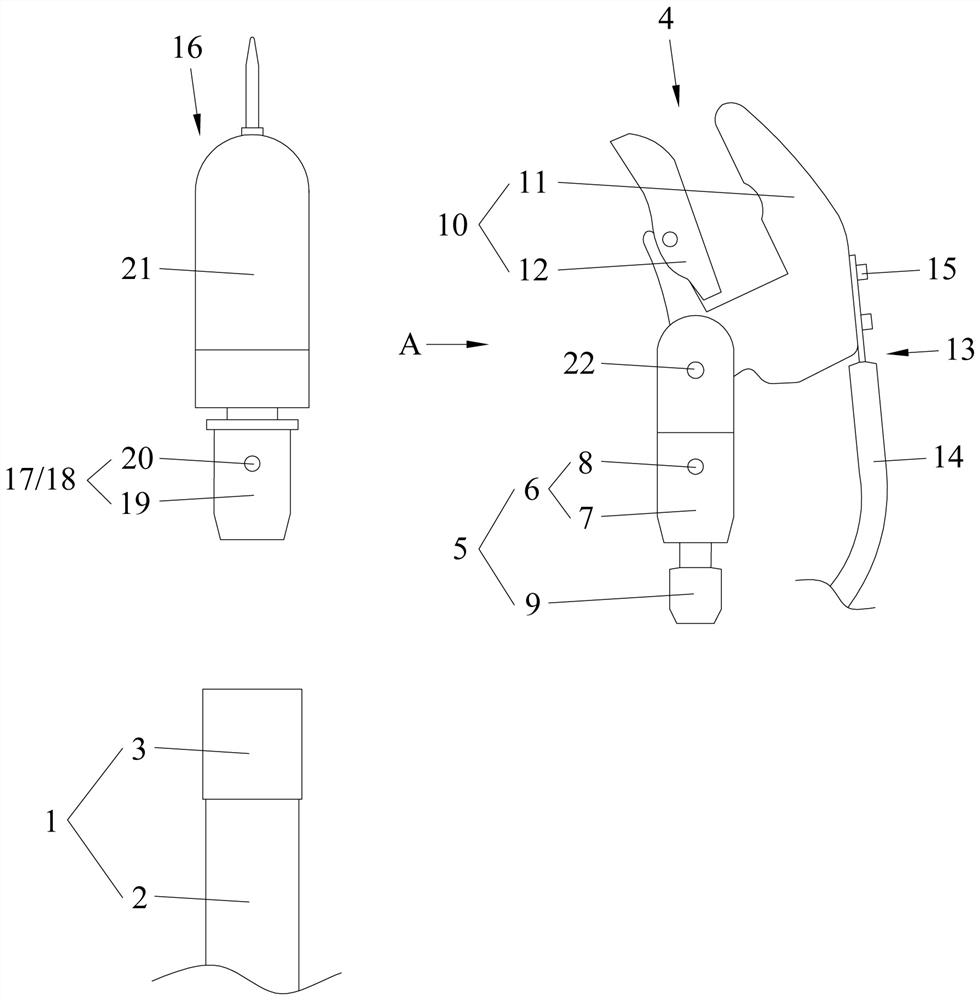

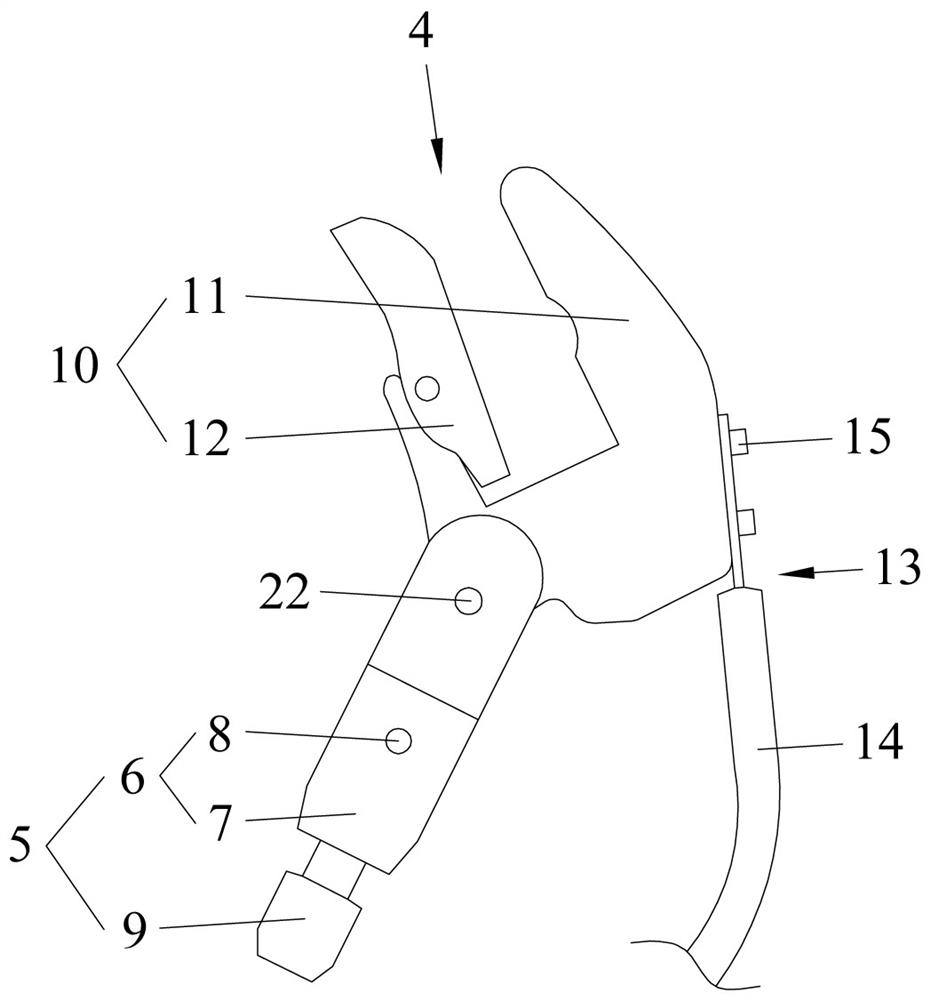

[0029] Embodiment one: as attached figure 1 And attached figure 2 As shown, a multi-functional grounding assembly includes an insulating operating rod 1, several grounding terminals 4 and electrical testing terminals 16, wherein the several grounding terminals 4 can be divided into several groups for use, and the grounding terminals Both the head 4 and the electric test terminal 16 can be detachably installed on the front end of the insulating operating rod 1 .

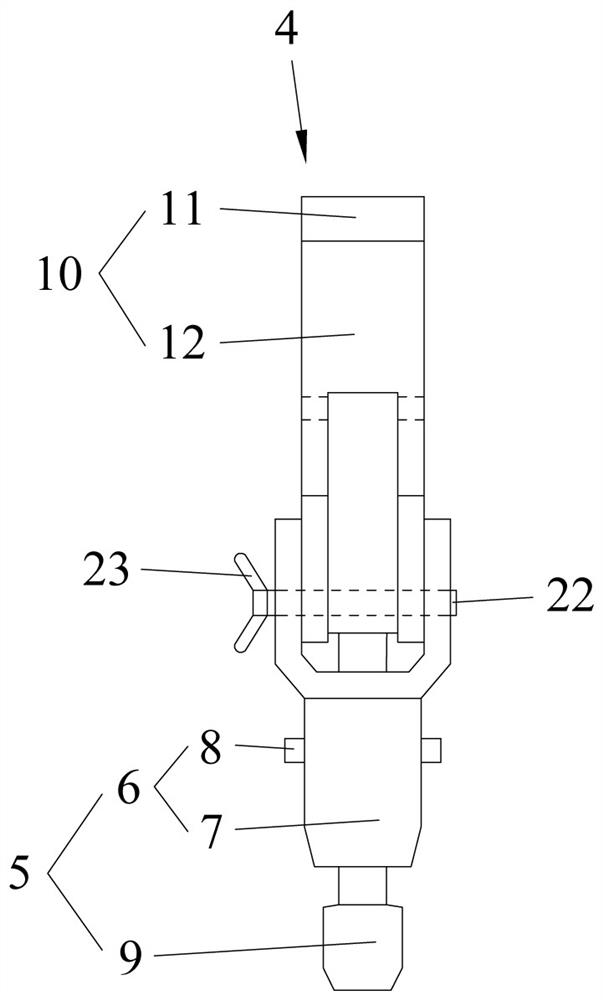

[0030] The ground terminal 4 includes a ground connector 5 , a ground clamp 10 and a ground wire 13 . The ground connector 5 is detachably mounted on the front end of the insulating operating rod 1 , the ground clamp 10 is rotatably mounted on the ground connector 5 , and the ground wire 13 is connected with the ground clamp 10 . Wherein, the grounding clamp 10 is rotatably mounted on the grounding connector 5 through the rotating shaft 22 , and the grounding clamp 10 is provided with a knob 23 for position locking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com