Fiber solid waste collection and treatment equipment

A solid waste and treatment equipment technology, applied in cleaning equipment, recycling technology, vacuum cleaners, etc., can solve the problems of broom cleaning troubles, dust suction pipes are not easy to block, bend, and block, so as to avoid direct contact, reduce labor intensity, Effect of improving collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

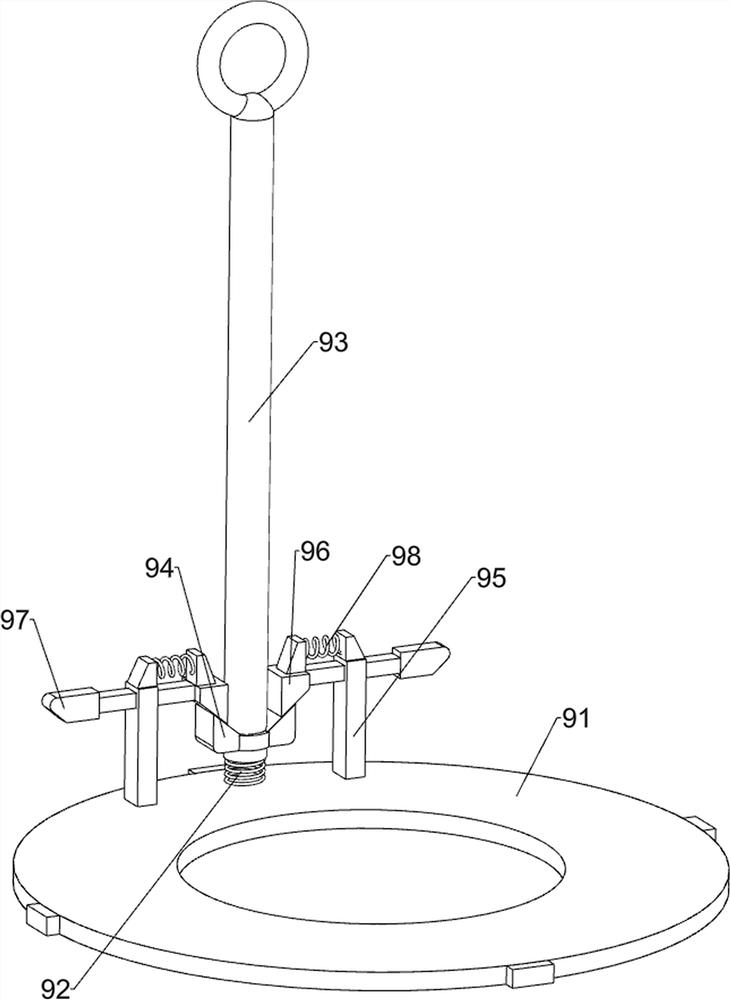

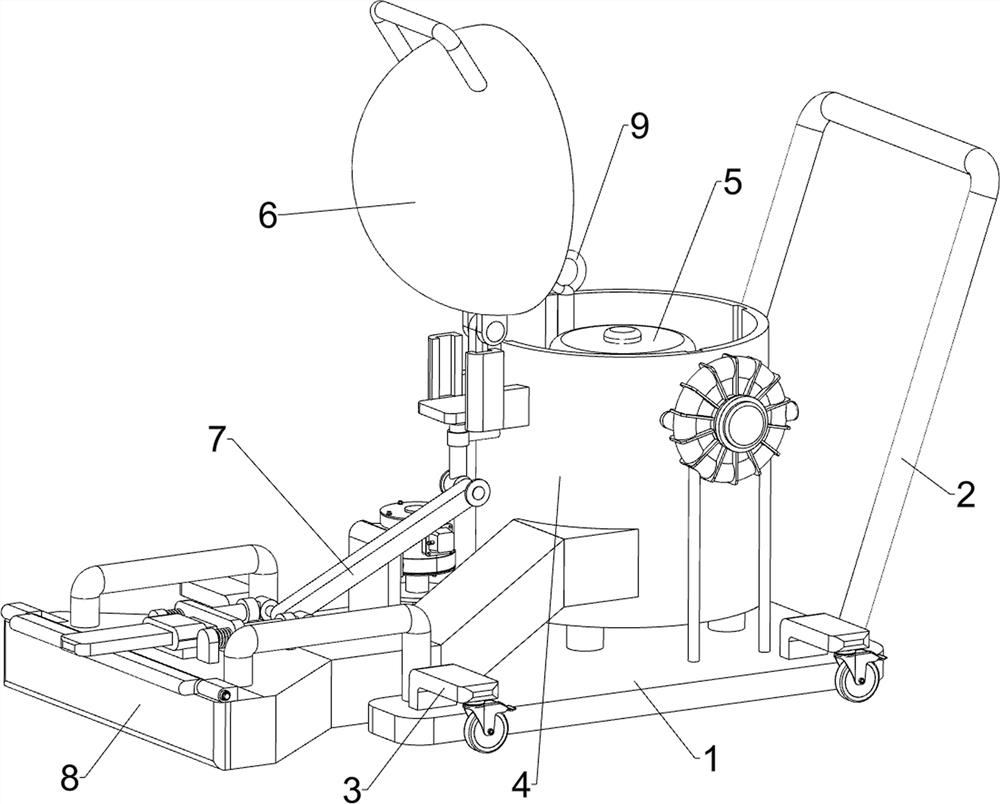

[0026]Fiber solid waste collection processing equipment, such asFigure 1 to 3As shown, including the bottom plate 1, the hand push rod 2, the wheel frame 3, the wind suction mechanism 4, the collecting mechanism 5, and the barrel cover mechanism 6, and the top right side of the bottom plate 1 is connected to the top of the bottom plate 2, the bottom plate 1 top The wheel frame 3 is connected, and the wind absorbing mechanism 4 is attached to the middle of the bottom plate 1, and the bottom plate 1 is connected between the bottom plate 1 and the wind absorbing mechanism 4, and the winding mechanism 4 is connected to the wind suction mechanism 4.

[0027]The wind absorbing mechanism 4 includes a support post 41, a collection tub 42, a drawing conduit 43, a fixing frame 44, a winder 45, and a support frame 46, and four support columns 41 are connected in the middle of the bottom plate 1, and four support column 41 top. The collected tub 42 is connected between the collected tub 42, and th...

Embodiment 2

[0032]On the basis of Example 1, such asimage 3 withFigure 5 As shown, there is a baffle mechanism 8, and the baffle mechanism 8 includes a mount 81, a scroll spring 82, a movable baffle 83, and a bump 84, and the front and rear ends of the absorbing conduit 43 are connected to the mount 81. The movable baffle 83 of the mounting seat 81 on both sides is rotated between the moving absorbent pipe 43, and the active baffle 83 is connected to the movable block 83 and the movable plate 83 and the mounting seat 81 are connected to the scroll spring. 82.

[0033]When the fiber waste is not required, the inlet of the active baffle 83 blocks the absorbent conduit 43, so that the fiber waste in the collection tub 42 can be avoided. Open the active baffle 83 cover when collecting fiber waste.

Embodiment 3

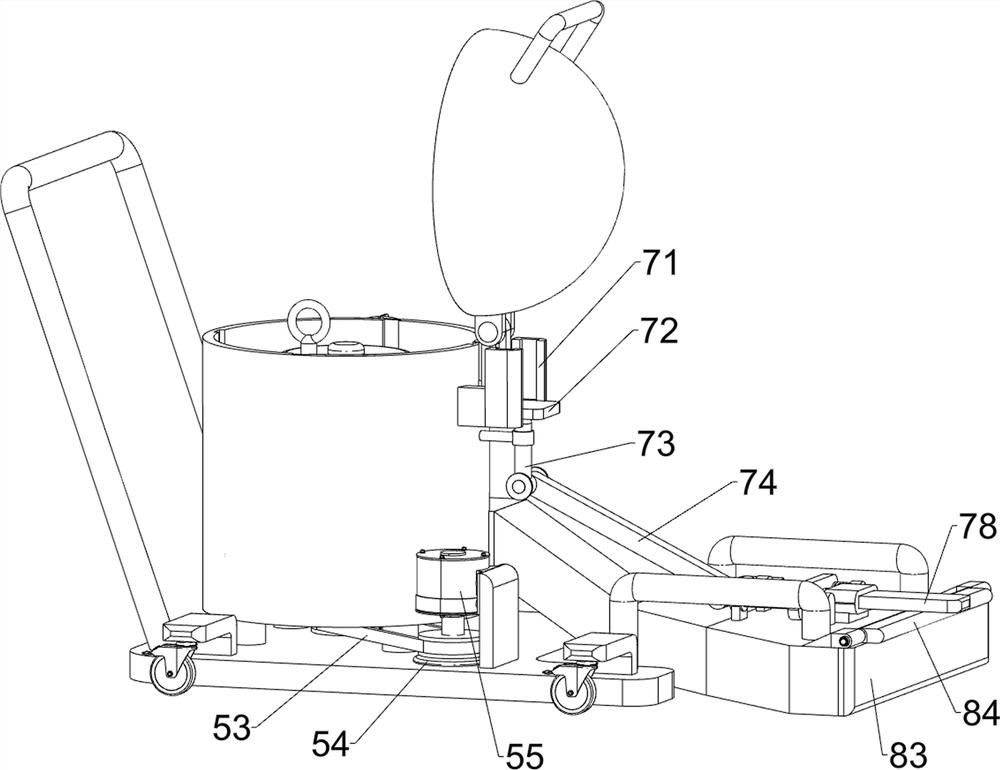

[0035]On the basis of Example 2, such asimage 3 withFigure 5 As shown, there is also a linkage mechanism 7, the linkage mechanism 7 includes a guide rail 71, a sliding push plate 72, a first rod 73, a link 74, a second rod 75, a first guide sleeve 76, a second guide sleeve 77, the push rod 78, the fixing block 79 and the first reset spring 710, the upper portion of the collecting tub 42 is connected to the rail holder 71, the guide rails 71 slidely connected to the sliding push plate 72, the bottom of the sliding push plate 72 is connected. The first rod 73, the top left side of the top of the suction conduit 43 is connected to the two first guide sleeve 76 and two fixed blocks 79, and the first guide sleeve 76 is located on the right side of the fixed block 79, the first guide sleeve 76 sliding type The second rod 75 is connected to the second rod 75, and the upper right end of the second rod 75 is hinged between the bottom end of the first hose 73, and the connecting rod 74 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com