Device for producing gradient-color 3D printing consumables and production method thereof

A 3D printing and gradient color technology, applied in the direction of additive processing, etc., can solve problems such as troublesome operation methods and market customer acceptance, and achieve the effects of reducing production costs, reducing manpower intensity, and improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

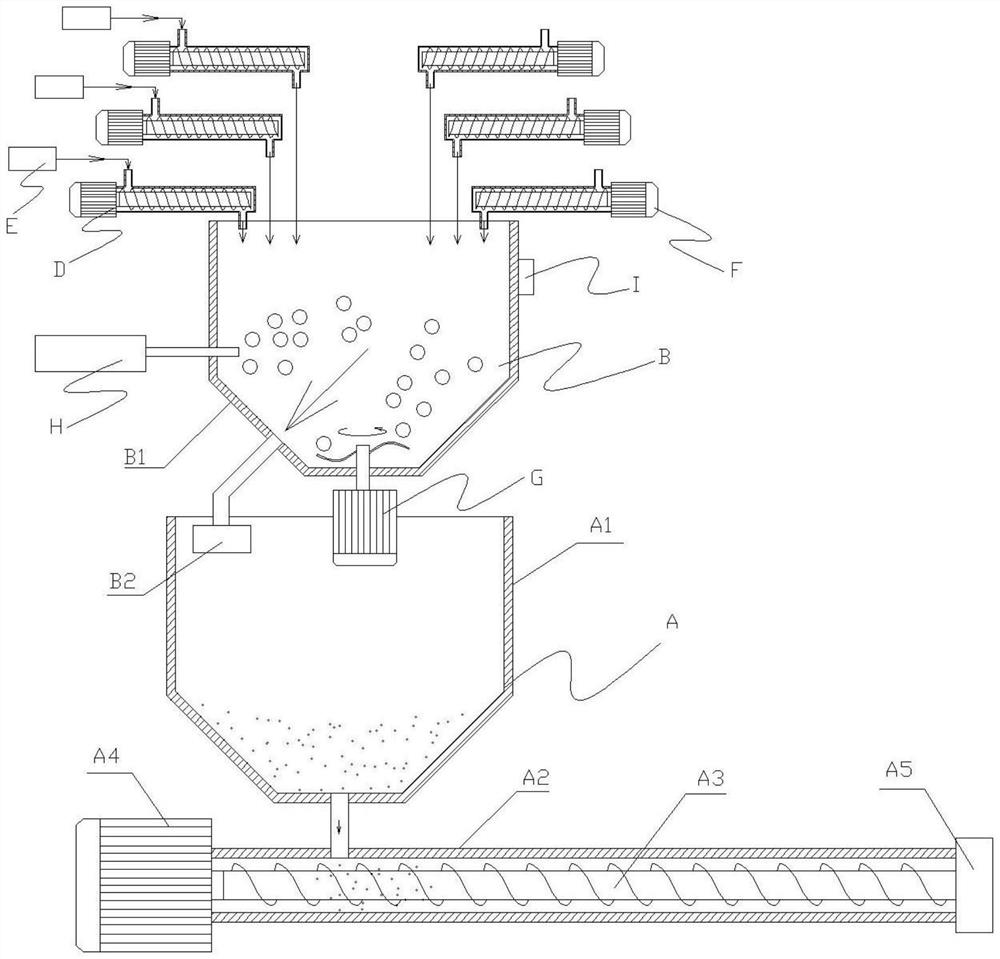

[0022] Such as Figure 1 to Figure 3 As shown, a kind of device of the present invention produces the 3D printing consumables of gradient color, and it comprises:

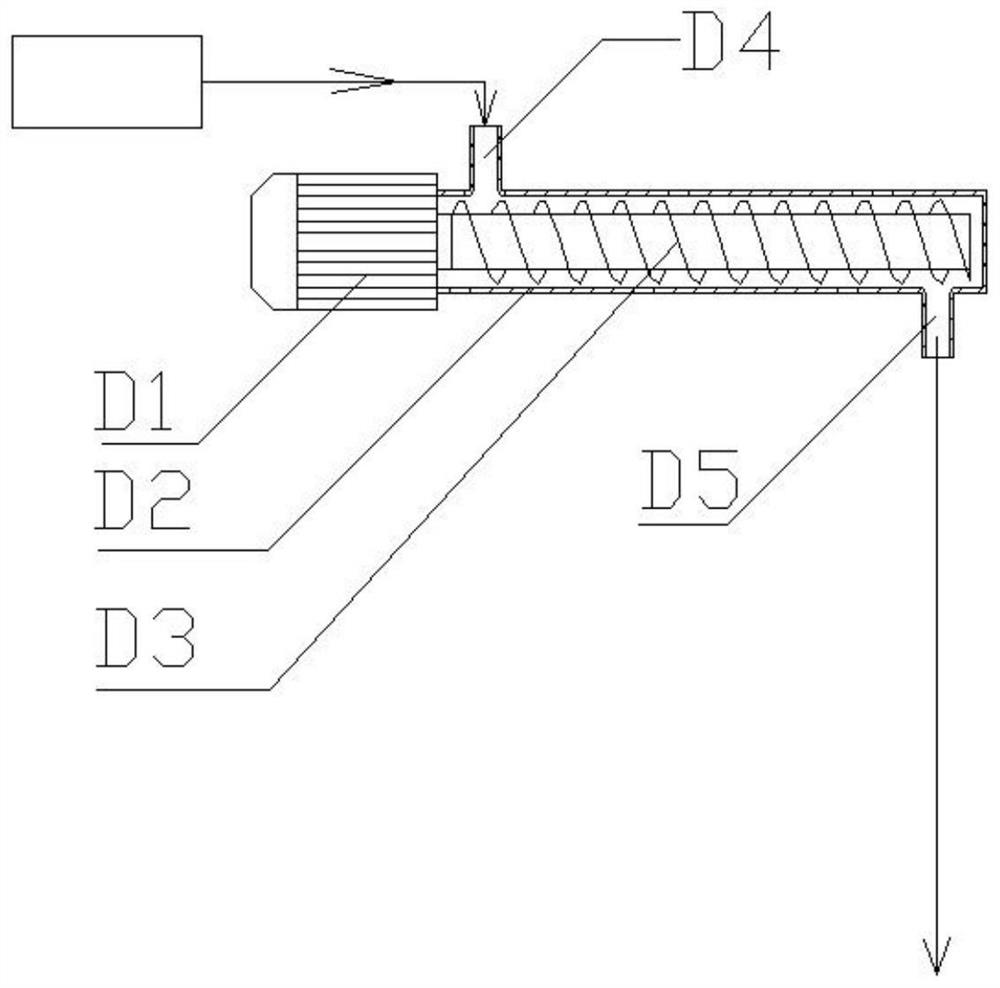

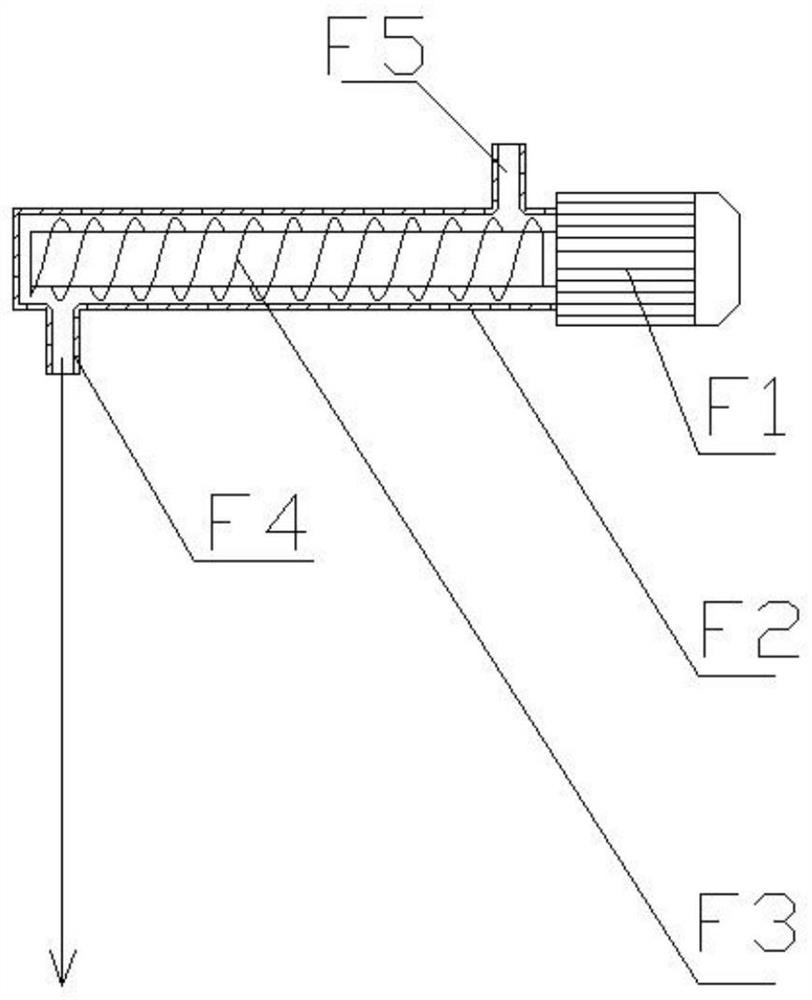

[0023] Extruder A, which includes a main hopper A1, a barrel A2, a first screw A3, a first motor A4 and a head A5; the first motor A4 is fixedly installed on one end of the barrel A2; the head A5 is installed on the barrel The other end of A2; the first screw rod A3 is located inside the barrel A2, and one end of the first screw rod A3 is connected to the first motor A4 in transmission; a mold is installed on the machine head A5; the inside of the main hopper A1 communicates with the inside of the barrel A2;

[0024] The mixing device B, which is arranged above the main hopper A1, includes a mixing hopper B1 arranged above the main hopper A1, a first electromagnetic valve B2 fixedly installed at the lower end of the mixing hopper B1 and connected to the inside of the mixing hopper B1;

[0025] The main material fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com