Supporting and reinforcing method for oblique beam and oblique column clear water curved surface special-shaped component

A technology of special-shaped components and slanted columns, which is applied in the field of erection of building support frames, can solve problems such as inadequate reinforcement of structures, impact on buildings, waste of materials, etc., and achieve the effects of good space structure, safe structure system, and convenient erection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

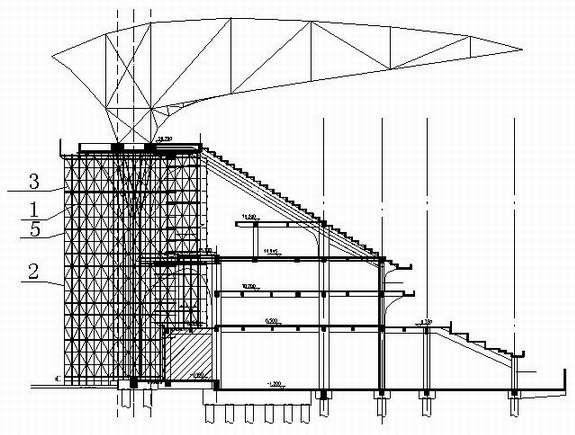

[0029] see now figure 1 with figure 2 , figure 1 It is a schematic diagram of the support and reinforcement system of the oblique beam clear water member of the embodiment of the present invention, figure 2 It is a schematic diagram of the support and reinforcement system of the slanted column clear water member of the embodiment of the present invention.

[0030] The method for supporting and reinforcing inclined beams and inclined columns with clear water curved surface special-shaped members of the present invention comprises the following steps:

[0031] a. Before erecting the support frame, complete the treatment of the support frame foundation. For the concrete structure floor, ensure that the structural surface is clean and tidy; for the natural foundation ground, it is necessary to pave gravel, and pour 150mmC20 concrete cushion on it;

[0032] b. Position and set out the wires on the base layer, pop out the pole positioning line of the support frame body, positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com