Harvester fan

A harvester and fan technology, which is applied to harvesters, machines/engines, agricultural machinery and implements, etc., can solve the problems of uneven air supply from fans and affecting the winnowing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

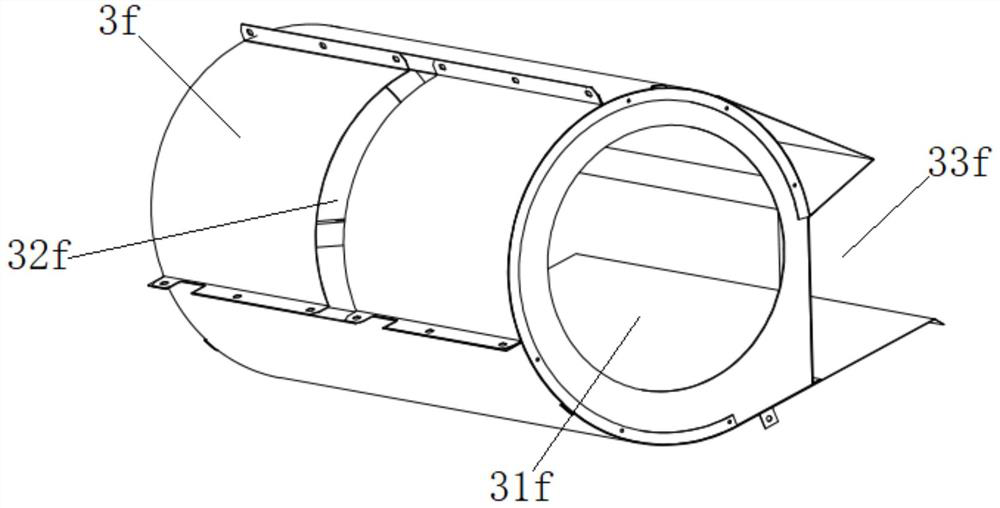

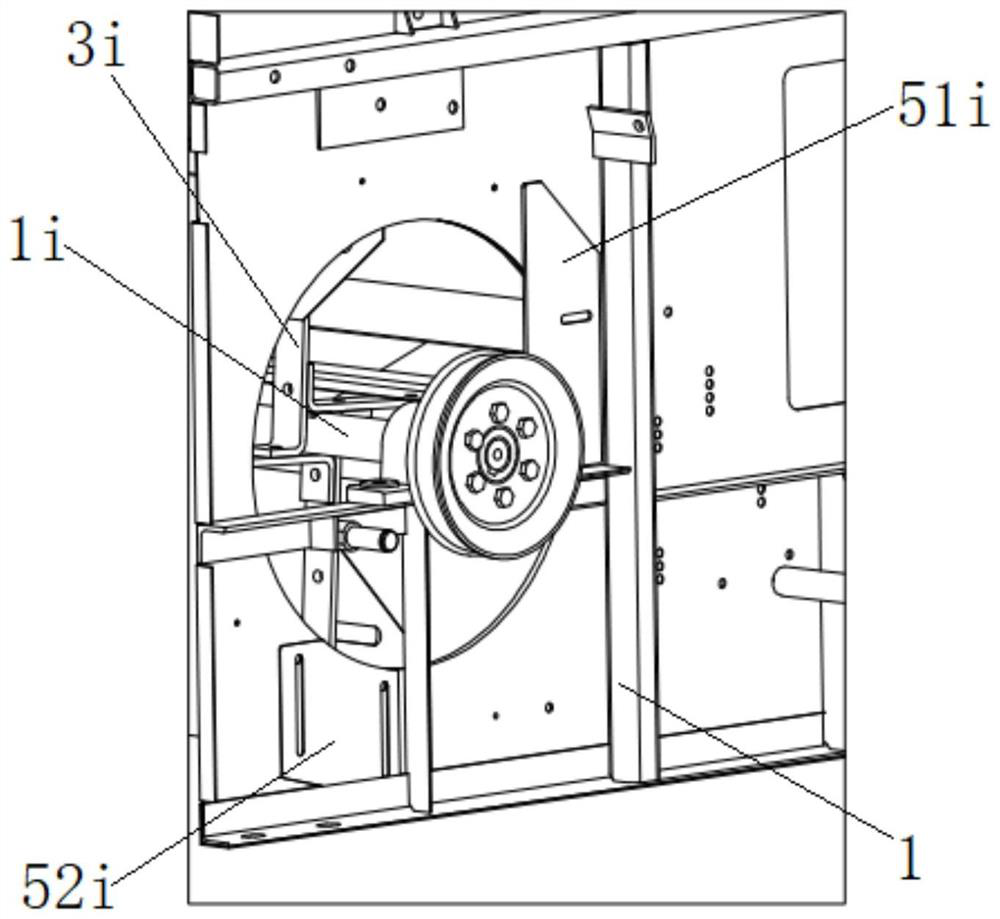

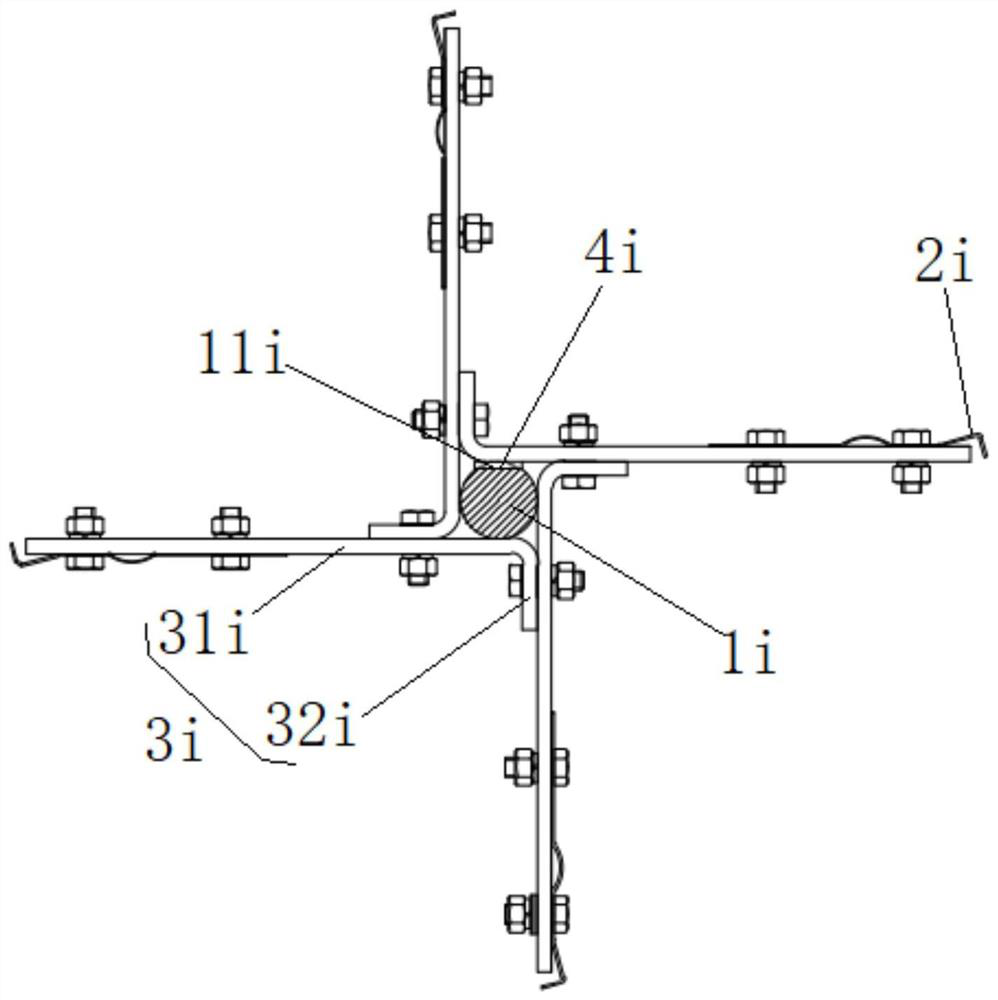

[0044] This embodiment provides a harvester fan, such as figure 1 and figure 2 As shown, it includes fan housing 3f, fan structure and fan drive.

[0045] The fan structure is installed in the cylindrical installation chamber of the fan housing 3f, and the two axial ends of the fan housing 3f are respectively provided with first air inlets 31f communicating with the outside world. The first air inlet 31f is a circular air inlet, concentric with the cross-section of the cylindrical installation cavity. An air outlet 33f is provided on the side wall of the fan housing 3f along its axial direction, and the width of the air outlet 33f is the same as that of the installation cavity. An air guide structure may be installed on the air outlet 33f, so as to guide the air to blow toward a set direction.

[0046] Such as figure 1 As shown, a second air inlet 32f is provided on the side wall of the fan housing 3f opposite to the air outlet 33f along the circumferential direction of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com