A rotary baking device for wire and cable production

A wire and cable, baking device technology, applied in the direction of drying, drying machine, progressive drying machine, etc., can solve the problems of incomplete and efficient baking, single structure of wire and cable baking, etc., to improve the quality of baking and Efficiency, improvement effect, effect of improving distribution uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

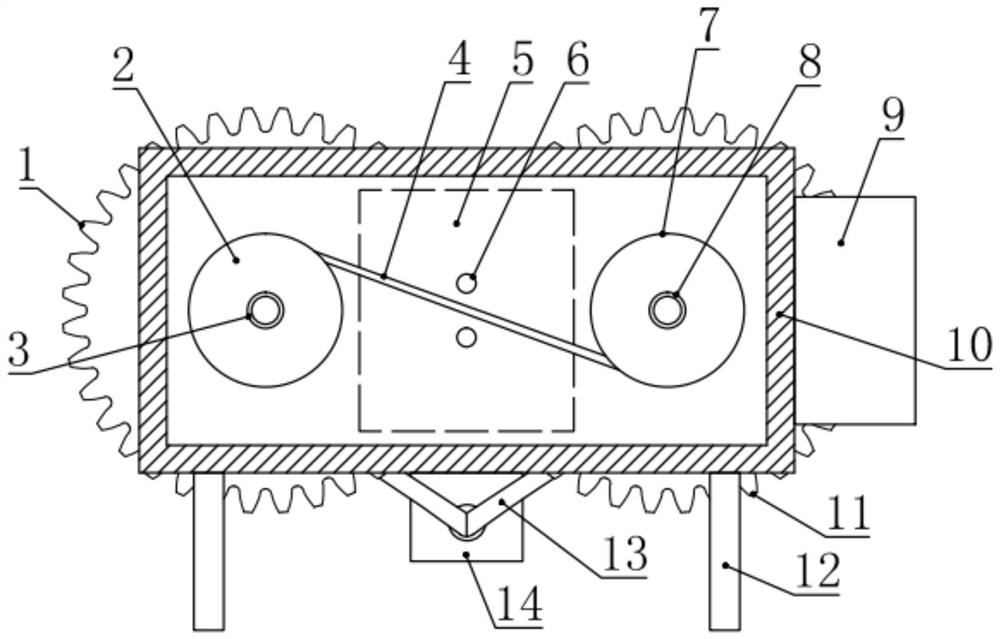

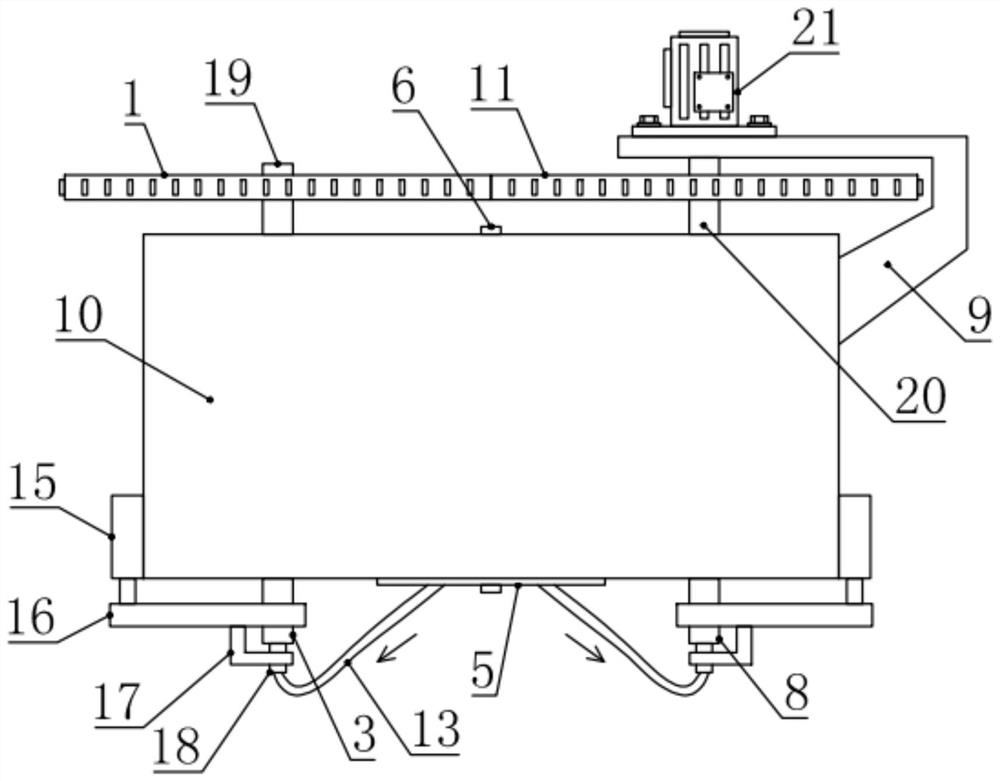

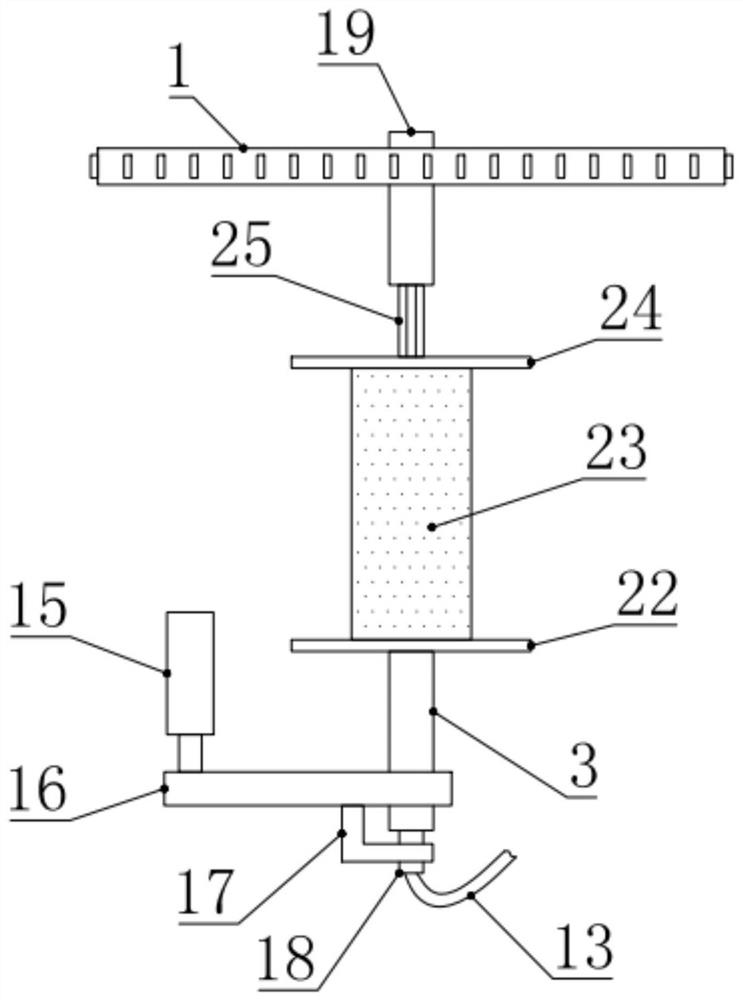

[0023] see Figure 1-3 , In the embodiment of the present invention, a rotary baking device for wire and cable production includes a baking box 10, the bottom of the baking box 10 is installed with support legs 12, and the support legs 12 can be used for the baking box. 10 for support, the left and right sides of the inside of the baking box 10 are respectively provided with a first winding assembly 2 and a second winding assembly 7, and the rear of the first winding assembly 2 and the second winding assembly 7 A pin 25 is installed and fixed at the ends respectively, and the two pins 25 are slidably connected with the first rotating pipe 19 and the second rotating pipe 20 respectively. The first rotating pipe 19 and the second rotating pipe The rear side wall is rotatably connected, and a drive mechanism for driving the first rotating tube 19 and the second rotating tube 20 to rotate in the opposite direction is also installed on the outside of the baking box 10. The first wi...

Embodiment 2

[0027] see Figure 1-4 , the difference between this embodiment and Embodiment 1 is:

[0028] In this embodiment, the structures of the first winding assembly 2 and the second winding assembly 7 are the same, and both the first winding assembly 2 and the second winding assembly 7 include a front baffle 22 and a winding net drum 23 . And the rear baffle 24, the described winding mesh cylinder 23 is a cylindrical mesh cylinder, and the front and rear ends of the winding mesh cylinder 23 are respectively installed and fixed with a front baffle 22 and a rear baffle 24, and through the winding mesh cylinder 23 The setting is favorable for the discharge of hot air, thereby improving the baking effect of the wire and cable 4 .

[0029] The first rotating pipe 19 and the second rotating pipe 20 are arranged horizontally and in parallel, one end of the plug 25 is fixed at the middle position of the rear baffle 24, and the cross section of the plug 25 is a regular polygon, which is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com