A device and method for cutting off non-effective test airflow in a shock tunnel

A shock tunnel and non-effective technology, which is applied in the field of devices to cut off the non-effective test air flow in the shock tunnel, can solve the problems of test model sensor scour damage, and achieve the effect of preventing scour damage

Active Publication Date: 2022-05-13

中国空气动力研究与发展中心超高速空气动力研究所

View PDF12 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Generally speaking, the pressure of the high-pressure driving gas is tens or even hundreds of times that of the low-pressure test gas, and a large amount of high-pressure driving gas entering the test section can easily cause erosion damage to the test model sensor

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0035] The working process of the device and method for cutting off the non-effective test airflow in the shock tunnel of the present invention is as follows:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

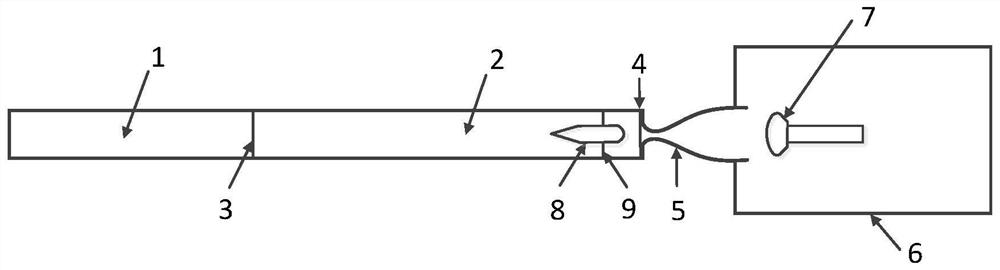

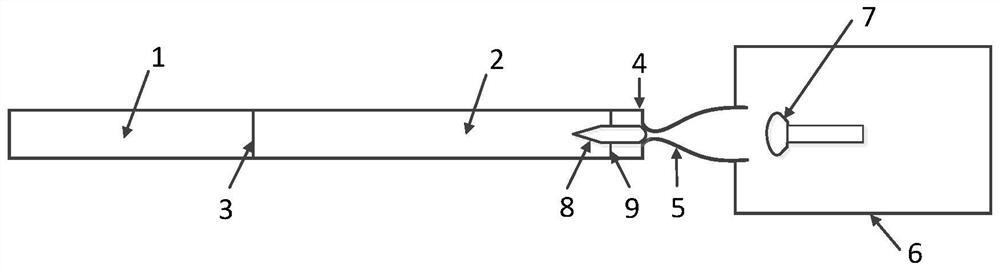

The invention discloses a device and method for cutting off ineffective test air flow in a shock wave wind tunnel. The device adds a central valve body with a delay function in the conventional shock wave wind tunnel. The central valve body is installed in the rear section of the driven section and in front of the nozzle inlet. The effective test gas flow of the central valve body is not in the driven section. It is in the open state before the end, and when the effective test gas flows out and the test data collection is completed, the central valve body moves to the closed state. The method can seal the high-pressure driving gas in the driving section in the shock tube through the movement of the central valve body, cut off the non-effective test air flow from entering the test section, and prevent the scouring damage of the test model sensor caused by a large amount of residual gas entering the test section.

Description

technical field [0001] The invention belongs to the technical field of shock wave wind tunnels, and in particular relates to a device and method for cutting off ineffective test air flow in shock wave wind tunnels. Background technique [0002] The shock tunnel / shock tube is a test device that generates high temperature and high pressure airflow. Because the shock tube can easily heat, pressurize and accelerate the gas to a very high parameter, it is widely used in aerospace, aviation, explosion engineering, chemistry and physics and other fields. [0003] The shock tube of a conventional shock tunnel consists of two sections, separated by a main diaphragm, and the two sides of the main diaphragm are filled with gases of different pressures; the front section with higher pressure is called the high pressure section, also known as It is the driving section, and the driving section is filled with high-pressure driving gas; the latter section with lower pressure is called the ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01M9/04

CPCG01M9/04

Inventor 李贤廖振洋钟涌孔小平吴里银孔荣宗常雨张扣立

Owner 中国空气动力研究与发展中心超高速空气动力研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com