A method and device for intelligently regulating the fermentation quality of black tea in real time using Raman scanning

A Raman scanning and fermentation device technology, applied in the field of tea fermentation, can solve the problems of regulation, low speed, and inability to carry out process parameters, and achieve the effects of compact and simple structure, controllability and high effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

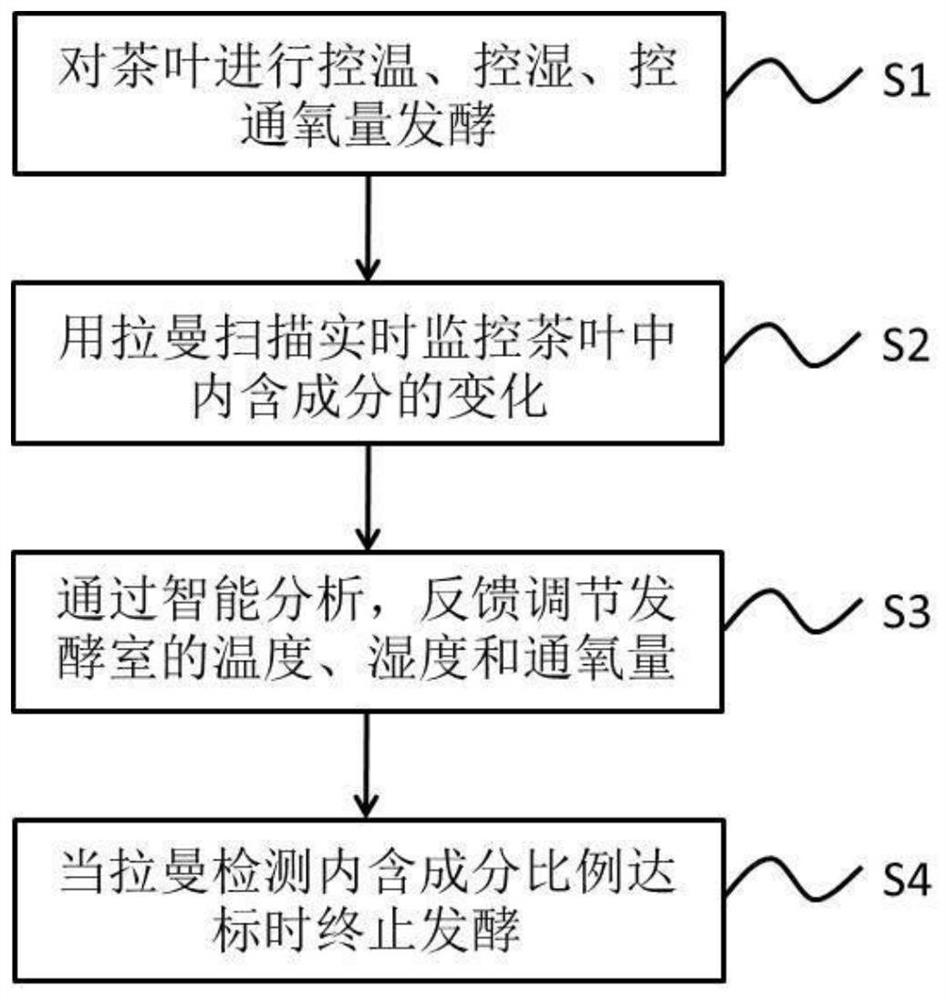

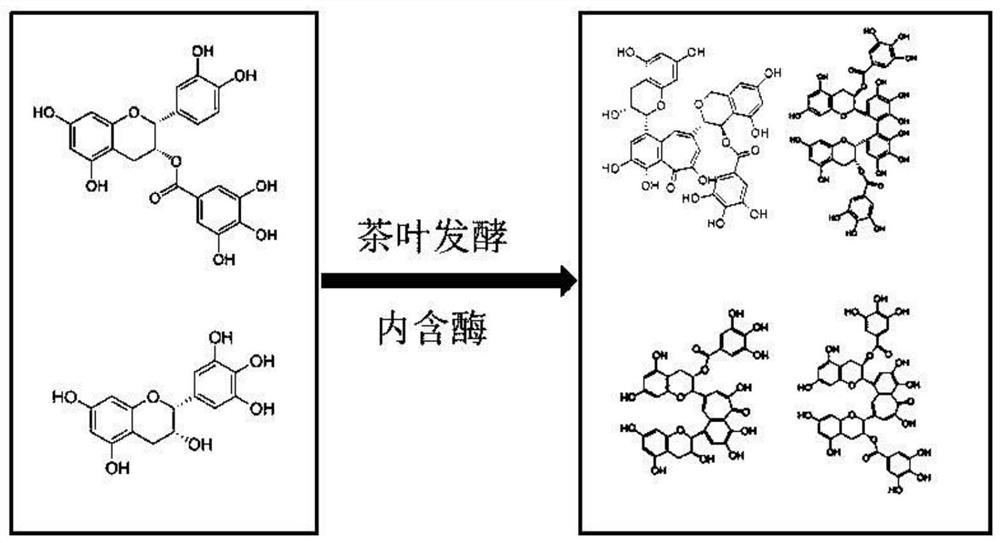

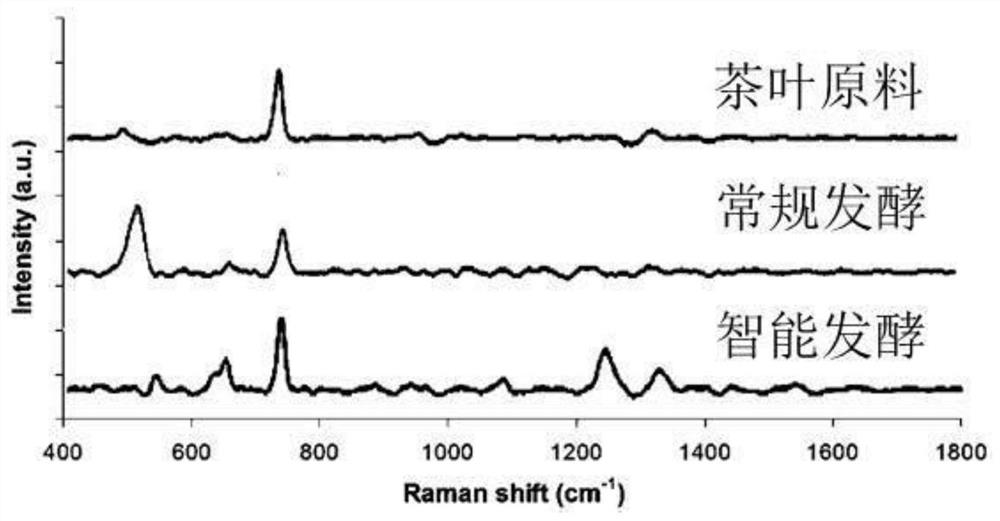

[0044] The present embodiment provides a method for intelligently controlling the fermentation quality of black tea in real time by applying Raman scanning, which is characterized in that the components of the raw tea leaves used for black tea fermentation and the changes of the components contained in the tea leaves during the fermentation process are all monitored in real time by Raman scanning spectroscopy. Tea leaves contain C-C-O deformed bonds at 450-550cm-1 and 620-680cm-1 Raman characteristic peaks of chemical functional groups of catechins, theaflavins, thearubigins and polyester catechins, 720-750cm- 1 The C-H pull bond at the Raman characteristic peak, the C-O diester pull bond at the 1230-1280cm-1 Raman characteristic peak, and the benzene ring vibration bond at the 1330-1380cm-1 Raman characteristic peak, and according to the Raman Scan the data to analyze the deviation of the fermentation direction, and adjust the temperature (20-35 degrees Celsius), relative humi...

Embodiment 2

[0055] The present embodiment provides a method for applying Raman scanning to intelligently control the fermentation quality of black tea in real time. The black tea fermentation process is as follows:

[0056] S1: The spring harvested tea leaves from the tea plantation in Liping, Shimen County, Hunan Province are used as fermentation raw materials, and the tea leaves are fermented with temperature control, humidity control, and oxygen supply control. The initial fermentation temperature is 30 degrees Celsius, relative humidity 90%, and oxygen supply 4L. / kg tea;

[0057] S2: Raman scanning was used to monitor the changes of components in tea leaves in real time, and it was found that the content of polyester catechins increased rapidly on the second day of fermentation;

[0058]S3: Through intelligent analysis, the conventional fermentation of the reference group is not processed; for the intelligent fermentation group, feedback adjustment is performed, the temperature of th...

Embodiment 3

[0064] The present embodiment provides a real-time intelligent control method of black tea fermentation quality using Raman scanning, and the black tea fermentation process is as follows:

[0065] S1: The tea harvested in summer from the tea plantation in Liping, Shimen County, Hunan Province is used as the fermentation raw material, and the tea leaves are fermented with temperature control, humidity control, and oxygen control. The initial fermentation temperature is 30 degrees Celsius, relative humidity 90%, and oxygen supply 4L / kg of tea leaves;

[0066] S2: Raman scanning was used to monitor the changes of the components contained in tea leaves in real time, and it was found that the content of polyester catechins increased rapidly at the beginning of fermentation, while the content of thea yellow / rubin substances did not increase significantly;

[0067] S3: Through intelligent analysis, for the conventional fermentation of the reference group, reduce the temperature of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com