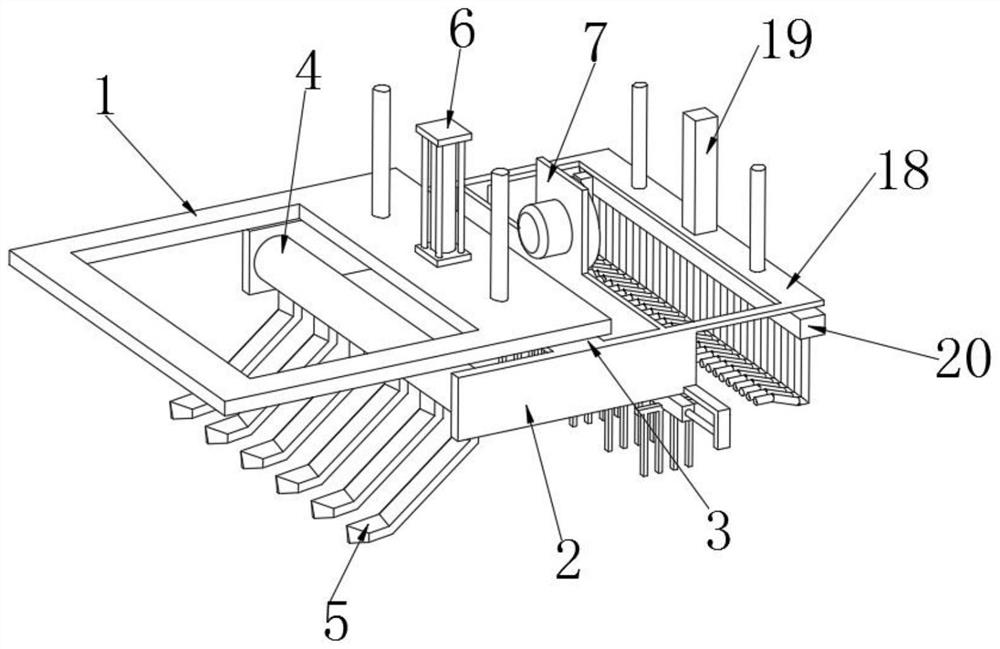

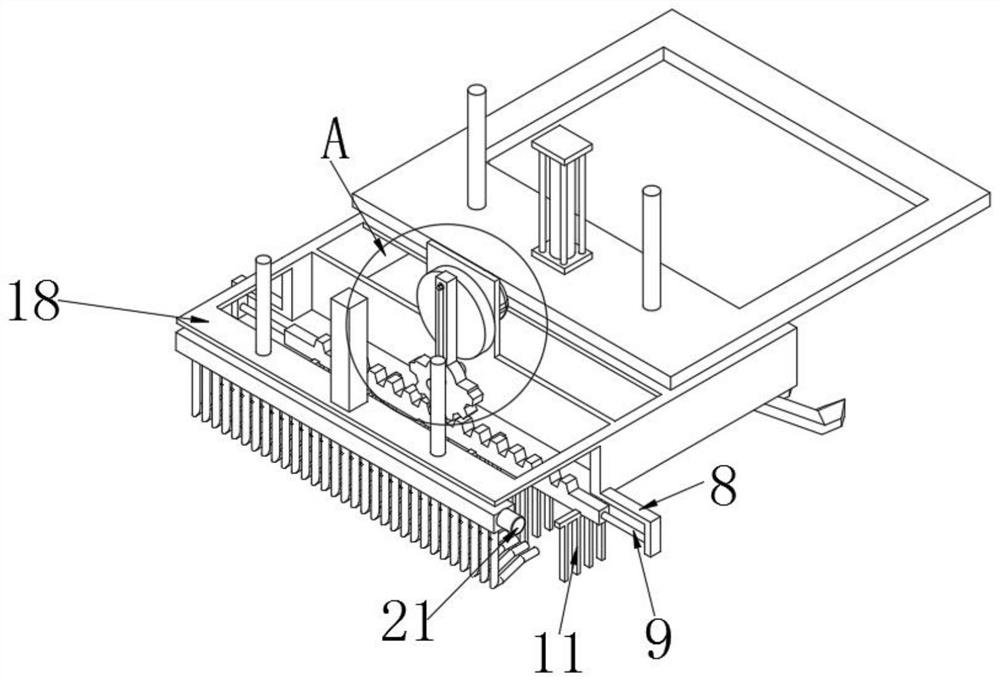

Soil turning device for crop planting and working method thereof

A crop and activity installation technology, applied in the field of soil turning devices for crop planting, can solve problems such as difficulty in planting crops, manual removal, and inability to break up clods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

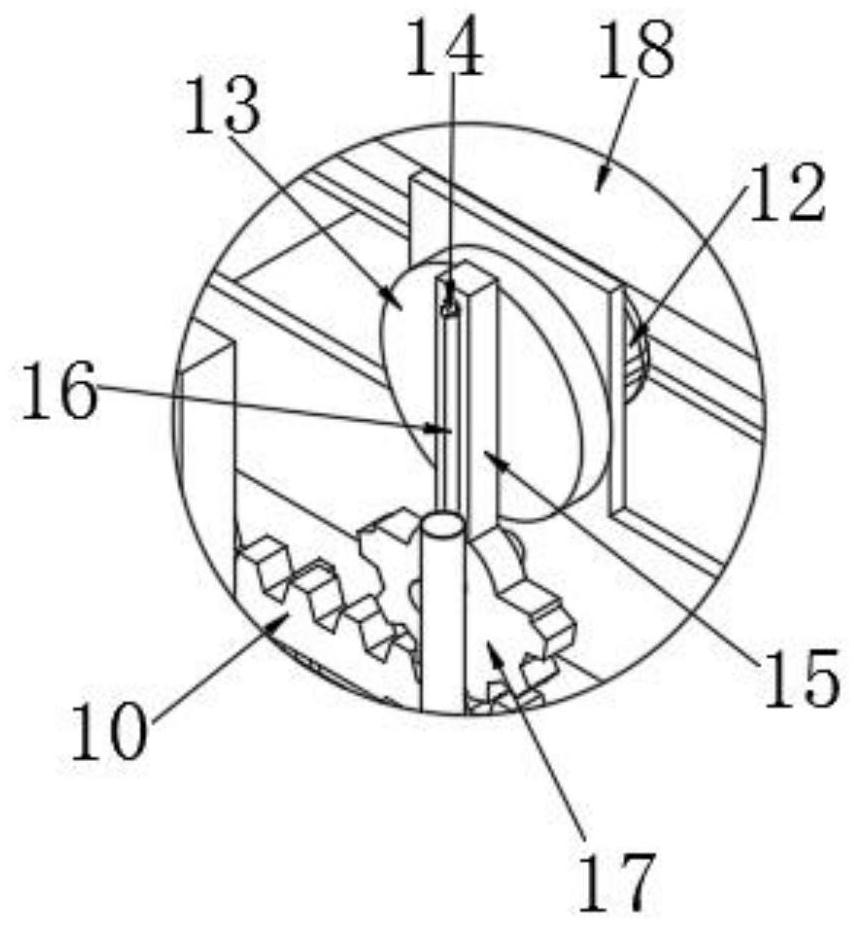

[0032] As an embodiment of the present invention, a first servo motor 12 is installed on the top side of the T-shaped plate 7, and the output end of the first servo motor 12 is installed through the T-shaped plate 7. A turntable 13 is installed, and a limit rod 14 is arranged on the outer side of the turntable 13. And the stop bar 14 outsides are equipped with rollers, the T-shaped plate 7 other side is rotated and installed with a half tooth 17, and the center of the half-tooth 17 is connected with the T-shaped plate 7 by a plug shaft, and the half-tooth 17 meshes with the rack 10, and A support rod 15 is installed in the middle part of the top of the half tooth 17, and a chute 16 is provided on the outside of the support rod 15, and the roller and the inner wall of the chute 16 are rolled and installed. The first servo motor 12 on the T-shaped plate 7 works to drive the turntable 13 to rotate, and the turntable 13 Rotating through the roller on the limit rod 14 rolls on the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com