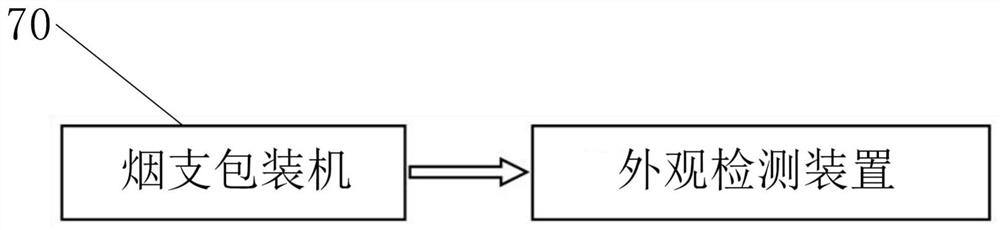

Combined detection device for cigarette packets

A combined detection and detection device technology, applied in sorting and other directions, can solve problems such as downstream equipment blockage, equipment mechanism displacement, fracture damage, etc., and achieve the effect of improving efficiency and accurate appearance inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

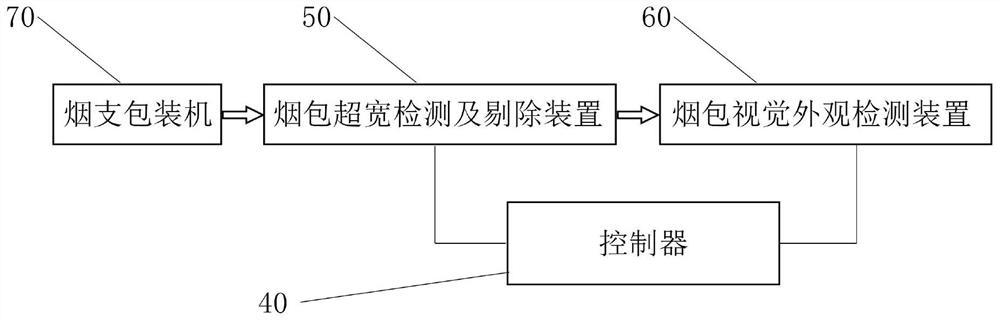

[0042] Embodiment 1 of the present invention provides a cigarette packet combination detection device, which includes a cigarette packet ultra-wide detection and rejection device 50 , a cigarette packet visual appearance detection device 60 and a controller 40 .

[0043] The cigarette pack ultra-wide detection and rejecting device 50 is arranged downstream of the cigarette packaging machine 70 , and the cigarette pack ultra-wide detection and rejecting device 50 is arranged upstream of the cigarette pack visual appearance inspection device 60 .

[0044] The cigarette pack ultra-wide detection and rejection device 50 and the cigarette pack visual appearance detection device 60 are respectively electrically connected to the controller 40 .

[0045] Conveyance channels are provided between the cigarette packaging machine 70 and the cigarette pack ultra-wide detection and rejection device 50 , and between the cigarette pack super-width detection and rejection device 50 and the ciga...

Embodiment 2

[0060] The difference between this embodiment and Embodiment 1 is:

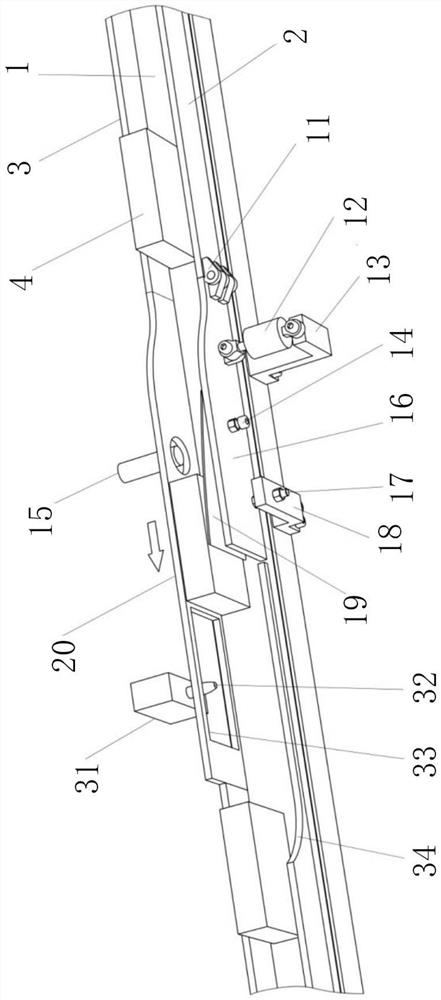

[0061] The cigarette packet ultra-wide detection and rejecting device 50 provided by the embodiment of the present invention includes a conveyor belt 1, a first blocking plate 20, a movable blocking plate assembly, a blocking sensor 15 and a rejecting mechanism.

[0062] The conveyor belt 1, the first blocking plate 20, and the movable blocking plate assembly jointly form an ultra-wide blocking channel. A rejecting mechanism is arranged downstream of the ultra-wide blocking channel. The probe of the obstruction sensor 15 points to the ultra-wide obstruction channel.

[0063] The controller 40 is electrically connected to the blockage sensor 15, and is used for judging whether the ultra-wide blocking channel is blocked. The controller 40 also connects and controls the movable blocking plate assembly, the conveyor belt 1 and the rejecting mechanism respectively.

[0064] The first blocking plate 20 is matche...

Embodiment 3

[0069] The differences between this embodiment and embodiment two are:

[0070] A first guide rod 2 and a second guide rod 3 are provided upstream of the ultra-wide blocking passage, and the first guide rod 2 and the second guide rod 3 are respectively on both sides of the conveyor belt 1 upstream of the ultra-wide blocking passage. The conveyor belt 1 , the first guide rod 2 and the second guide rod 3 are jointly surrounded to form a conveying channel, which communicates with the ultra-wide blocking channel, and the conveying channel is used for transporting cigarette packs.

[0071] The movable blocking plate assembly includes a blocking piece 19, a second movable blocking plate and a driving device. The second movable blocking plate is connected to the blocking piece 19, and the blocking piece 19 is arranged on the inner side of the second movable blocking plate. The controller 40 controls the position of the movable second blocking plate through the driving device. The mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com