Light-emitting automobile sign and production process thereof

A technology for automobile signs and production technology, which is applied to optical signals, vehicle parts, signal devices, etc., can solve the problems of low pass rate of luminous automobile signs, achieve the effect of ensuring the appearance surface quality, high structural strength, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

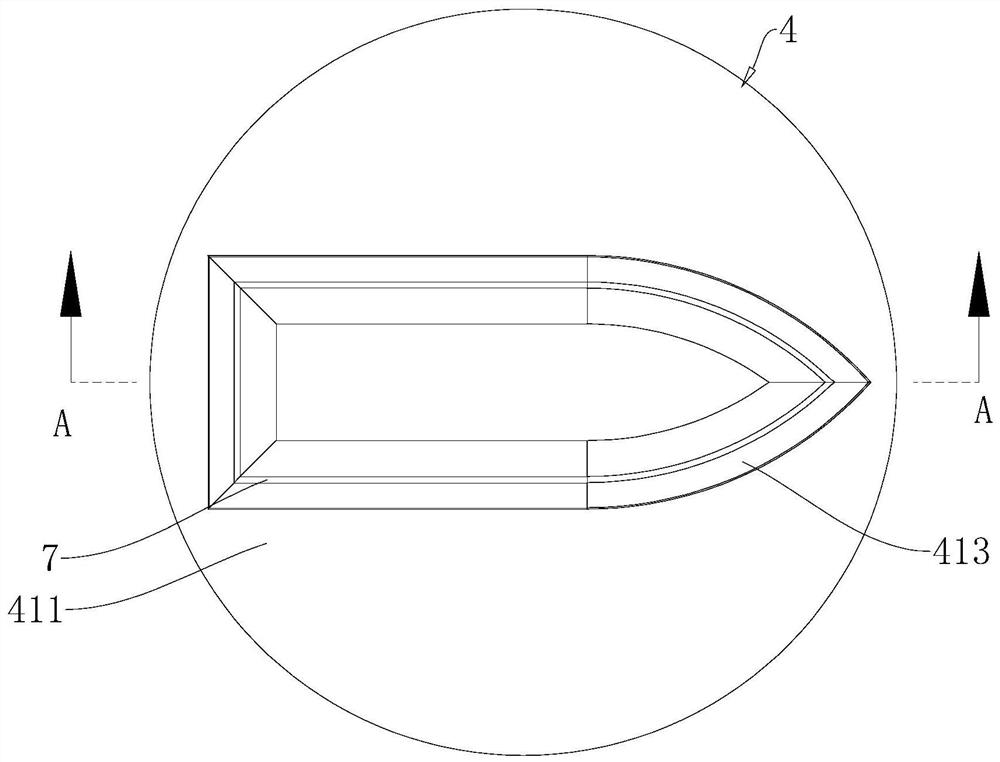

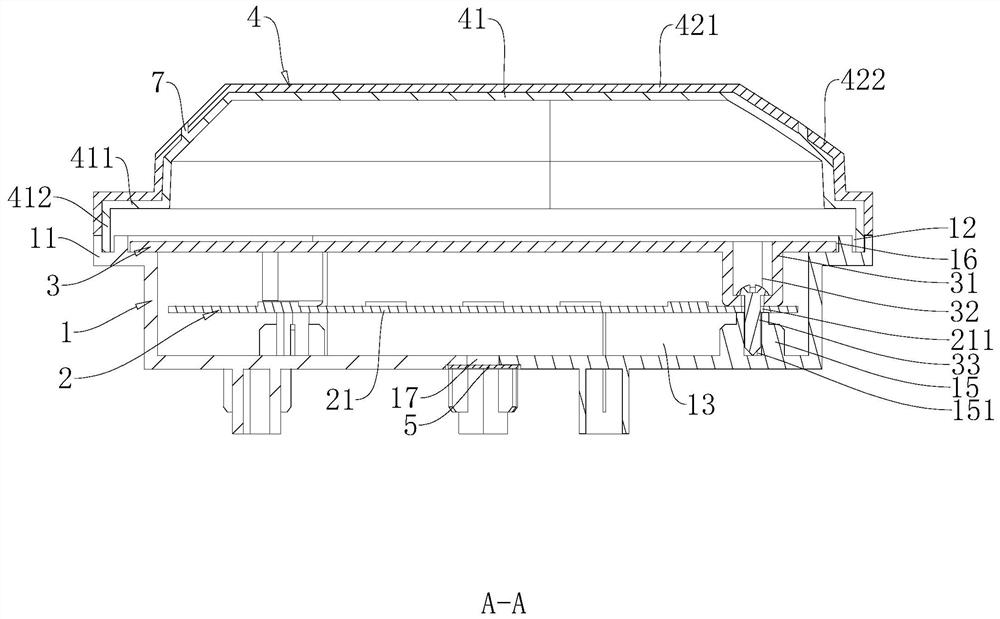

[0048] refer to figure 1 and figure 2 , The luminous automobile signboard includes a signboard base 1 , a light source part 2 , a uniform light plate 3 and a sign cover 4 .

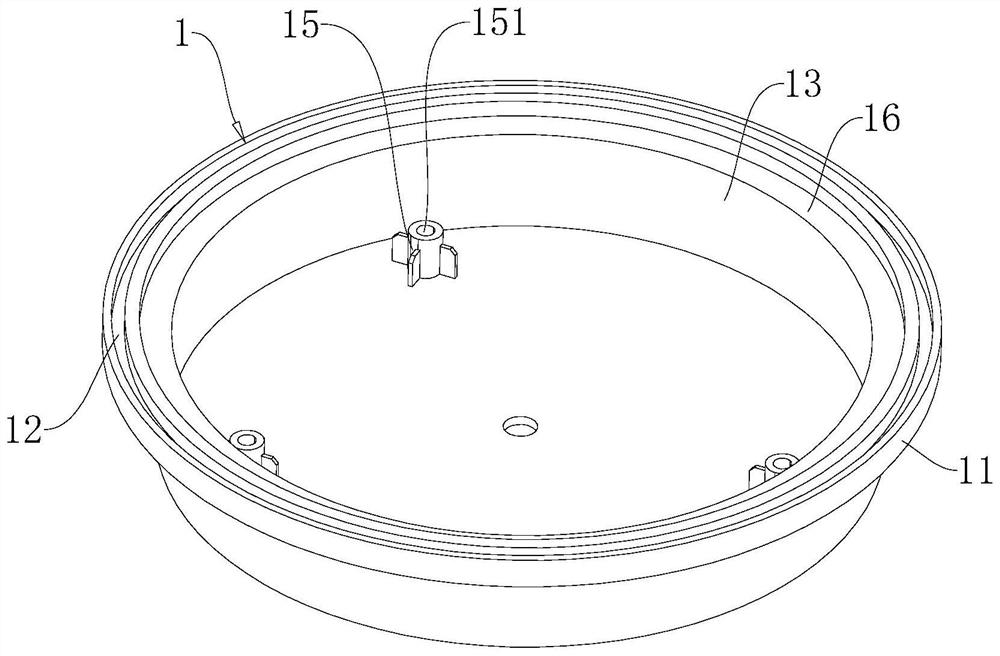

[0049] refer to figure 2 and image 3 , The sign base 1 is a hollow and cylindrical plastic seat. The sign base 1 is coaxially provided with an installation ring 11 for installing the sign cover 4 at the end close to the sign cover 4 . The mounting ring portion 11 is provided with a mounting ring groove 12 in the circumferential direction of the end surface facing the sign cover 4 .

[0050] refer to image 3 , The sign base 1 has a cylindrical installation cavity 13 . The installation cavity 13 is formed with an installation opening on the end surface of the sign base 1 close to the sign. The sign base 1 is vertically provided with three installation columns 15 on the bottom surface of the installation cavity 13 . The three installation columns 15 are evenly arranged around the axis of the sign...

Embodiment 2

[0067] refer to Figure 7 , this embodiment also discloses a luminous automobile signboard, which is different from the implementation of Example 1 in that: the outer surface 612 of the first outer cover of the first sign outer cover 421 is not provided with sign coating, and the outer surface of the second sign The outer surface 621 of the second outer cover of the cover 422 is not provided with logo coating, and the connection method between the logo outer cover and the transparent bottom cover 41 is not through laser transmission welding.

[0068] In this embodiment, the logo cover 4 is directly produced by a two-color injection machine, and the logo outer cover is fixed on the outer surface of the transparent bottom cover 41 during the production process.

Embodiment 3

[0070] refer to Figure 8 , this embodiment also discloses a luminous car sign, which is different from the embodiment of Example 1 in that: the position of the installation ring groove 12 in the sign base 1 and the installation flange of the sign base 1 and the transparent bottom cover 41 412 fixed way.

[0071] In this embodiment, the installation ring groove 12 of the signage base 1 is arranged at the edge of the end surface of the installation ring portion 11 facing the sign cover 4 . The installation flange 412 of the transparent bottom cover 41 can be inserted into the installation ring groove 12 , and the inner side wall of the installation flange 412 is attached to the annular side wall 121 of the installation ring groove 12 . Since the transparent bottom cover 41 is made of transparent PC and the sign base 1 is made of black PC, the installation flange 412 of the transparent bottom cover 41 and the annular side wall 121 of the installation ring groove 12 are connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com