Intelligent shoe cabinet

A shoe cabinet, intelligent technology, applied in the cleaning of cabinets, wardrobes, boots and shoes, etc., can solve the problem that the integrated function of cleaning, maintenance, storage, transportation and taking out shoes cannot be realized, the shoe cabinet does not automatically release shoes, and the interior of the automatic storage is automatic. Problems such as transmission and poor experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

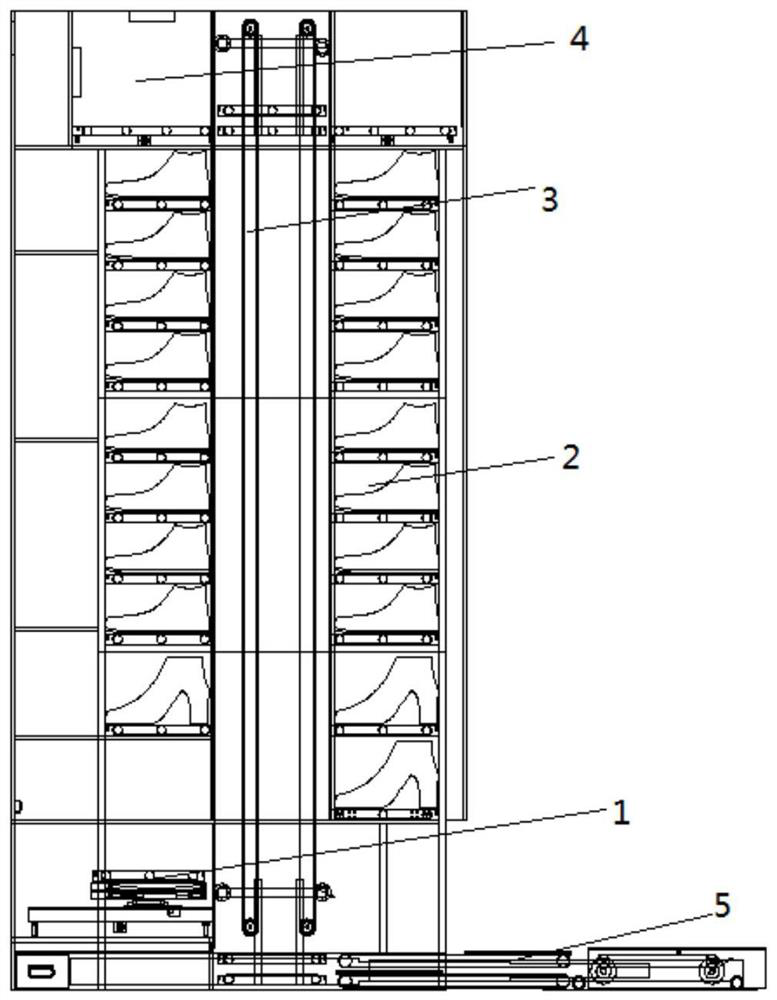

[0097] like Figure 10 As shown, in the first embodiment, the console 11 is specifically an assembly of the console 11 that integrates the functions of lifting, rotating, and translating, and specifically includes a horizontal transmission mechanism 111, a lifting mechanism 112, a rotating mechanism 113, and a horizontal sliding mechanism. Shifting mechanism 114 and longitudinal sliding mechanism 115. Wherein, the horizontal transmission mechanism 111 is used for moving the shoes to be cleaned in the horizontal direction, and the longitudinal sliding mechanism 115 is used to drive the shoes to be cleaned to move in the vertical direction, and the vertical sliding mechanism 115 is located below the horizontal transmission mechanism 111 . A lifting mechanism 112 , a rotating mechanism 113 and a lateral sliding mechanism 114 are arranged in sequence from top to bottom between the horizontal transmission mechanism 111 and the longitudinal sliding mechanism 115 . The lifting mecha...

Embodiment 2

[0106] like Figure 11 As shown, in the second embodiment, the console 11 uses a horizontal transmission mechanism 111 and a liftable vertical transmission mechanism 1113 to realize the delivery of shoes. Unlike the horizontal transmission mechanism 111 in the first embodiment, this implementation The horizontal transfer mechanism 111 in the example is provided with a plurality of cleaning rollers 1111 arranged side by side and a cleaning roller motor 1112 corresponding to the cleaning rollers 1111. The cleaning roller motor 1112 is used to drive the cleaning roller 1111 to rotate; the longitudinal transfer mechanism 1113 is specifically A vertical conveyor belt mechanism or a slide bar mechanism that can be lifted, and the vertical conveyor belt mechanism or the slide bar mechanism is connected with a jacking mechanism, and the jacking mechanism is used to lift the vertical conveyor belt mechanism or the slide bar mechanism so as to push the shoes to be cleaned away from the c...

Embodiment 3

[0110] like Figure 12 As shown, in the third embodiment, the cleaning chamber 10 is provided with a plurality of second manipulators 12211 fixed by the second base 12212. The second manipulators 12211 have multi-dimensional mobility, and the second manipulators 12211 can adopt industrial six-axis The mechanical arm can deliver the cleaning head 121 to any place on the outer surface of the shoe to realize the cleaning operation.

[0111] The console 11 adopts a combined structure of a horizontal transmission mechanism 111 and a vertical sliding mechanism 115, wherein the horizontal transmission mechanism 111 is specifically a conveyor belt mechanism, and the structure of the conveyor belt mechanism can refer to the conveyor belt mechanism in the first embodiment; The arrangement of the mechanism 115 can also refer to the longitudinal sliding mechanism 115 in the first embodiment. The horizontal transmission mechanism 111 is arranged above the longitudinal sliding mechanism 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com