Channel sealing valve, channel sealing mechanism and omnipotent hysteroscope

A sealing mechanism and hysteroscope technology, applied in the field of hysteroscopy, can solve problems such as liquid leakage, hysteroscope cannot be used normally, intrauterine pressure reduction, etc., and achieve the effect of preventing liquid leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

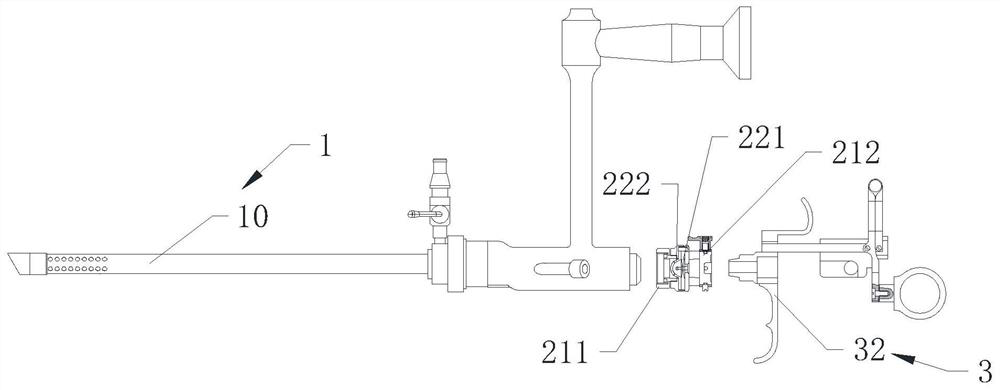

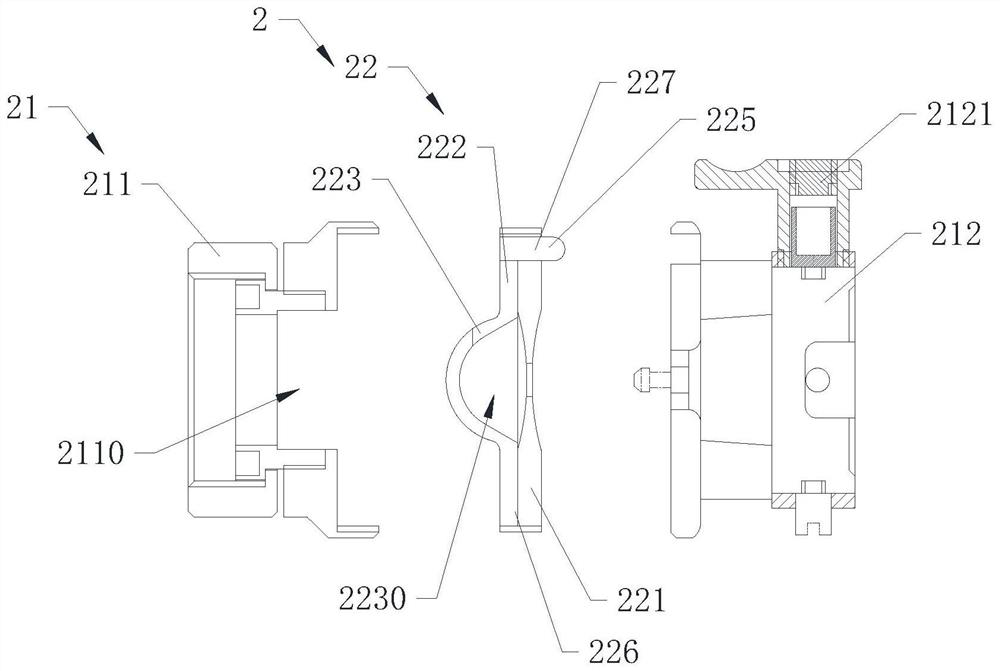

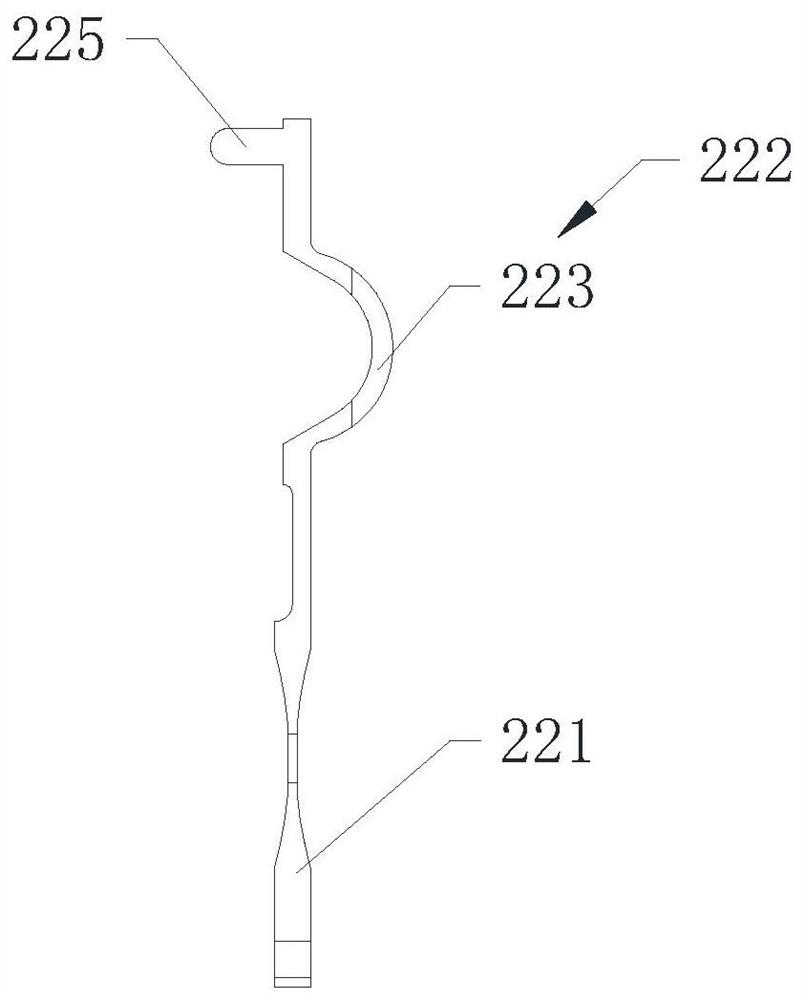

[0044] Reference manual attached Figure 1 to Figure 4 , the omnipotent hysteroscope provided by the present invention is described, and the channel sealing mechanism of the omnipotent hysteroscope provided by the present invention can be better when the working instrument 3 passes through, the working instrument 3 is replaced, and the working instrument 3 is missing. Reduce the outflow of liquid in the working pipeline, and keep the liquid pressure in the working pipeline in the range of 80-120mmHg during the use of the hysteroscope.

[0045] Reference manual attached figure 1 and figure 2, The omnipotent hysteroscope provided by the present invention includes a hysteroscope main body 1 , a channel sealing mechanism 2 and a working instrument 3 . The hysteroscope main body 1 has a working pipeline 10; the working instrument 3 includes an instrument body and a working hand piece 32, and the working hand piece 32 is installed on the instrument body; the channel sealing mecha...

Embodiment 2

[0073] Reference manual attached Figure 5 The second preferred embodiment of the channel sealing mechanism of the omnipotent hysteroscope provided by the present invention is described. The difference between the channel sealing mechanism of the omnipotent hysteroscope of the second preferred embodiment and the above-mentioned preferred embodiment is that , in the second preferred embodiment, further comprising a sleeve assembly installed on the working instrument 3, the sleeve assembly can prevent the working instrument 3 from The head end of 3 is in contact with the channel sealing mechanism 2, so that the head end of the relatively delicate working instrument 3 can be protected.

[0074] Reference manual attached Figure 5, specifically, the omnipotent hysteroscope further includes a sleeve assembly 4, and the sleeve assembly 4 is adapted to be installed on the instrument body 31 of the working instrument 3 for 31 provides protection for the head end of the instrument bo...

Embodiment 3

[0090] According to another aspect of the present invention, the present invention further provides a channel sealing method for the omnipotent hysteroscope, comprising:

[0091] During the process of inserting the working instrument 3 into the working pipeline 10, the elastic member 42 is pushed through the first locking part 51 of the working instrument 3 to drive the sleeve 41 located outside the working instrument 3 to move through together. channel sealing mechanism 2, and when the head end of the sleeve 41 passes through the channel sealing mechanism 2, the head end of the working instrument 3 is located in the sleeve 41; wherein the channel sealing mechanism 2 Located in the working pipeline 10;

[0092] When the head end of the sleeve 41 passes through the opening 20 of the sealing member 42 and moves a predetermined distance, it contacts the second locking part 52 installed in the working pipeline 10, allowing the working The instrument 3 continues to move forward re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com