Equipment used for spraying paint film on frosted wood stair stand column

A technology for columns and stairs, which is applied in the field of equipment for spraying paint film after wooden stair columns are sanded. It can solve the problems of inability to perform full grinding and painting, low work efficiency, and affecting the effect of painting, so as to achieve convenient grinding and painting work and convenient discharge Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

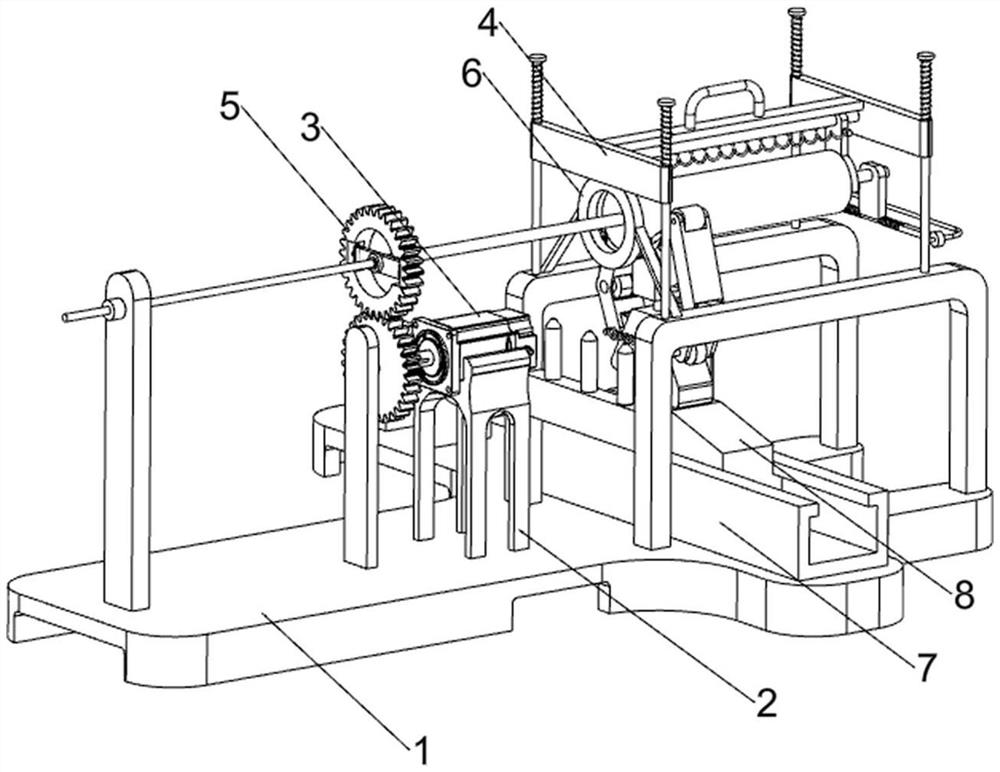

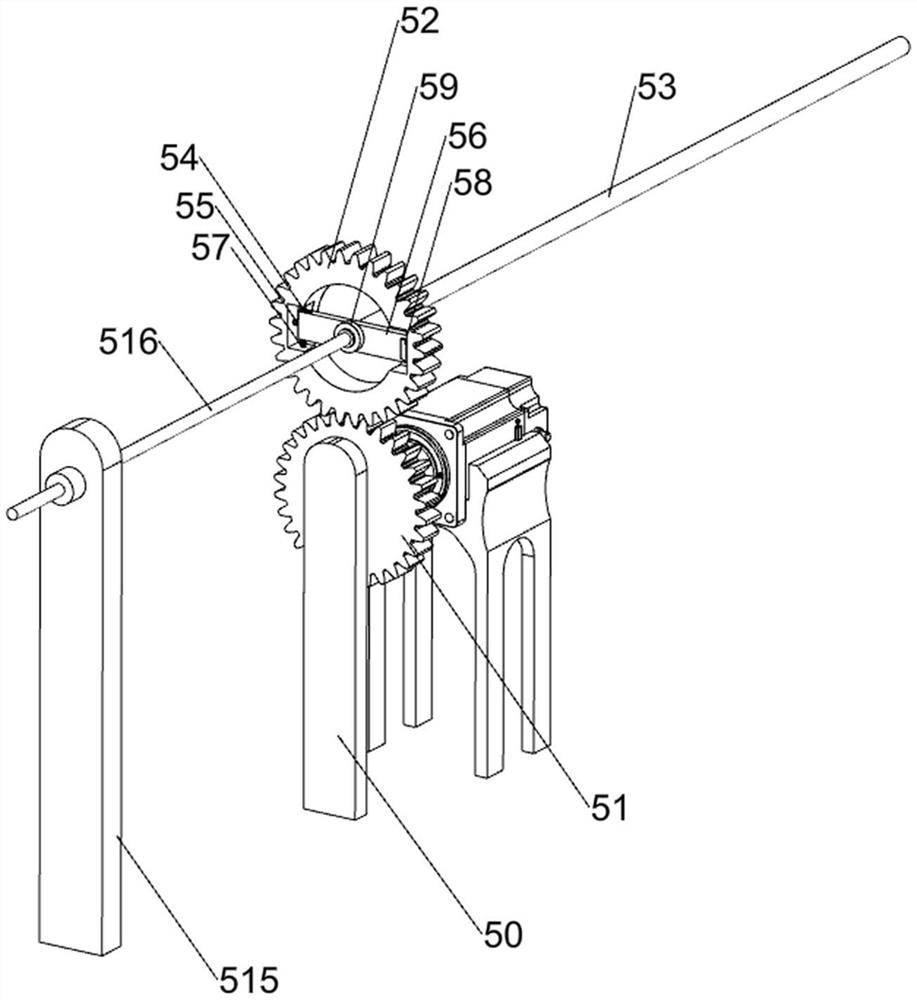

[0085]Apparatus for spraying film after wood stair column matte, such asfigure 1 As shown, including the base 1, the first support frame 2, the servo motor 3, the connecting mechanism 4, the rotating mechanism 5, the placing plate 9 and the spray gun 10, and the top left side of the base 1 is provided with a first support frame 2, and the first support. A servo motor 3 is provided at the top of the frame 2, and a connecting mechanism 4 is provided at the top of the base 1, and a rotating mechanism 5 is provided between the connecting mechanism 4 and the servo motor 3. There is a placing plate 9 in the connecting mechanism 4, and there are more placing plates 9. Spray gun 10.

[0086]The staff placed the column in the rotating mechanism 5, then pulled the connecting mechanism 4 so that the connecting mechanism 4 drive the column to drive the left, then activate the servo motor 3, the servo motor 3 drives the rotating mechanism 5 to rotate, and polished the rotation column At the same ti...

Embodiment 2

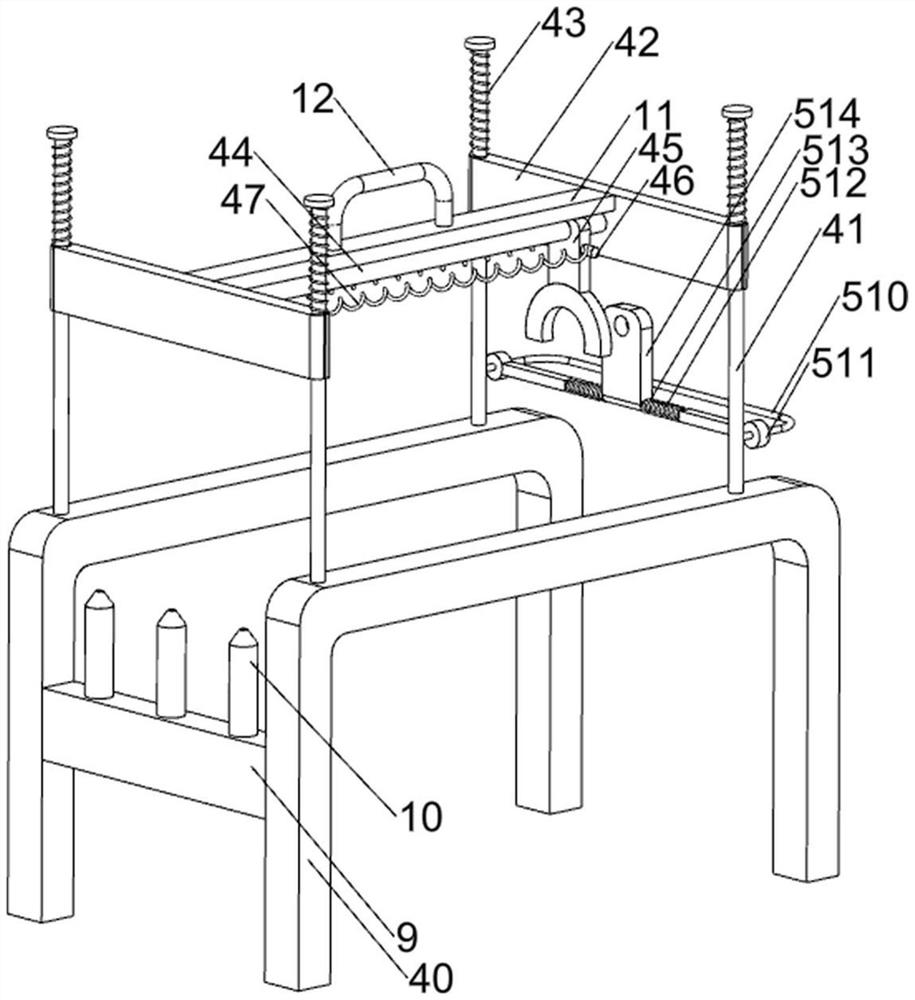

[0088]On the basis of Example 1, such asFigure 2-3 As shown, the connecting mechanism 4 includes a second support frame 40, a support rod 41, a first connecting plate 42, a first spring 43, a first connecting rod 44, a push plate 45, a second connecting rod 46, and a second spring 47. The top of the base 1 is symmetrically provided with the second support frame 40, and the upper portion of the second support frame 40 is respectively symmented with the support rod 41, and the upper portion is slidably equipped between the upper portion of the upper portion of the on-side support rod 41, the first connection A first spring 43 is provided between the top portion and the support rod 41, and the first spring 43 is hit on the support rod 41, and there is a first connecting rod 44 between the first connecting plates 42, and the first connecting rod 44. The sliding type is provided with a push plate 45, and a second connecting rod 46 is provided on the push plate 45, and a second spring 47 ...

Embodiment 3

[0092]On the basis of Example 2, such asFigure 4-6As shown, there is also a tensioning mechanism 6, the tensioning mechanism 6 includes a fourth support plate 60, a connecting ring 61, a fifth support plate 62, a rotor 63, a block 64, a fourth spring 65, a first roller 66 In the left side of the fifth connecting rod 67, the second support frame 40 is provided with a fourth support plate 60, and there is a connection ring 61 between the fourth support plates 60, and a plurality of fifth support plates 61 are provided with a uniform portion. The rotation type rolling rod 63 is provided between the adjacent two fifth support plates 62, and the pickup 64 is provided with a block 64, and a fourth spring 65 is provided between the block 64 and the connecting ring 61. Both the end portion of the block 64 is provided with a fifth connecting rod 67, and the first roller 66 is provided with a first roller 66.

[0093]When the post is slid to the left to the position of the connection ring 61, th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap