Wafer polishing head

A wafer and chuck technology, applied in the field of wafer grinding heads, can solve the problem of time required for replacement processes, and achieve the effects of realizing grinding steps, improving productivity, and achieving high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

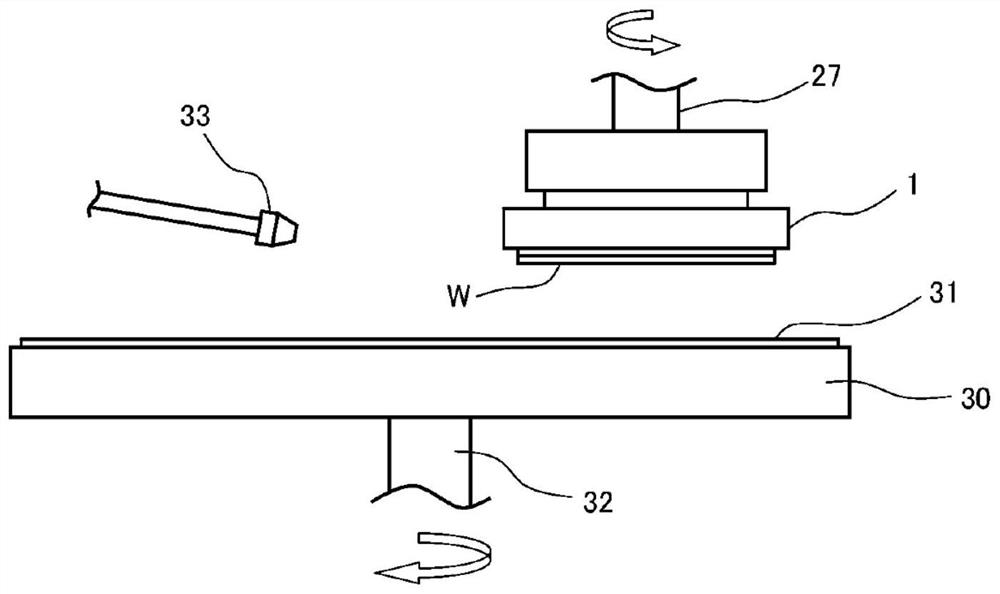

[0026] Hereinafter, the wafer polishing head 1 according to the embodiment of the present invention will be described in detail based on the drawings. figure 1 It is a figure which shows the schematic structure of the wafer polishing apparatus provided with the wafer polishing head 1 which concerns on embodiment of this invention.

[0027] refer to figure 1 , the wafer polishing head 1 is installed in the wafer polishing apparatus. The wafer polishing head 1 is a device for sucking and holding the wafer W in the process of polishing the wafer W. As shown in FIG. The wafer W is, for example, a semiconductor wafer.

[0028] The wafer polishing apparatus is an apparatus for polishing a wafer W. As shown in FIG. The wafer polishing apparatus has a freely rotatable table 30 , a liquid supply nozzle 33 , and a wafer polishing head 1 .

[0029] The table 30 is freely rotatably set on the platform. The table 30 is driven to rotate by a rotating shaft 32 by a driving device not sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com