Lug type tunnel gate for plastic pipefitting die

A technology of latent gate and plastic pipe fittings, which is applied in the field of bump-type latent gate of plastic pipe fitting molds, can solve the problems of inability to reach at the same time, weld marks, affecting the appearance of products, etc. beautiful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

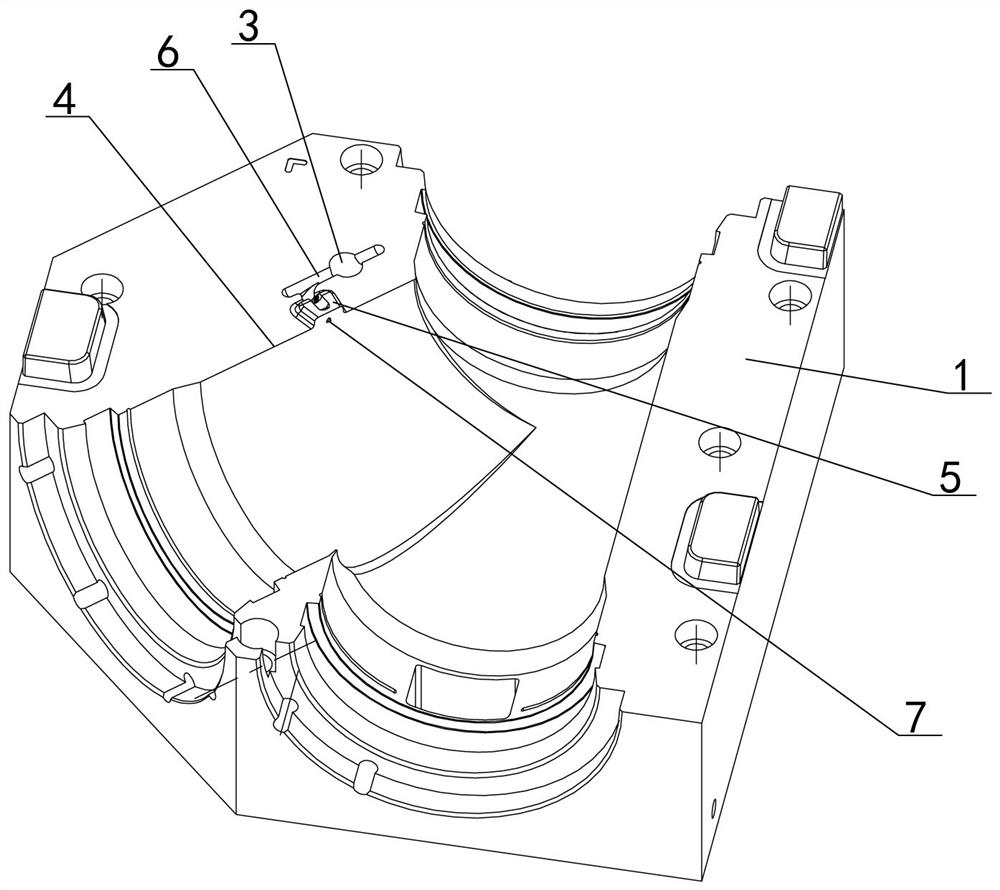

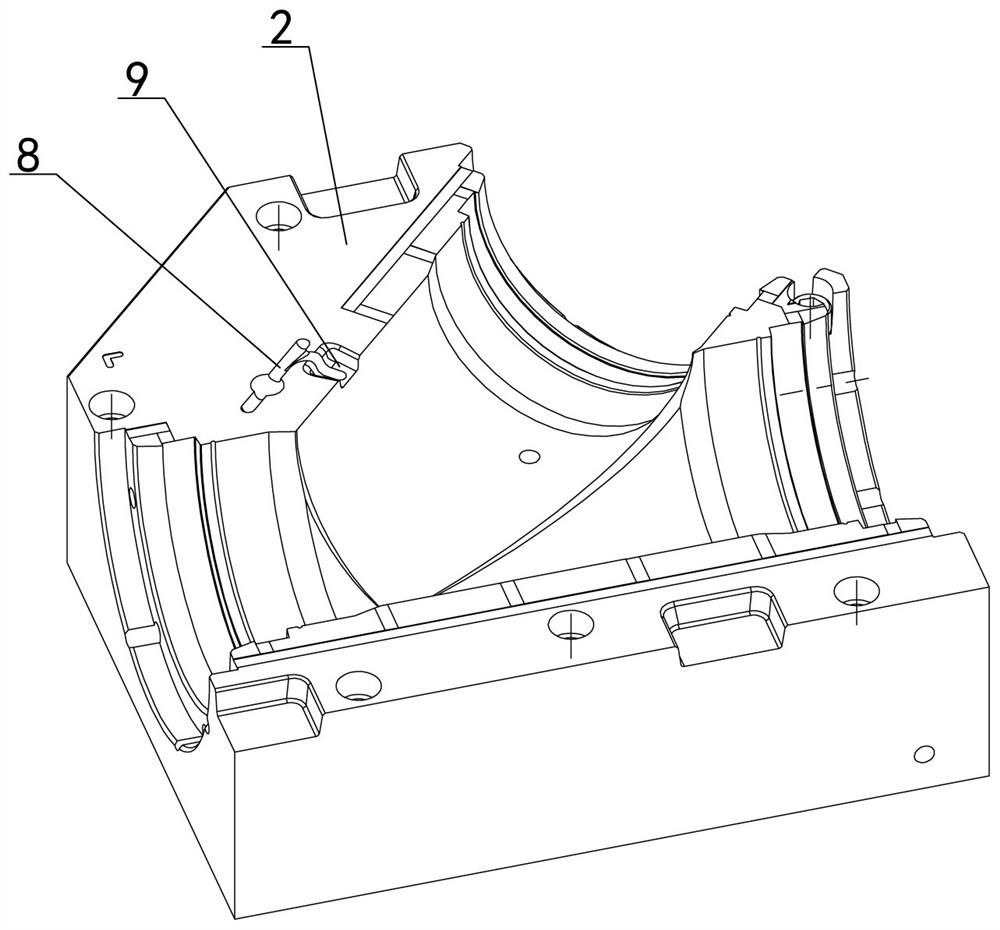

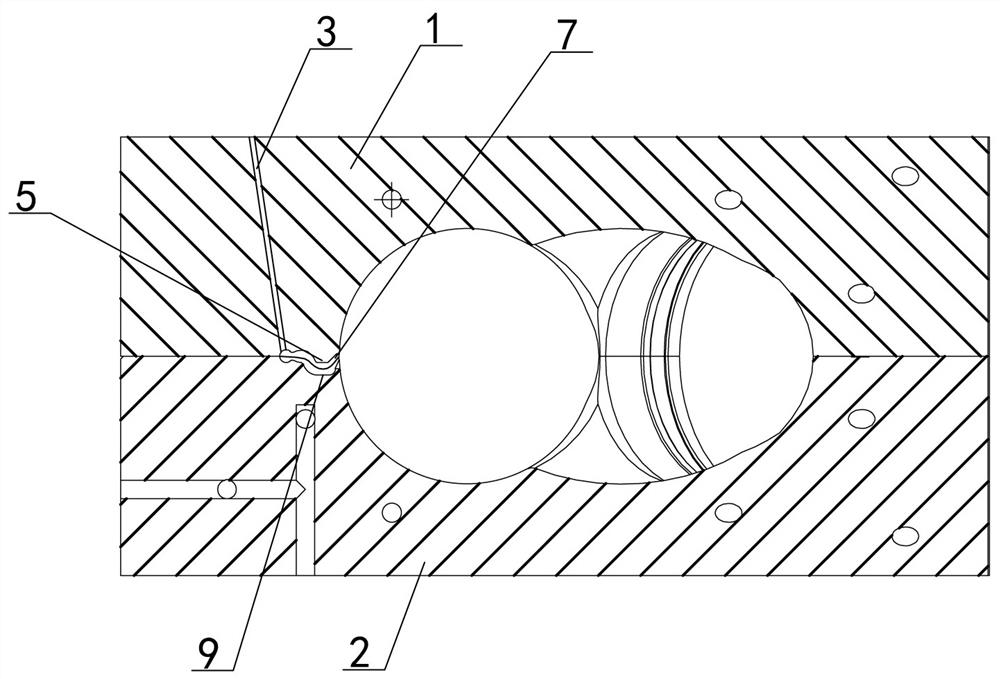

[0010] The invention relates to a plastic pipe fitting mold bump type latent gate, which comprises a mold cavity insert 1 and a core insert 2. A flow channel hole 3 is formed in the cavity insert 1. A bump 5 is set on the parting line 4 of the cavity insert, a cavity flow channel 6 is set between the bump 5 and the runner hole 3, a latent gate 7 is set in the bump, and the corresponding core insert 2 is set The core runner 8 and the groove 9, the bump 5 matches the groove 9, the cavity runner 6 matches the core runner 8, the latent gate 7 matches the cavity runner 6 and the core runner 8 connected. The main feature of this scheme is that a bump 5 is set on the parting line 4 of the cavity insert, and a latent gate 7 is set in the bump. After the plastic raw material enters, it flows evenly to both sides (cavity side and core side), and finally merges together. The joint is welded evenly, with less welding marks, beautiful appearance of the pipe fittings, and improved product ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com