A Ti35 Titanium Alloy Resistant to Nitric Acid Corrosion

A technology of titanium alloy and nitric acid, applied in the field of Ti35 titanium alloy, can solve the problems of unfavorable plasticity and processing performance of Ti-Ta-based materials, further improvement of plasticity, low strength and plasticity, etc., to achieve excellent corrosion resistance of nitric acid, easy to use Industrial application, overcoming the effect of low plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

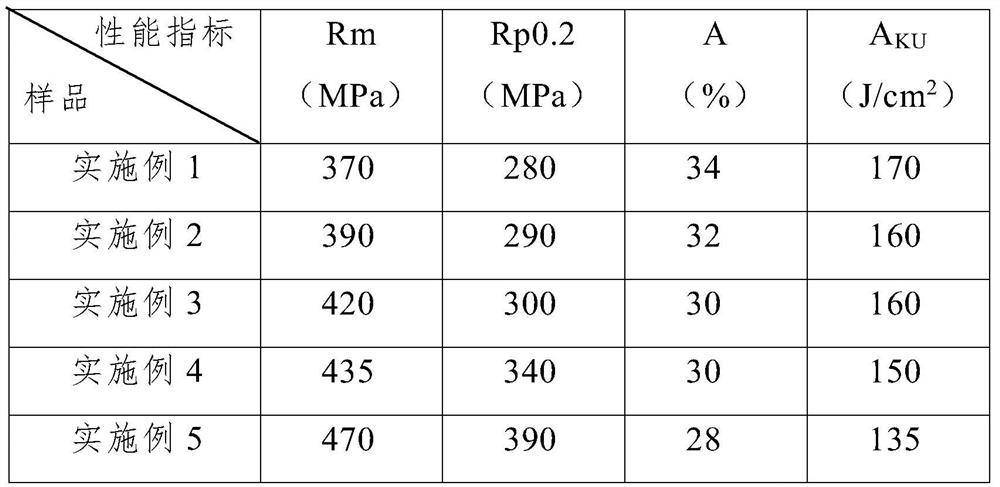

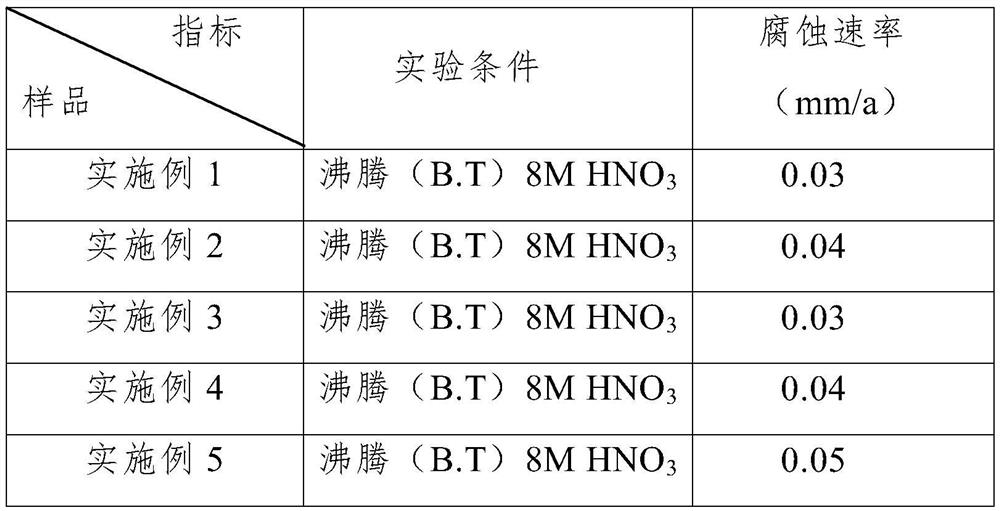

Embodiment 1

[0022] The nitric acid corrosion-resistant Ti35 titanium alloy of the present embodiment is made up of the composition of following mass content: tantalum 5.5%, oxygen 0.15%, surplus is titanium and unavoidable impurity; The mass of iron in the unavoidable impurity of described Ti35 titanium alloy The mass content of carbon is 0.11%, the mass content of carbon is 0.008%, the mass content of nitrogen is 0.003%, and the mass content of hydrogen is 0.0006%.

[0023] The preparation process of the nitric acid corrosion-resistant Ti35 titanium alloy of this embodiment is as follows: prepare raw materials according to the design composition and content of the target product, and then place the titanium powder and tantalum powder in the raw material in the mixer according to the mass ratio of 3:2 Mix for 5 hours to obtain a mixed powder with uniform composition, mix the mixed powder with titanium sponge, TiO 2 After batching, use a press to press into an electrode block, and place it...

Embodiment 2

[0025] The nitric acid corrosion-resistant Ti35 titanium alloy of the present embodiment is made up of the composition of following mass content: tantalum 5.7%, oxygen 0.13%, surplus is titanium and unavoidable impurity; The quality of iron in the unavoidable impurity of described Ti35 titanium alloy The mass content of carbon is 0.09%, the mass content of carbon is 0.004%, the mass content of nitrogen is 0.005%, and the mass content of hydrogen is 0.001%.

[0026] The preparation process of the Ti35 titanium alloy resistant to nitric acid corrosion of the present embodiment is: prepare the raw material according to the design composition and content of the target product, and then add sponge titanium, TiO 2Powder mixed with Ti-40%Ta intermediate alloy scraps, pressed into electrode blocks, placed in an oven at 80°C to dry for 4 hours, and then placed in a vacuum plasma welding box to be welded into consumable electrodes. The Ti35 titanium alloy ingot was smelted three times i...

Embodiment 3

[0028] The nitric acid corrosion resistant Ti35 titanium alloy of the present embodiment is made up of the composition of following mass content: tantalum 6%, oxygen 0.10%, surplus is titanium and unavoidable impurity; The mass of iron in the unavoidable impurity of described Ti35 titanium alloy The mass content of carbon is 0.010%, the mass content of carbon is 0.005%, the mass content of nitrogen is 0.003%, and the mass content of hydrogen is 0.0009%.

[0029] The preparation process of the Ti35 titanium alloy resistant to nitric acid corrosion of the present embodiment is: prepare the raw material according to the design composition and content of the target product, and then add sponge titanium, TiO 2 Powder mixed with Ti-40%Ta intermediate alloy scraps, pressed into electrode blocks, placed in an oven at 80°C to dry for 4 hours, and then placed in a vacuum plasma welding box to be welded into consumable electrodes. The Ti35 titanium alloy ingot was smelted three times in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com