Ti35 titanium alloy resistant to nitric acid corrosion

A titanium alloy and nitric acid technology, applied in the field of Ti35 titanium alloy, can solve the problems of unfavorable plasticity and processing performance of Ti-Ta-based materials, further improvement of plasticity, low strength and low plasticity, etc., to achieve excellent nitric acid corrosion resistance, and convenient Industrial application, the effect of overcoming low plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

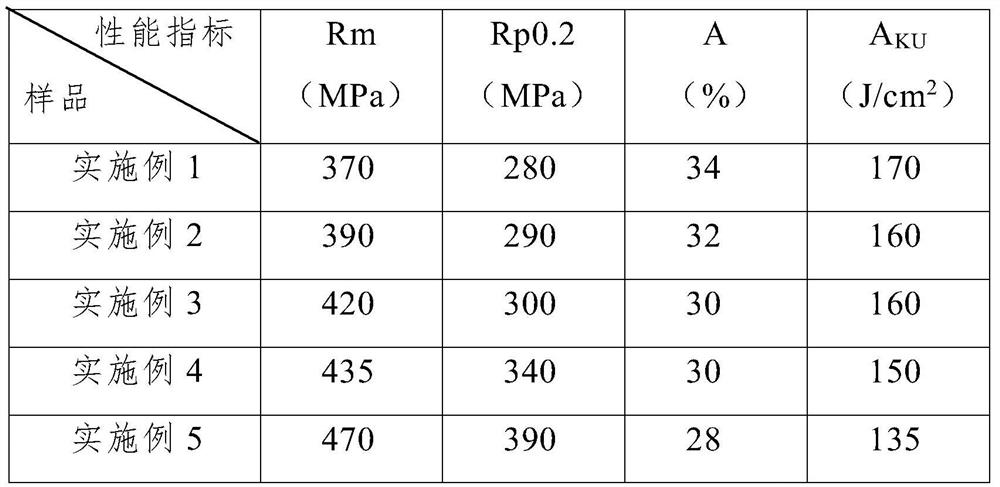

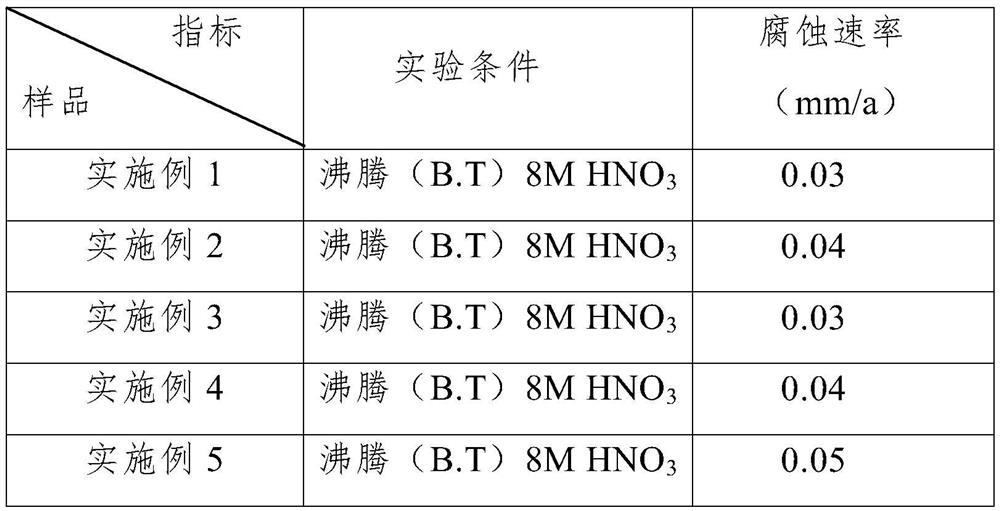

Embodiment 1

[0022]The ti35 titanium alloy of the nitric acid-resistant nitrate resistant to the following mass content is comprised of the following mass content: 5.5% oxygen, oxygen is 0.15%, the margin is titanium and inevitable impurities; the inevitable impurities of the Ti35 titanium alloy China The content is 0.11%, the mass content of carbon is 0.008%, and the quality content of nitrogen is 0.003%, and the mass content of hydrogen is 0.0006%.

[0023]The preparation process of the Ti35 titanium alloy of the nitric acid corrosion of the present embodiment is: according to the design component and content of the target product, then placed the titanium powder in the raw material to the mass ratio of 3: 2 in the mixer according to the mass ratio of 3: 2. Mix for 5 h, resulting in a uniform mixture of ingredients, combining powder and sponge, TiO2After the ingredients are pressed by pressing the electrode block, and then placed in an oven at 80 ° C for 4 h, then placed in a vacuum plasma weldin...

Embodiment 2

[0025]The ti35 titanium alloy of the nitric acid-resistant nitric acid-resistant nitrate is composed of the following mass content: 5.7% oxygen, oxygen is 0.13%, the margin is titanium and inevitable impurities; the inevitable impurities of the Ti35 titanium alloy The content of 0.09%, the mass content of carbon is 0.004%, and the quality content of nitrogen is 0.005%, and the mass content of hydrogen is 0.001%.

[0026]The preparation process of the Ti35 titanium alloy of the nitric acid corrosion of the present embodiment is: Preparing the material according to the design of the target product, the material is prepared, and then the sponge in the raw material, TiO2When the powder is mixed with Ti-40% TA, it is pressed into electrode block after mixing, and then placed in an oven at 80 ° C for 4 h, then placed in a vacuum plasma welding box to weld to self-consuming electrodes, and put the self-consumption electrode Three smelting in the vacuum self-consuming electric arc furnace was ...

Embodiment 3

[0028]The Ti35 titanium alloy of the nitric acid resistant etching of the present embodiment consists of the following mass content: 6%, oxygen 0.10%, the margin is titanium and inevitable impurities; the inevitable impurities of the Ti35 titanium alloy The content is 0.010%, and the mass content of carbon is 0.005%, and the quality content of nitrogen is 0.003%, and the mass content of hydrogen is 0.0009%.

[0029]The preparation process of the Ti35 titanium alloy of the nitric acid corrosion of the present embodiment is: Preparing the material according to the design of the target product, the material is prepared, and then the sponge in the raw material, TiO2When the powder is mixed with Ti-40% TA, it is pressed into electrode block after mixing, and then placed in an oven at 80 ° C for 4 h, then placed in a vacuum plasma welding box to weld to self-consuming electrodes, and put the self-consumption electrode Three smelting in the vacuum self-consuming electric arc furnace obtained ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com