Pavement flattening device for road construction

A technology of road construction and flattening machine, which is applied in the direction of roads, roads, road repairs, etc., and can solve the problem of difficulty in meeting different road surface flattening requirements, adjusting the flattening rollers for flattening use requirements, and affecting the use effect of road surface flattening and other issues to achieve the effect of improving adjustability and applicability, reducing assembly difficulty, and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0032] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

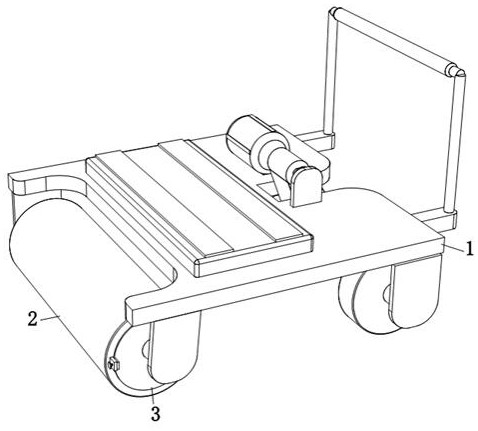

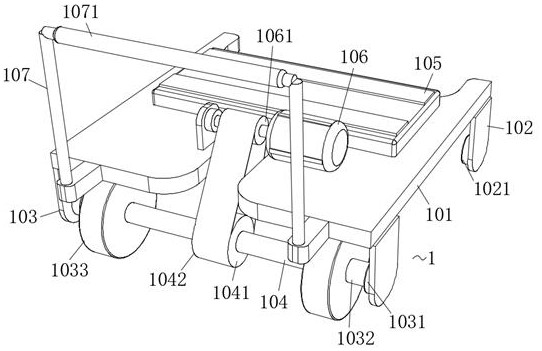

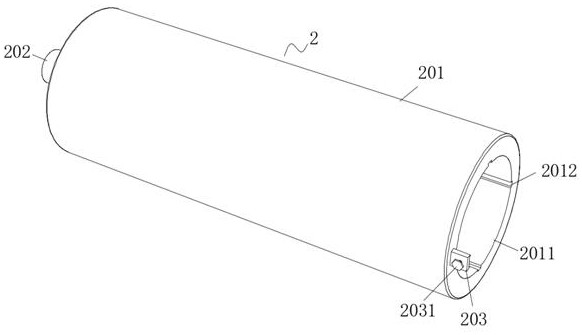

[0033] Such as Figure 1-Figure 5 As shown, the present invention is a road surface flattening device for road construction, comprising a frame assembly 1, the bottom end of the frame assembly 1 is provided with a roller assembly 2, and the inside of the roller assembly 2 is provided with a counterweight assembly 3;

[0034]The frame assembly 1 includes a flattening frame 101 and a transmission roller 104. The bottom side of the flattening frame 101 is hinged ...

no. 2 example

[0039] Based on the road surface flattening device for road construction provided in the first embodiment, the compaction operation on different road surfaces can be realized by changing the weight of the magnetic counterweight ring 303 in the flatten roller 201. The complexity of the road roller is different, and the weight of the magnetic counterweight ring 303 needs to be replaced frequently. At this time, the workload of the construction personnel is huge, and they cannot adapt more quickly, and the work efficiency is low. In order to further improve the adaptability and work efficiency of the road roller, combined with Figure 6 and 7 , a road surface flattening device for road construction also includes: the magnetic counterweight ring 303 itself not only has weight, but also makes it have a certain degree of magnetism during design, and ensures that the magnetic properties of the inner surface of the electromagnetic counterweight ring 303 are consistent, which can Assum...

no. 3 example

[0044] Based on the road surface flattening device for road construction provided in the second embodiment, the vibration of the flattened roller 201 can be controlled by changing the rotational speed of the electromagnetic eccentric rod 4 and the current of the energized coil, but in the actual operation process , due to the complexity of the road conditions, it is inevitable that there will be road debris attached to the flattening roller 201. If it is not dealt with in time at this time, it will affect the use of the flattening roller 201, and it cannot guarantee the safety of the road surface. Better compaction operation, in order to further solve the problem of cleaning up the sundries attached to the flattening roller 201, combined with Figure 7 and Figure 8 , a road surface flattening device for road construction also includes a magnetic counterweight ring 303 with a semicircular opening on the side away from the assembly plate 301, and the semicircular design will no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com