Wallboard mounting structure convenient to mount and dismount and mounting process thereof

A technology for installing structures and wall panels, applied in the direction of walls, building components, building structures, etc., can solve the problem of non-disassembly and recycling, and achieve the effect of shortening the construction process, convenient operation, and easy maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

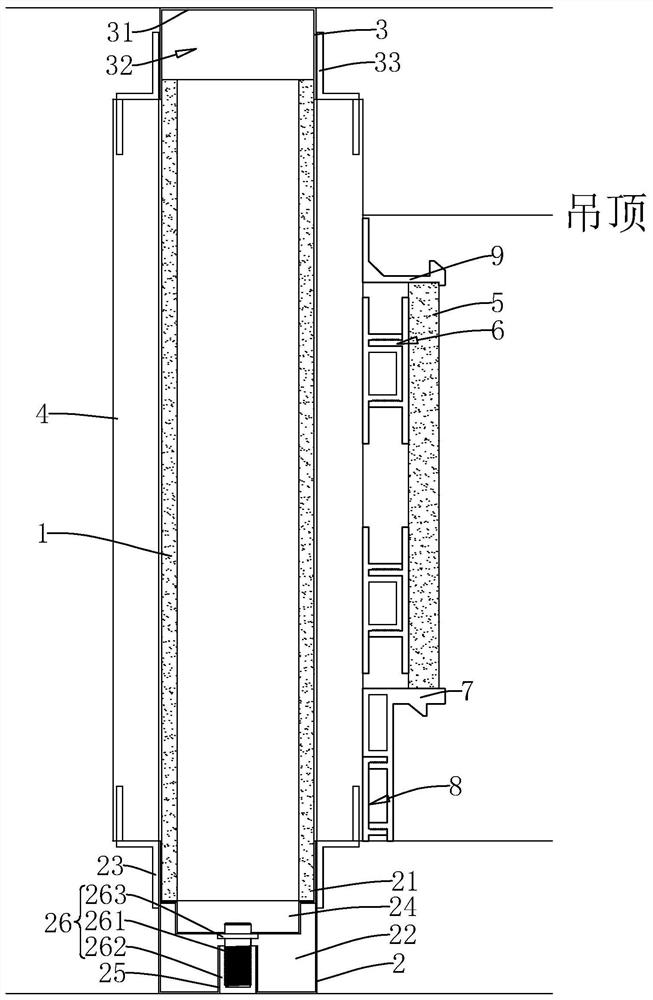

[0050] The following is attached Figure 1-6 The application is described in further detail.

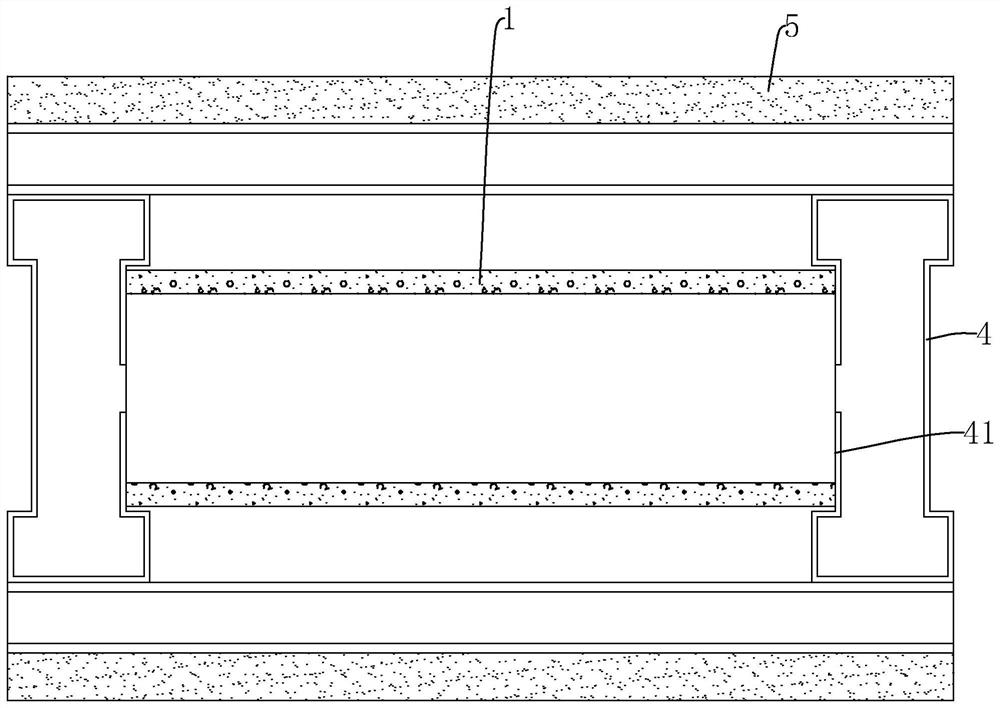

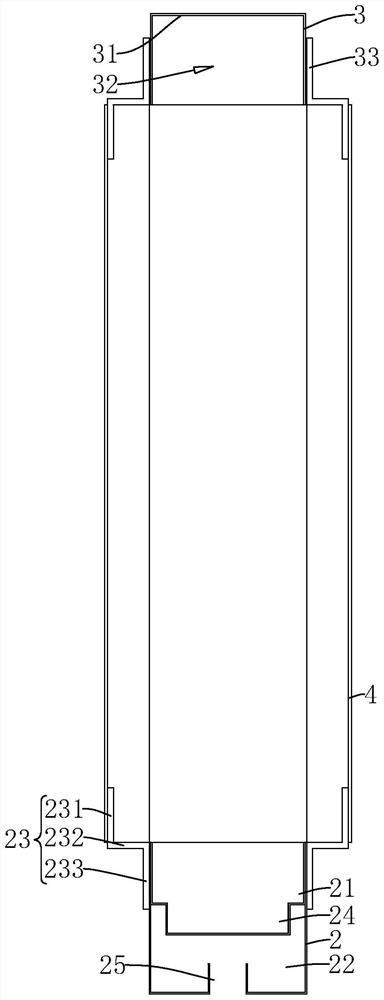

[0051] The embodiment of the present application discloses a wall panel installation structure that is convenient for installation and disassembly. refer to figure 1 with figure 2 The wall panel installation structure includes a prefabricated wall panel 1, a ground keel 2 fixed on the ground and a sky keel 3 fixed on the indoor roof.

[0052] The ground keel 2 can be a profile, and can also be bent and formed from a steel plate. A first accommodating groove 21 for embedding the prefabricated wall panel 1 is formed on the upper side of the ground keel 2 . The sky keel 3 can be a section bar or a bent steel plate, which is in an inverted U shape as a whole, with the opening facing downward to form a second accommodating groove 31 for inserting the prefabricated wall panel 1 . There are multiple prefabricated wall panels 1 , and both ends of each prefabricated wall panel 1 are ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com